What Are Concrete Grinding Solutions for Sidewalk Safety?

Concrete grinding solutions are specialized methods used to level uneven sidewalk surfaces and eliminate dangerous trip hazards. These solutions use abrasive tools and cutting techniques to create smooth, ADA-compliant walkways that protect pedestrians from falls and reduce municipal liability.

Quick Answer: Top Concrete Grinding Solutions for Trip Hazards

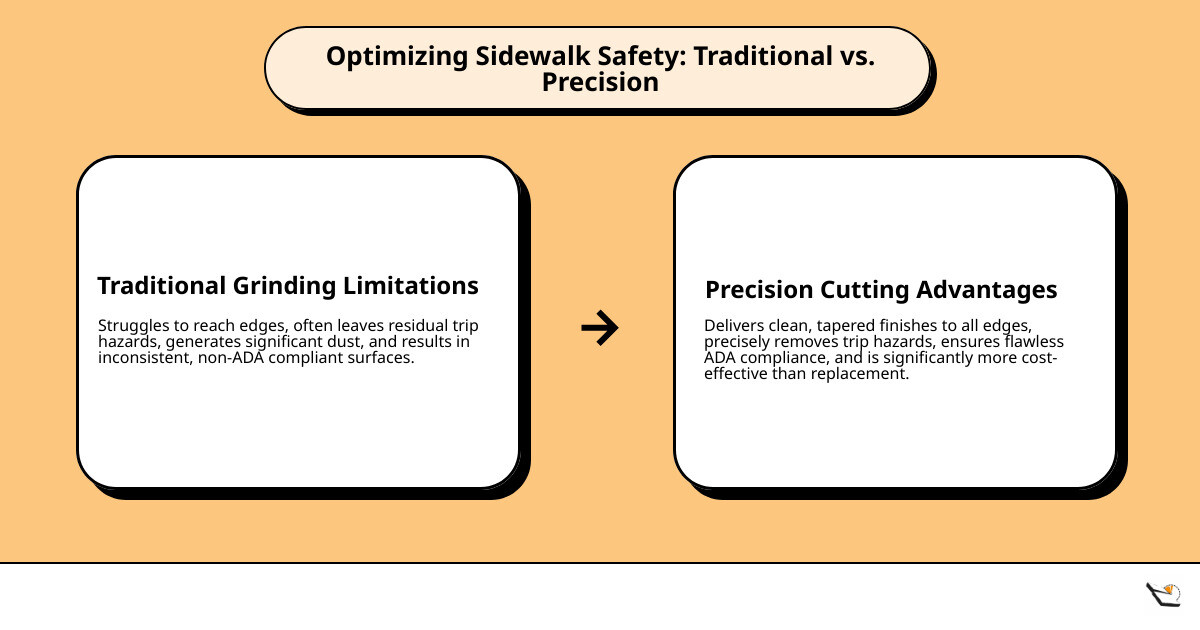

- Traditional Grinding – Uses abrasive tools but struggles with edges and creates dust

- Scabbling – Mechanical surface removal but leaves rough finishes

- Precision Concrete Cutting – Advanced cutting method that reaches all edges cleanly

- Full Replacement – Complete removal and replacement (most expensive option)

For municipal maintenance managers dealing with budget constraints and ADA compliance requirements, understanding these options is crucial. The Americans with Disabilities Act defines a trip hazard as any vertical change of 1/4 inch or more at joints or cracks – making precise repair methods essential.

Traditional concrete grinders face significant limitations when addressing sidewalk trip hazards. As noted in industry research, “Grinders are unable to reach the edges of the sidewalk or grind the sidewalk level with the next concrete panel, so the trip hazard often remains.” This creates ongoing liability issues and fails to meet ADA standards.

The challenge gets worse when you consider:

- Dust creation that disrupts pedestrian traffic

- Inability to achieve consistent edge-to-edge leveling

- Higher long-term costs due to incomplete repairs

- Potential insurance liability from remaining hazards

Modern precision cutting methods have emerged as superior alternatives, offering clean finishes that reach every edge while maintaining ADA compliance. These advanced solutions can cost as little as 1/10th the price of full sidewalk replacement while delivering better results than traditional grinding.

Simple Concrete grinding solutions glossary:

The Florida Sidewalk Solutions Approach: Precision Concrete Cutting for Trip Hazards

When it comes to fixing sidewalk trip hazards, we’ve learned that doing it right the first time saves everyone time, money, and headaches. That’s why our approach at Florida Sidewalk Solutions goes beyond traditional concrete grinding solutions – we use a method called precision concrete cutting that transforms dangerous, uneven sidewalk panels into perfectly level, safe walkways.

Our patented process works by making a clean, precise cut that removes the raised portion of concrete causing the trip hazard. Think of it like using a sharp knife instead of sandpaper – you get a much cleaner, more accurate result. This means we need minimal surface preparation, and the entire process is dust-free, creating a safer, cleaner environment for everyone walking by.

What really sets us apart is our specialized sidewalk cutting equipment that handles edge-to-edge repair. While traditional grinding tools can’t reach the edges where sidewalk panels meet, our technology covers every inch of the problem area. This comprehensive approach ensures the entire hazard disappears, leaving no lingering bumps or rough spots that could create new problems down the road.

We’re not just patching up a problem – we’re creating a long-term solution that blends seamlessly with your existing sidewalk. This commitment to superior results helps you achieve full ADA compliance while protecting against costly trip and fall liability. For more details on how we handle these challenging repairs, check out our comprehensive guide on sidewalk trip hazard repair.

Understanding the Precision Cutting Process

Our precision cutting process relies on patented equipment that creates a clean, tapered finish in the concrete. Picture slicing through a loaf of bread with a perfectly sharp knife – that’s the level of precision we achieve, but with concrete that’s often decades old and incredibly tough.

The tapered finish isn’t just about looks (though it does look great). This angled cut creates a smooth transition that eliminates the abrupt edge that causes people to trip in the first place. It’s engineering that prioritizes both safety and aesthetics.

One of the biggest advantages our clients notice immediately is our superior dust management. Traditional grinding creates clouds of concrete dust that can shut down sidewalks, irritate pedestrians, and create cleanup nightmares. Our process is virtually dust-free, which means less disruption for everyone and minimal cleanup afterward.

Our highly trained operators bring years of experience to every job. They understand exactly how to use this advanced technology to deliver consistent, ADA-compliant results every single time. It’s the perfect combination of cutting-edge engineering and skilled craftsmanship.

Applications for Concrete Cutting

Our precision concrete cutting method tackles the most critical sidewalk safety challenges that property managers and municipalities face every day. For trip hazard removal, we precisely eliminate those dangerous vertical changes that cause falls and create liability issues. The process removes exactly what needs to go while preserving the integrity of the surrounding concrete.

When it comes to smoothing uneven sidewalk panels, our method goes beyond just fixing obvious hazards. We can address general unevenness that makes sidewalks uncomfortable to walk on, improving the overall experience for pedestrians while extending the life of your concrete.

Achieving ADA compliance is where our technology really shines. The Americans with Disabilities Act sets strict standards for public walkways, and our cutting method consistently exceeds these requirements. This helps municipalities, property managers, and HOAs meet their legal obligations while creating truly accessible spaces for everyone.

Most importantly, we’re preparing sidewalks for safe pedestrian use in communities across Florida. Every job we complete creates smoother, safer pathways that reduce accident risk and improve quality of life. It’s about building infrastructure that serves everyone, from parents pushing strollers to seniors using mobility aids.

Our focus remains laser-sharp on delivering effective, long-lasting solutions that address the root cause of sidewalk problems, ensuring safety and compliance without cutting corners.

Key Considerations and Limitations of Traditional Grinding Methods

When property managers first consider concrete grinding solutions for sidewalk trip hazards, traditional grinding methods might seem like the obvious choice. After all, they’ve been around for decades, and the concept sounds simple enough: just grind down the raised concrete until it’s level. Unfortunately, the reality is far more complicated and problematic than it appears on the surface.

The most immediate problem you’ll encounter is the dust creation. We’re not talking about a little concrete dust here and there. As one industry professional colorfully described it, “in about 3 minutes, there is such a thick cloud of concrete dust in the air, you can’t see the floor 24″ away!!!” This creates serious health concerns for workers and anyone passing by, while also disrupting nearby businesses and residents.

Then there’s the noise pollution factor. Traditional grinders are notoriously loud, creating an uncomfortable environment that can last for hours. But perhaps most frustrating of all is what happens when the dust settles and you actually examine the results.

Traditional grinding methods have a fundamental flaw: they simply cannot reach the edges of sidewalk panels effectively. This means that even after all the noise, dust, and disruption, the trip hazard often remains partially intact along the edges. You’re left with unsightly patches and the potential for new unevenness where the grinding stopped short of creating a proper transition.

To manage project budgets effectively, it’s wise to look for savings in all areas, not just repairs. Comparing rates on major expenses can free up funds for property maintenance, allowing for more effective solutions like precision cutting methods. For more detailed information about the specific challenges of grinding for sidewalk repairs, visit our page on sidewalk trip hazard repair.

The Challenge of ADA Compliance with Traditional Methods

Here’s where traditional concrete grinding solutions really fall short: meeting the strict requirements of ADA compliance. The Americans with Disabilities Act establishes a clear 1/4-inch rule – any vertical change of 1/4 inch or more at joints or cracks constitutes a trip hazard that must be addressed.

The problem is that traditional grinding methods produce inconsistent results. One area might be ground down properly, while another section remains slightly liftd. Without the precision needed to create uniform surfaces, you’re playing a dangerous game of “close enough” with legal compliance.

The edge limitations we mentioned earlier become even more critical when considering ADA standards. Even if the center portion of a trip hazard is ground down adequately, those unreachable edges can still exceed the 1/4-inch threshold. This creates ongoing liability concerns because your sidewalk technically still contains ADA violations, despite the time and money invested in repairs.

Property owners and municipalities who rely on traditional grinding often find themselves in a frustrating cycle: they think they’ve solved the problem, only to find they’re still exposed to potential lawsuits from trip-and-fall accidents. For a comprehensive understanding of ADA requirements, check out our detailed guide on ADA compliance.

Maintenance and Durability of Ground Surfaces

Even when traditional grinding manages to address the immediate trip hazard, it often creates new long-term problems that aren’t immediately obvious. The aggressive grinding process increases surface porosity in the concrete, essentially making it more porous and vulnerable to damage.

This increased porosity leads to potential for faster wear from regular foot traffic and weather exposure. The ground surface becomes more susceptible to cracking, staining, and general deterioration. Many property managers find they need frequent sealing treatments to protect the newly porous surface, adding unexpected costs to their maintenance budgets.

Unlike polished concrete floors where grinding is followed by densification and sealing processes, sidewalk grinding typically stops at the rough grinding stage. This leaves you with a surface that may look acceptable initially but struggles with long-term appearance and durability.

The result is often a repair that needs to be redone sooner than expected, turning what seemed like a cost-effective solution into an expensive cycle of repeated maintenance. When you factor in the ongoing costs and the persistent ADA compliance issues, traditional grinding becomes far less attractive than it initially appears.

Why Florida Sidewalk Solutions’ Cutting Method is the Best Concrete Grinding Solution

When you’re looking for concrete grinding solutions that actually work, you need to understand why our precision cutting method delivers results that traditional grinding simply can’t match. We’ve revolutionized sidewalk trip hazard repair with modern technology that goes far beyond what conventional methods can achieve.

The difference is immediately visible when you see our work. Instead of the rough, incomplete repairs typical of traditional grinding, our precision removal creates a smooth transition that looks natural and performs flawlessly. We’re not just grinding down a bump and hoping for the best – we’re surgically removing the exact portion of concrete that creates the hazard, leaving behind a perfectly level surface.

Here’s how our method compares to traditional approaches:

| Criteria | Traditional Grinding | Florida Sidewalk Solutions’ Cutting Method |

|---|---|---|

| Precision | Inconsistent, often leaves slight unevenness | Clean, tapered finish; perfectly level |

| Edge Work | Unable to reach edges; hazards often remain | Reaches all edges; seamless integration |

| ADA Compliance | Often fails to meet 1/4-inch rule; liability remains | Exceeds ADA standards; eliminates liability |

| Cleanliness | Creates significant dust cloud and debris | Dust-free process; minimal cleanup |

This comparison tells the whole story. While traditional concrete grinding solutions struggle with basic requirements, our method excels in every category that matters for sidewalk safety. You can learn more about why concrete cutting is the best sidewalk repair method on our detailed comparison page.

The Precision Advantage of Florida Sidewalk Solutions

Our patented technology is what sets us apart from every other sidewalk repair method. Think of it like the difference between using a scalpel versus a sledgehammer – both might get the job done, but only one delivers the precision you actually need.

The clean, tapered finish we achieve isn’t just about looks (though it does look great). This precision is crucial for creating a surface that meets ADA standards and stays compliant over time. Traditional grinding creates rough, uneven surfaces that can actually become trip hazards themselves as they wear down.

Most importantly, our method reaches all edges of the concrete panel. This might sound like a small detail, but it’s actually huge. When traditional grinders can’t reach the edges, they leave behind the very hazards they were supposed to eliminate. It’s like painting a room but leaving the corners untouched – the job simply isn’t complete.

Our process causes minimal disruption to foot traffic and creates no dust clouds that obscure vision or create health concerns. This means pedestrians can safely walk nearby while we work, and local businesses don’t have to deal with concrete dust settling on their storefronts. Learn more about our innovative approach on our patented sidewalk cutting technology page.

Achieving Flawless ADA Compliance with a Better Method

When it comes to ADA compliance, “close enough” isn’t good enough. The law is clear about that 1/4-inch rule, and our precision cutting method is specifically designed to exceed ADA standards every single time.

Traditional concrete grinding solutions often leave you in a gray area where the repair looks better but still doesn’t fully meet compliance requirements. This creates ongoing liability concerns that can cost far more than the original repair. With our method, you eliminate liability completely because the hazard is completely gone.

We also provide detailed GIS reporting that documents exactly what was repaired and confirms ADA compliance. This isn’t just paperwork – it’s your protection against future liability claims. When every repair is thoroughly documented and guaranteed to meet federal standards, you can rest easy knowing your sidewalks are truly safe for pedestrians.

The peace of mind that comes with knowing your sidewalk repairs exceed ADA requirements is invaluable. You can explore more about how we help you meet these critical standards at removing trip hazards for ADA compliance.

Cost-Effective Concrete Grinding Solutions Through Precision Cutting

Here’s where our method really shines: it delivers superior results while costing significantly less than alternatives. Our precision cutting costs just a fraction of replacement cost – typically about 1/10th the price of removing and replacing concrete panels.

But it gets even better. Our method is actually less expensive than traditional grinding when you factor in the complete repair and long-term value. While grinding might seem cheaper upfront, the incomplete repairs often require additional work or lead to ongoing liability issues that cost far more in the long run.

By completely eliminating trip hazards and ensuring ADA compliance, we help you prevent costly litigation from trip-and-fall accidents. Some of our clients have even seen reductions of 10% to 15% on their general liability insurance premiums after completing comprehensive sidewalk repairs with our method.

When you consider the avoided legal fees, reduced insurance costs, and the fact that our repairs last longer without needing touch-ups, our precision cutting offers exceptional long-term value. It’s not just about fixing today’s problem – it’s about preventing tomorrow’s headaches.

Frequently Asked Questions about Sidewalk Repair Solutions

We get lots of questions from property managers, municipalities, and HOAs about sidewalk safety and repair options. Here are the answers to the most common questions we hear:

What is considered a trip hazard by the ADA?

The Americans with Disabilities Act is very specific about this: any vertical change of 1/4 inch or more at joints or cracks is considered a trip hazard. That might not sound like much – it’s about the thickness of a nickel – but it’s enough to cause serious falls, especially for elderly pedestrians or people with mobility challenges.

This 1/4-inch rule isn’t just a suggestion; it’s a legal standard that carries real liability. When someone trips and falls on your property because of a sidewalk hazard, you could face costly lawsuits. The ADA definition covers both joints between concrete panels and cracks within panels, so even small damage can create big problems.

The importance of compliance goes beyond just avoiding legal trouble. Creating truly accessible walkways helps everyone in your community move around safely and confidently. For more details about identifying and addressing these hazards, check out our comprehensive guide on trip hazard repair.

Is Florida Sidewalk Solutions’ cutting method better than traditional grinding for sidewalks?

Yes, absolutely – and here’s why our precision cutting approach beats traditional concrete grinding solutions every time.

Precision is where we really shine. While grinding often leaves subtle bumps and inconsistencies, our patented cutting method creates a perfectly smooth, tapered finish. It’s like the difference between using a fine scalpel versus a rough file – the results speak for themselves.

Edge-to-edge repair is another game-changer. Traditional grinders simply can’t reach the edges of concrete panels, which means the trip hazard often remains right where people step. Our equipment eliminates the entire hazard, from edge to edge, leaving no dangerous spots behind.

The cleaner process makes a huge difference too. While grinding creates massive dust clouds that you literally can’t see through, our method is virtually dust-free. No more disrupting businesses or coating cars with concrete dust.

Superior long-term value comes from doing the job right the first time. Because we achieve flawless ADA compliance and eliminate the entire hazard, you won’t need expensive re-work down the road. Plus, the safety improvement is dramatic – our smooth, clean results create truly safe surfaces for everyone.

Who benefits from trip hazard removal services?

Nearly everyone responsible for concrete walkways can benefit from professional trip hazard removal, but we work most often with specific types of clients.

Property managers love our service because it eliminates liability headaches while keeping tenants and visitors safe. Instead of worrying about potential lawsuits, they can focus on other aspects of property maintenance.

Municipalities rely on us to keep public sidewalks safe and ADA-compliant. City officials appreciate that our method costs a fraction of full replacement while delivering better results than traditional grinding.

Homeowner Associations (HOAs) use our services to protect residents and maintain property values. Nothing brings down a neighborhood’s appeal like dangerous, uneven walkways.

School districts prioritize student safety, and our precision cutting ensures safe routes for kids, parents, and staff around school grounds.

Commercial property owners know that customer safety directly impacts their business. A slip-and-fall accident can damage both reputation and finances, making trip hazard removal a smart investment.

The common thread is simple: if you’re responsible for sidewalks or walkways, professional trip hazard removal protects both people and your bottom line.

Conclusion: Making the Right Choice for Your Sidewalks

When you’re walking down a sidewalk, the last thing you should worry about is tripping over uneven concrete. Yet sidewalk trip hazards pose real dangers every day, leading to painful falls, serious injuries, and expensive lawsuits that can devastate budgets and reputations.

Traditional concrete grinding solutions might seem like the obvious answer, but as we’ve explored throughout this guide, they come with significant drawbacks. The dust clouds that obscure vision, the inability to reach critical edges, and the inconsistent results that often fail ADA compliance standards all point to one conclusion: there’s got to be a better way.

And there is.

Our precision cutting method represents a fundamental shift in how sidewalk safety should be approached. Instead of accepting the limitations of conventional grinding, we’ve developed patented technology that delivers what property managers, municipalities, and HOAs actually need: complete trip hazard removal that exceeds ADA standards while costing a fraction of full replacement.

Think about it this way – when you choose our cutting method, you’re not just fixing today’s problem. You’re preventing tomorrow’s liability, ensuring genuine safety for every pedestrian, and creating smooth pathways that improve your community’s accessibility and appeal.

The choice really comes down to this: settle for partial fixes that leave you exposed to ongoing risks, or invest in a solution that gets it right the first time. Our expert service combines cutting-edge engineering with the kind of craftsmanship that delivers consistent, reliable results you can count on.

Your sidewalks deserve better than compromise solutions. Make the smart choice for lasting safety and compliance. Learn more about our ADA-compliant sidewalk solutions and find how we can transform your walkways into the safe, accessible pathways your community deserves.