Why Uneven Sidewalks Are More Than Just an Eyesore

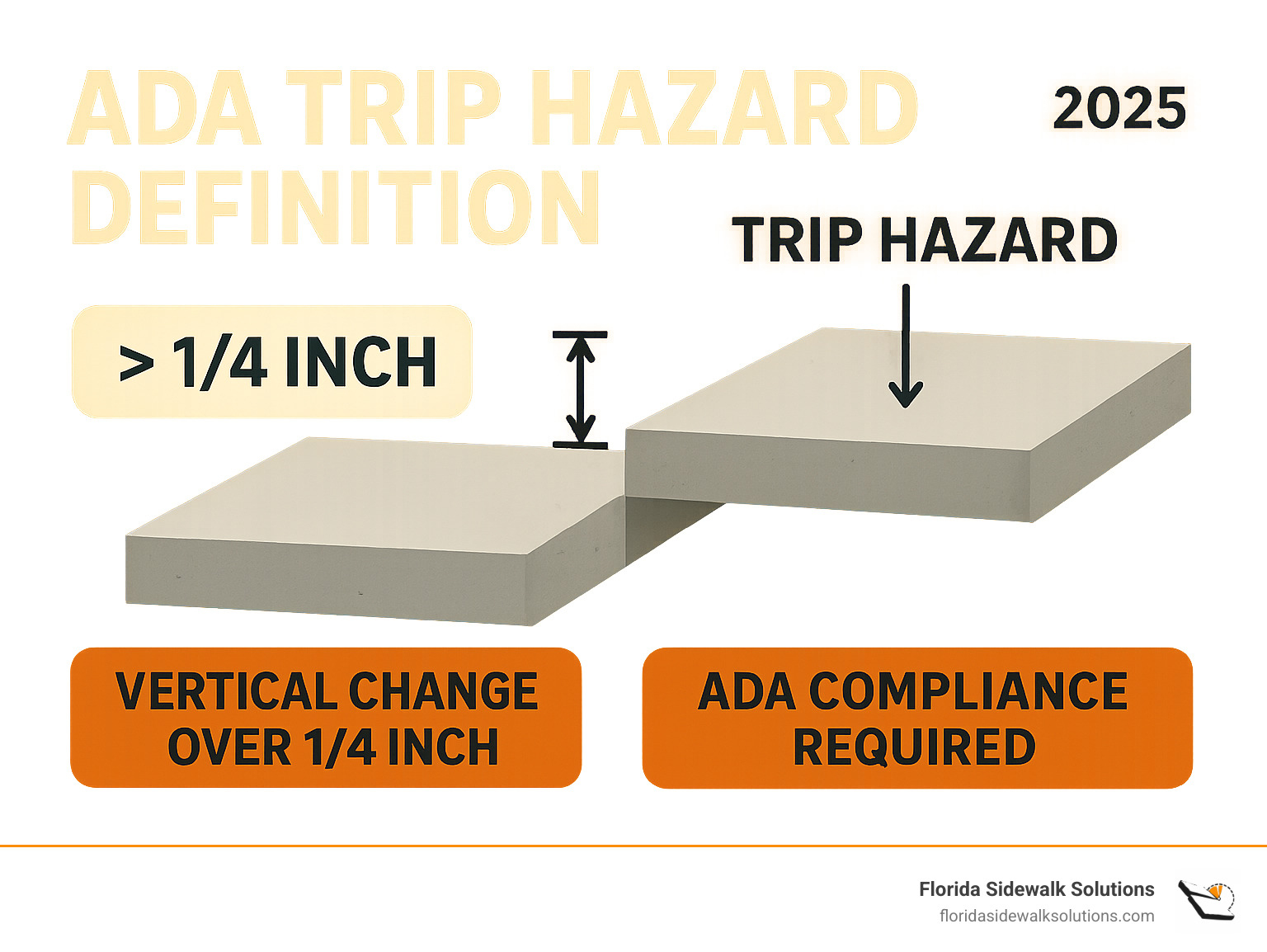

Sidewalk trip hazard repair is a critical safety and compliance issue that affects millions of property owners and municipalities across the country. When concrete sidewalk panels become uneven – creating vertical changes of more than 1/4 inch – they pose serious risks to pedestrians and significant liability concerns for property owners.

Quick Answer for Sidewalk Trip Hazard Repair:

- What it is: Fixing uneven concrete panels that create vertical changes over 1/4 inch

- Main methods: Precision cutting, grinding/scabbling, or complete replacement

- Best solution: Precision concrete cutting (70-90% cheaper than replacement)

- Time required: Hours instead of days with modern cutting methods

- ADA compliance: Required for all public walkways under federal law

Uneven sidewalks aren’t just unsightly – they’re dangerous. Trip hazards cause thousands of injuries annually and can result in costly lawsuits for property owners. The Americans with Disabilities Act (ADA) defines any vertical change over 1/4 inch as a trip hazard, making compliance a legal requirement for public walkways.

For municipal maintenance managers facing budget constraints, the challenge is finding repair solutions that are both effective and economical. Traditional methods like concrete grinding often fall short, while complete sidewalk replacement can cost 70-90% more than necessary.

Modern precision cutting technology offers a superior alternative – creating smooth, ADA-compliant walkways without the expense and disruption of traditional repair methods.

Sidewalk trip hazard repair word guide:

- american with disabilities act accessibility guidelines sidewalks

- curb ramp

- ada compliant ramp specifications

Understanding Sidewalk Trip Hazards: Causes and Consequences

Picture this: you’re walking down the sidewalk, maybe checking your phone or chatting with a friend, when suddenly your toe catches on an uneven slab. That heart-stopping moment when you stumble forward isn’t just embarrassing – it’s dangerous. But what exactly transforms an innocent crack or bump into a legitimate “trip hazard,” and why should property owners lose sleep over them? Understanding these concrete culprits is essential for effective sidewalk trip hazard repair.

What Legally Constitutes a Trip Hazard?

The definition of a trip hazard isn’t left to guesswork – the Americans with Disabilities Act (ADA) provides crystal-clear guidelines. According to ADA standards, any vertical displacement of more than 1/4 inch at joints or cracks officially qualifies as a trip hazard. That’s roughly the thickness of six stacked pennies.

This quarter-inch rule might seem nitpicky, but there’s solid reasoning behind it. The standard ensures that accessible pathways remain safe for everyone – from someone using a wheelchair to a parent pushing a stroller to an elderly person with a walker. Even that seemingly minor bump can spell disaster for anyone with mobility challenges or visual impairments.

When sidewalk panels shift beyond this 1/4-inch threshold, they create unexpected obstacles that can easily catch people off guard. That’s where proper sidewalk trip hazard repair becomes crucial for maintaining ADA compliance. For a deeper dive into these regulations, check out Trip Hazards and the ADA Rules. You can also explore Paving the Way: Understanding ADA Sidewalk Standards and find comprehensive information from the U.S. Access Board.

Common Causes of Uneven Sidewalks

Sidewalks face a constant battle against forces determined to make them uneven. Here in Florida, tree root growth tops the list of troublemakers. Those beautiful oak and palm trees that provide shade and character? Their roots don’t care about property lines or concrete barriers. As trees mature, their roots spread and thicken beneath sidewalk panels, creating enormous pressure that can lift entire slabs several inches.

Soil erosion presents another major challenge, especially during Florida’s intense rainy seasons. Heavy downpours and inadequate drainage systems can wash away the supporting soil beneath concrete slabs. Without this crucial foundation, panels sink and tilt, creating dangerous uneven surfaces.

Ground compaction issues often trace back to original construction. When soil isn’t properly compacted before concrete placement, it continues settling over time. This gradual settling causes panels to sink and become uneven – sometimes years after installation.

Water damage extends beyond simple erosion. Water seeping into cracks can gradually weaken concrete and shift the supporting base. Even in Florida’s mild climate, repeated wet-dry cycles can cause concrete to expand and contract, widening existing cracks and creating new displacement issues.

Finally, poor installation practices set sidewalks up for premature failure. Inadequate base preparation, improper joint spacing, or substandard concrete mixing can create problems that surface months or years later. For insights into addressing these various damage types, see our guide on Damaged Florida Sidewalk repair solutions.

The High Cost of Neglect: Risks and Liabilities

Ignoring a trip hazard might seem like a minor oversight, but the consequences can be devastating – both financially and legally. For property owners and municipalities, unaddressed sidewalk hazards represent ticking time bombs of liability.

Personal injury lawsuits pose the most immediate threat. A single fall can result in anything from minor scrapes to severe fractures, head injuries, or permanent disabilities. The resulting legal battles often involve substantial attorney fees, settlement costs, and potential punitive damages that can reach six figures. What starts as a small crack can quickly escalate into major litigation, as detailed in our article about Sidewalk Trip Hazard Lawsuit cases.

Municipal fines add another layer of financial pressure. City inspectors regularly patrol for ADA violations and safety hazards. When they identify non-compliant sidewalks, property owners face citations with tight repair deadlines. Failing to address these violations results in escalating penalties that compound over time.

Insurance claims create long-term financial strain. While liability coverage might handle initial costs, repeated claims lead to higher premiums or policy cancellations. Insurance companies don’t appreciate properties that generate frequent trip-and-fall incidents.

The property owner responsibility varies by location, but many jurisdictions hold adjacent property owners liable for sidewalk maintenance. This means the sidewalk in front of your business or home becomes your legal responsibility – and your potential liability. Taking proactive steps to Remove Sidewalk Liabilities isn’t just smart risk management – it’s essential protection against costly legal consequences.

The bottom line? Delaying sidewalk trip hazard repair isn’t just risky – it’s financially reckless.

The Florida Sidewalk Solutions Method: Precision Trip Hazard Repair

When it comes to sidewalk trip hazard repair, there’s the old way of doing things, and then there’s the smart way. At Florida Sidewalk Solutions, we’ve developed something truly different – a method that doesn’t just patch the problem but actually solves it for good. Our precision cutting approach represents a complete rethinking of how sidewalk repairs should be done.

The difference starts with our technology. While others are still using methods that create dust clouds and leave rough surfaces, we’re using specialized equipment that makes surgical-precise cuts. It’s the kind of innovation that makes you wonder why anyone still does it the old way.

How the Precision Cutting Process Works

Here’s where things get interesting. Our Patented Sidewalk Cutting Technology allows us to make horizontal cuts directly into the raised concrete panel. We’re not just grinding away at the surface – we’re creating a perfectly engineered slope that transforms a dangerous trip hazard into a smooth, ADA-compliant walkway.

The magic happens when our specialized equipment cuts the higher panel to create that crucial 1:12 slope ratio required by ADA standards. The result? A beveled, slip-resistant finish that provides a seamless transition between panels. No jarring edges, no rough patches – just a smooth pathway that feels completely natural underfoot.

What really sets us apart is our precision. We can work right up to building walls, around utility covers, and in those tricky spots where traditional equipment simply can’t reach. Adjacent panels remain completely undamaged throughout the process, and there’s no disruption to landscaping or underground utilities.

The best part? The moment we finish cutting, pedestrians can use the sidewalk immediately. No waiting for concrete to cure, no “wet cement” signs, no detours. It’s immediate pedestrian access that keeps businesses running and communities moving. You can learn more about Why is Concrete Cutting the Best Sidewalk Repair Method?.

Advantages Over Conventional Methods

Traditional sidewalk trip hazard repair methods often feel like trying to fix a watch with a hammer. Grinding and scabbling equipment creates enormous amounts of dust and debris, requires extensive cleanup, and often can’t reach the edges where many trip hazards actually occur. It’s messy, disruptive, and frankly, not very effective.

Our precision cutting method changes everything. We’re more effective than grinding or scabbling because we create a true, engineered slope rather than just wearing down the surface. While grinders struggle with edges and corners, our equipment reaches edges and expansion joints with surgical precision, ensuring every inch of the hazard is eliminated.

The cleanliness factor is remarkable. Instead of creating clouds of concrete dust that settle on everything nearby, our process produces no dust or slurry. We collect debris as we work, leaving the area cleaner than many traditional methods ever could.

Most importantly, we deliver consistent ADA compliance with every cut. There’s no guesswork, no “close enough” – our method creates the exact slope specifications required by federal accessibility standards. This means property owners can have complete confidence in their liability protection.

The efficiency speaks for itself. While traditional methods might take days and require extensive site preparation and cleanup, our precision cutting typically completes repairs in hours with minimal disruption. It’s a completely different experience for everyone involved.

For property managers and municipal officials exploring their options, understanding the full range of available solutions is crucial. You can explore more about Options to Remove Sidewalk Hazards to see how our method compares to traditional approaches.

Comparing Your Options: Why Precision Cutting Wins

When you’re faced with a sidewalk trip hazard, you essentially have three paths forward: grinding or scabbling, complete replacement, or our precision cutting method. Each has its place, but understanding the real-world differences can save you both money and headaches down the road.

Let’s be honest – sidewalk trip hazard repair shouldn’t break your budget or shut down your property for weeks. That’s why we’ve put together this comparison to show you exactly what each method delivers:

| Feature / Method | Conventional Methods (Grinding/Scabbling) | Complete Replacement | Florida Sidewalk Solutions Precision Cutting |

|---|---|---|---|

| Cost | Moderate (can be higher than cutting for full compliance) | High (most expensive option) | Low (70-90% savings compared to replacement) |

| Speed | Moderate (can be slow to achieve desired results) | Slow (requires demolition, pouring, curing) | Fast (repairs completed in hours, not days) |

| ADA Compliance | Often partial or inconsistent; may leave residual hazards | Full (but at high cost and disruption) | Full and consistent (guaranteed 1:12 slope) |

| Disruption | Moderate (noise, dust, potential for repeat work) | High (sidewalk closures for days/weeks, heavy equipment) | Minimal (low noise, no dust/slurry, immediate access) |

| Longevity of Repair | Varies; can degrade faster if not fully resolved | High (new concrete) | High (stable, precise cut maintains integrity) |

| Aesthetics | Can leave unsightly marks, discolored patches, or uneven textures | New, uniform appearance | Clean, smooth, and natural-looking finish |

| Environmental Impact | Dust, slurry waste, high energy use | Significant concrete waste, high energy use | Minimal waste (collected debris), lower energy use |

| Access to Edges/Joints | Limited; often cannot fully resolve hazards at edges or expansion joints | Full (new pour) | Excellent; precise cuts at edges and around obstacles |

The numbers tell a compelling story, but the real difference becomes clear when you consider your specific situation. Are you managing a busy commercial property where downtime costs money? Do you have budget constraints that make full replacement unrealistic? Our precision cutting method addresses these real-world challenges in ways that traditional methods simply can’t match.

For more detailed cost analysis, check out the Cheapest Sidewalk Repair Method to understand why smart property managers choose precision cutting.

The Cost-Effectiveness of Precision Trip Hazard Repair

Here’s where the rubber meets the road – or in our case, where the budget meets the sidewalk. Cost savings of 70-90% compared to replacement isn’t just a marketing claim; it’s the reality that property managers and municipal officials experience when they choose our precision cutting method for sidewalk trip hazard repair.

Think about what those savings mean for your bottom line. If you’re facing a $10,000 sidewalk replacement project, our method could potentially reduce that to $1,000-$3,000. That’s not pocket change – it’s budget-changing money that can be redirected to other critical maintenance needs or improvements.

But the savings go beyond the initial repair cost. Every unaddressed trip hazard is a lawsuit waiting to happen. Personal injury claims can easily reach six figures, and that’s before you factor in legal fees, increased insurance premiums, and potential municipal fines for ADA non-compliance. Our method eliminates these risks completely, providing what we like to call “insurance you can walk on.”

The beauty of our approach is that it delivers long-term value without compromise. While grinding might seem cheaper upfront, it often leaves residual hazards or creates new ones, leading to repeat work and continued liability. Our precision cutting creates a permanent, ADA-compliant solution that stands the test of time.

We’re proud to offer truly Cost-Effective Sidewalk Repair that doesn’t sacrifice quality for savings. When you’re searching for Affordable Sidewalk Repair Near Me, we deliver both affordability and excellence.

Efficiency and Minimal Disruption

Nobody wants their sidewalk to become a construction zone for weeks on end. Whether you’re managing a retail center, school campus, or residential community, disruption equals problems – and problems cost money in ways that don’t always show up on repair invoices.

Our precision cutting method transforms what used to be a major disruption into a minor inconvenience. Most repairs are completed in hours, not days or weeks. This means your pedestrians aren’t forced to steer around barriers, your businesses don’t lose foot traffic, and your daily operations continue virtually uninterrupted.

The moment we finish cutting, the sidewalk is ready for use. There’s no waiting for concrete to cure, no “wet cement” signs, no roped-off areas creating bottlenecks. Immediate pedestrian access is a game-changer, especially for high-traffic areas where accessibility is crucial.

We also take pride in being good neighbors during the repair process. Our equipment operates with minimal noise pollution – a far cry from the jackhammering and heavy machinery associated with replacement projects. And unlike grinding methods that can create clouds of concrete dust, our system collects debris as we work, resulting in no dust or messy slurry that needs extensive cleanup.

This clean, quiet approach is what makes our service truly Non-Invasive Sidewalk Repair. We respect your space, your schedule, and your peace of mind while delivering superior results for your sidewalk trip hazard repair needs.

Frequently Asked Questions about Sidewalk Trip Hazard Repair

We love talking about sidewalk trip hazard repair because we know it can feel overwhelming when you’re trying to figure out the best solution for your property. Over the years, we’ve heard just about every question you can imagine, and we’re always happy to share what we’ve learned. Here are the questions that come up most often:

How long does a typical sidewalk repair take?

This is probably the first thing everyone wants to know, and honestly, we don’t blame you! When you’ve got a trip hazard that needs fixing, time is everything – especially if you’re dealing with a busy sidewalk or commercial property where every hour of disruption matters.

Here’s the thing: the timeline for sidewalk trip hazard repair depends entirely on which method you choose, and the difference is pretty dramatic.

If you go the traditional route with concrete removal and replacement, you’re looking at a multi-day ordeal. First comes the demolition (noisy and messy), then the new concrete pour, and finally the waiting game. Concrete needs time to cure properly before anyone can walk on it safely – we’re talking days, sometimes even weeks depending on the weather and the specific mix used. That’s a lot of disruption for what might be a relatively small problem.

Our precision cutting method? We’re talking hours, not days. Our specialized equipment allows us to assess the situation, make our precise cuts, and clean up efficiently. Once we’re done, the sidewalk is immediately ready for foot traffic. No waiting around, no extended closures, no frustrated pedestrians trying to find alternate routes. It’s one of the biggest advantages of choosing a smarter repair method.

Is repairing a sidewalk better than replacing it?

We get this question a lot, and it’s a smart one to ask. The short answer is: in most cases, absolutely yes. Sidewalk trip hazard repair through our precision cutting method offers some compelling advantages over full replacement.

Let’s talk money first, because we know that’s important. Our repair method can save you 70-90% compared to replacement costs. Think about that – you could be looking at thousands of dollars in savings just by choosing repair over replacement. That’s money you can use for other important property maintenance or improvements.

Then there’s the environmental angle. Replacement means tearing out perfectly good concrete and hauling it to a landfill, then manufacturing and transporting new materials. It’s wasteful when you think about it – why throw away an entire sidewalk panel when only the uneven joint needs attention? Our approach creates minimal waste and makes the most of existing materials.

The disruption factor is huge too. Replacement projects can shut down sidewalks for days or weeks, affecting businesses, residents, and anyone who needs to get around. Our repairs cause minimal disruption and get people back to their normal routines quickly.

Now, we’re not saying replacement is never the right choice. If a sidewalk is severely cracked throughout, crumbling, or has widespread structural damage, replacement might be necessary. But for trip hazards caused by settling, root damage, or minor shifting? Repair is usually the smarter, more economical choice. You can dive deeper into this topic in our comparison of Concrete Repairs vs Replacement.

Who is responsible for sidewalk repairs?

This is where things can get a bit tricky, because the answer depends on where you live and what type of property you’re dealing with. Understanding responsibility for sidewalk trip hazard repair is crucial for avoiding liability issues down the road.

In most areas, if you’re a property owner, you’re responsible for maintaining the sidewalk that runs along your property line. This might seem unfair – after all, it’s a public walkway – but that’s how most municipal regulations work. Whether you own a single-family home, a commercial building, or manage rental properties, you’re typically on the hook for keeping those sidewalks safe and hazard-free.

For homeowner associations, the responsibility usually falls to the HOA for all common areas and community sidewalks. This means the HOA board needs to stay on top of regular inspections and address hazards promptly to protect both residents and the association from potential lawsuits.

Municipalities handle their own properties – parks, government buildings, and sometimes major public thoroughfares – though this varies by location. They also enforce sidewalk maintenance standards and can issue citations to property owners who let hazards go unaddressed.

The bottom line? It’s worth checking with your local public works department to understand exactly what your responsibilities are. But regardless of who’s technically responsible, addressing trip hazards quickly is always the smart move. The cost of proactive repair is nothing compared to the potential expense of a lawsuit or municipal fine. This is exactly why we recommend reading about Why You Should Hire a Sidewalk Repair Contractor – professional expertise can save you both time and money while ensuring the job is done right.

Your Next Step to Safe, Compliant Walkways

Taking care of sidewalk trip hazard repair isn’t just about checking a box on your maintenance list – it’s about creating a safer world for everyone who walks through your community. Throughout this guide, we’ve explored why those seemingly small cracks and uneven spots can lead to big problems, and more importantly, how modern solutions can fix them efficiently and affordably.

The reality is that every day you delay addressing sidewalk trip hazards, you’re rolling the dice with pedestrian safety and your own liability. But here’s the good news: you don’t have to choose between doing the right thing and protecting your budget. Proactive maintenance with the right repair method can save you thousands while ensuring everyone can walk safely.

What we’ve learned is that precision cutting technology offers something truly in sidewalk repair. Instead of the old “tear it out and start over” mentality, we can now address trip hazards with surgical precision. This means your walkways can go from liability risks to safe, compliant pathways in a matter of hours, not weeks.

The difference between reactive and proactive approaches is striking. Waiting until someone gets hurt or until the city sends a violation notice puts you in crisis mode. But when you address hazards before they become problems, you’re in control. You’re choosing long-term solutions that protect both people and your investment.

For property managers and municipal officials especially, this approach makes perfect sense. You get ADA compliance, reduced liability, and significant cost savings all in one solution. It’s the kind of win-win that makes budgeting easier and communities safer.

Safety and compliance don’t have to be expensive or disruptive anymore. With modern sidewalk trip hazard repair methods, you can address hazards quickly, cleanly, and affordably. Your pedestrians get safer walkways, and you get peace of mind knowing you’ve done the right thing.

Ready to transform your uneven sidewalks into smooth, accessible pathways that everyone can use safely? The next step is simple: reach out to learn how precision cutting can solve your sidewalk challenges. Let’s work together to Level Up: Achieving ADA Compliance for Your Sidewalks and create walkways that truly serve your community.