Why Professional Cement Crack Repair Matters for Public Safety

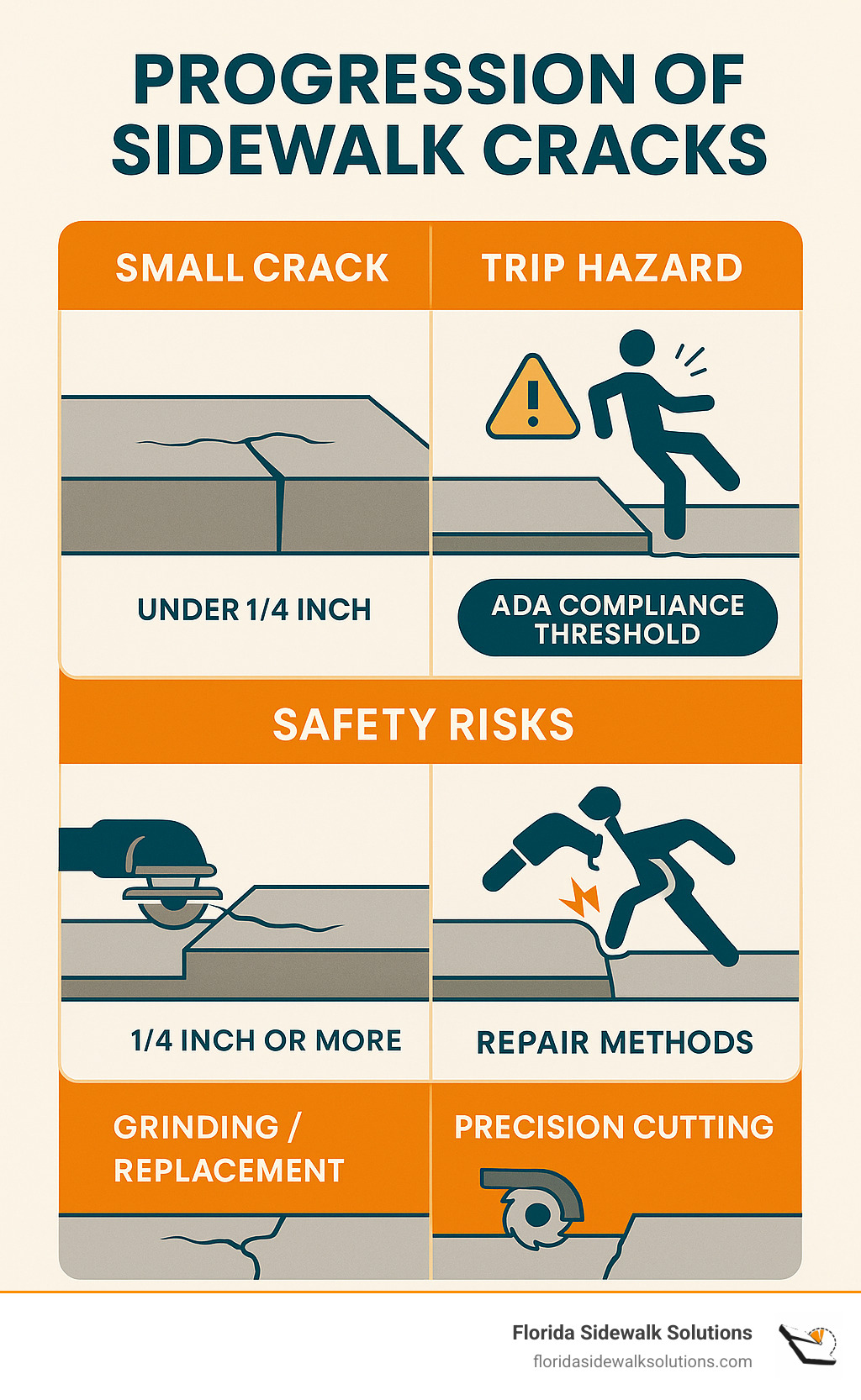

Cement crack repair becomes critical when sidewalk damage creates dangerous trip hazards and ADA compliance violations. As a municipal maintenance manager, you know that what starts as a simple crack can quickly escalate into costly liability issues and safety concerns for your community.

Quick Solutions for Cement Crack Repair:

- Small cracks (under 1/4 inch): Monitor for changes, may only need cosmetic filling

- Uneven slabs (1/4 inch height difference or more): Require immediate professional repair for ADA compliance

- Wide or structural cracks: Need expert assessment and precision cutting technology

- Trip hazards: Best solved with concrete leveling, not temporary patches or grinding

Cracked sidewalks aren’t just unsightly – they represent serious safety hazards that can lead to trip and fall accidents. The Americans with Disabilities Act defines any vertical change of 1/4 inch or more at a joint or crack as a “trip hazard,” making professional repair essential for legal compliance.

Traditional approaches like concrete grinding, scabbling, or full replacement are often costly, disruptive, and unnecessary. Modern precision concrete cutting technology offers a more effective solution that restores level surfaces, eliminates trip hazards, and meets ADA standards with minimal mess and disruption.

The key is understanding when a crack needs professional attention versus simple monitoring. Hairline cracks may only require cosmetic treatment, but any unevenness that creates a walking hazard demands immediate action to protect public safety and avoid costly litigation.

Cement crack repair terms to remember:

Understanding Sidewalk Cracks: Causes and Dangers

When it comes to cement crack repair for sidewalks, understanding why cracks happen is your first step toward preventing costly liability issues. Here’s the truth: concrete is incredibly strong, but it’s also brittle. Think of it like a really tough cookie – it can handle a lot of weight, but it doesn’t bend well. And just like that cookie, when stress builds up, something’s got to give.

Common Causes of Sidewalk Cracks

Freeze-thaw cycles are particularly brutal on concrete, even here in Florida during those rare cold snaps. When water seeps into tiny cracks and freezes, it expands by about 9% – imagine the pressure that puts on your sidewalk! It’s like having a tiny jackhammer working from the inside out.

Ground movement is another sneaky culprit. The soil under your sidewalk isn’t as stable as you might think. When it settles unevenly or shifts due to erosion, your concrete has to move with it. Since concrete doesn’t like to bend, it cracks instead.

Poor installation during the original construction can come back to haunt you years later. Maybe the concrete mix wasn’t quite right, or control joints weren’t placed properly. These issues don’t always show up immediately, but they create weak spots that eventually fail.

Tree roots are nature’s concrete movers. Those beautiful oak trees that provide such lovely shade? Their roots are incredibly strong and persistent. As they grow, they can lift entire sections of sidewalk, creating the kind of uneven surfaces that turn into serious trip hazards.

Water damage works slowly but surely. Poor drainage allows water to wash away the supporting soil beneath your sidewalk. Once that support is gone, the concrete settles and cracks, often creating the exact height differences that violate ADA standards.

For a deeper look at how these factors create concrete damage, check out our detailed guide on Concrete Cracks and Damage.

The Real Danger: Trip Hazards and Legal Liability

Here’s where things get serious. That little crack you’ve been ignoring? It might be costing you more than you realize.

The ADA compliance rules are crystal clear: any vertical height difference of 1/4 inch or more at a crack or joint creates a trip hazard. That’s not very much – about the thickness of six pennies stacked together. But this small measurement carries huge implications for property owners and municipalities.

Trip and fall liability is no joke. When someone gets hurt on your property because of an uneven sidewalk, you’re looking at potential medical bills, legal fees, and lawsuit settlements that can easily reach tens of thousands of dollars. We’ve seen property owners face serious financial hardship because they delayed addressing what seemed like minor sidewalk issues.

The legal liability for property owners extends beyond just the immediate costs of an accident. Your insurance rates can increase, your property value may decrease, and you might face ongoing legal scrutiny. Some of our clients have saved 10% to 15% on their general liability insurance simply by addressing trip hazards proactively.

But there’s another hidden danger: the 1/4-inch rule means that even small cracks can become major problems when water gets underneath and causes further settling. What starts as a hairline crack can quickly become a lawsuit-worthy trip hazard after just one heavy rain season.

Don’t let small problems become big headaches. Our page on Dangers of Neglecting Sidewalk Crack Repair shows you exactly what can happen when cement crack repair gets pushed to the bottom of your to-do list.

The good news? Modern precision cutting technology can address these hazards quickly and cost-effectively, without the mess and expense of traditional repair methods.

Assessing the Damage: Cosmetic Flaw or Major Hazard?

Here’s the truth about sidewalk cracks: they’re not all created equal. When you’re facing cement crack repair decisions, the key is knowing which cracks you can live with and which ones demand immediate action. Get this assessment wrong, and you could be looking at serious liability issues down the road.

Identifying Crack Types

Think of sidewalk cracks like medical symptoms – some are minor annoyances, while others signal serious problems that need immediate attention.

Hairline cracks are the least of your worries. These fine, shallow surface cracks often look like a spiderweb pattern across your concrete. They typically show up when concrete surfaces dry too quickly after pouring. While they might not win any beauty contests, they’re usually just cosmetic issues that don’t threaten anyone’s safety.

Shrinkage cracks appear as the concrete cures and naturally contracts. These through-thickness cracks often look relatively straight and predictable. They’re more noticeable than hairline cracks but don’t necessarily spell disaster if they remain level.

Structural cracks are where things get serious. These deep, wide cracks – often exceeding 1/4-inch in width – frequently come with uneven concrete slabs. When you see cracks bigger than an inch wide, especially in older sidewalks, you’re looking at signs of significant ground settlement, overloading, or severe weather damage.

Uneven cracks are your biggest concern for cement crack repair. These create a vertical displacement where one side sits higher than the other, forming a perfect tripping point. Critical ADA measurement: any vertical change of 1/4 inch or more transforms a simple crack into a legal liability.

When to Monitor

Not every crack requires an emergency response. You can take a “wait and see” approach when dealing with cracks under 1/4-inch wide that remain flush across both sides. These purely cosmetic issues might benefit from basic crack filler to prevent water intrusion and weed growth, but they don’t create immediate safety risks.

Hairline cracks without height differences often stay stable for years. You can monitor these for changes while focusing your repair budget on more pressing issues. However, keep in mind that even small cracks can worsen over time, especially when water repeatedly freezes and expands in them.

When to Call a Professional

This is where the rubber meets the concrete – literally. You need professional cement crack repair intervention when safety and compliance are at stake.

Uneven slabs creating trip hazards top the priority list. Any section with a vertical difference of 1/4 inch or more becomes an ADA violation and a lawsuit waiting to happen. This isn’t the time for DIY solutions or hoping the problem goes away. Our team specializes in Fixing Sidewalk Cracks Forming Trip Hazards using precision cutting technology that actually solves the problem.

Wide or deep cracks signal underlying issues that temporary fixes can’t address. While you might be tempted to fill deep cracks with oakum and masonry filler, these approaches often fail when the root cause involves ground movement or structural instability.

Signs of underlying structural problems demand expert assessment. When you notice uneven cracks exceeding an inch in width, stair-step patterns in adjacent walls, or general concrete instability, you’re dealing with foundation or subgrade issues that require professional diagnosis and repair.

The bottom line? When cracks threaten pedestrian safety or ADA compliance, professional intervention isn’t just smart – it’s essential for protecting both people and your liability exposure.

Why DIY Fillers and Grinding Fall Short for Trip Hazard Repair

We get it – when you spot a cracked sidewalk, the temptation to grab some filler from the hardware store and call it a day is strong. Maybe you’ve even considered renting a grinder to smooth things out. While these approaches might seem logical for general maintenance, they simply don’t cut it when you’re dealing with actual trip hazards that need ADA compliance.

Why Simple Fillers and Grinding Don’t Solve Trip Hazards

Here’s the thing about cement crack repair using basic fillers – they’re designed to fill gaps, not eliminate the height differences that create dangerous walking conditions. When one side of your sidewalk sits an inch higher than the other, squirting some caulk or epoxy into that crack doesn’t magically level the surface. You’ve just created a cosmetic bandage over a safety hazard.

They don’t level the concrete – and that’s the heart of the problem. The ADA’s 1/4-inch rule exists because even small height differences can send someone tumbling. A filler might hide the crack visually, but that dangerous lip is still there waiting to catch an unsuspecting foot.

Most DIY solutions end up being temporary cosmetic fixes at best. Rigid concrete patches often crack again due to natural expansion and contraction, especially here in Florida where temperature swings and occasional freeze-thaw cycles put stress on repairs. You might think you’ve solved the problem, only to find the same hazard reappearing months later.

Even worse, some approaches can worsen ADA compliance issues. Grinding might seem like it’s addressing the height difference, but it often creates sloped or uneven surfaces that still don’t meet accessibility standards. It’s like trying to level a lumpy cake by shaving off the high spots – you might reduce some bumps, but you haven’t created the smooth, consistent surface that wheelchairs, walkers, and pedestrians need.

Drawbacks of Traditional Approaches

Let’s talk about why the conventional methods property managers often consider fall short for sidewalk trip hazards specifically.

Concrete grinding involves using heavy machinery to wear down the higher slab, theoretically bringing it level with the lower section. While it costs less than full replacement, it creates more problems than it solves. The process rarely achieves a true level surface – instead, you get a ramped effect or feathered edge that can still trip people up. The ground concrete dust gets everywhere, creating a messy cleanup job and potential health concerns. Plus, you’re left with an obvious patch that looks completely different from the surrounding concrete.

Scabbling works similarly, using rotating heads to chip away concrete surfaces. Like grinding, it’s imprecise and leaves you with an aesthetically compromised sidewalk that may still not meet ADA requirements.

Full replacement certainly solves the problem, but it’s like using a sledgehammer to crack a nut. Professional cement crack repair through replacement can cost anywhere from hundreds to over a thousand dollars depending on the project scope, but you’re also dealing with days or weeks of disruption. Heavy machinery, noise, dust, and unusable walkways create headaches for everyone involved. The environmental impact of hauling away perfectly good concrete (except for one troublesome joint) doesn’t make much sense either.

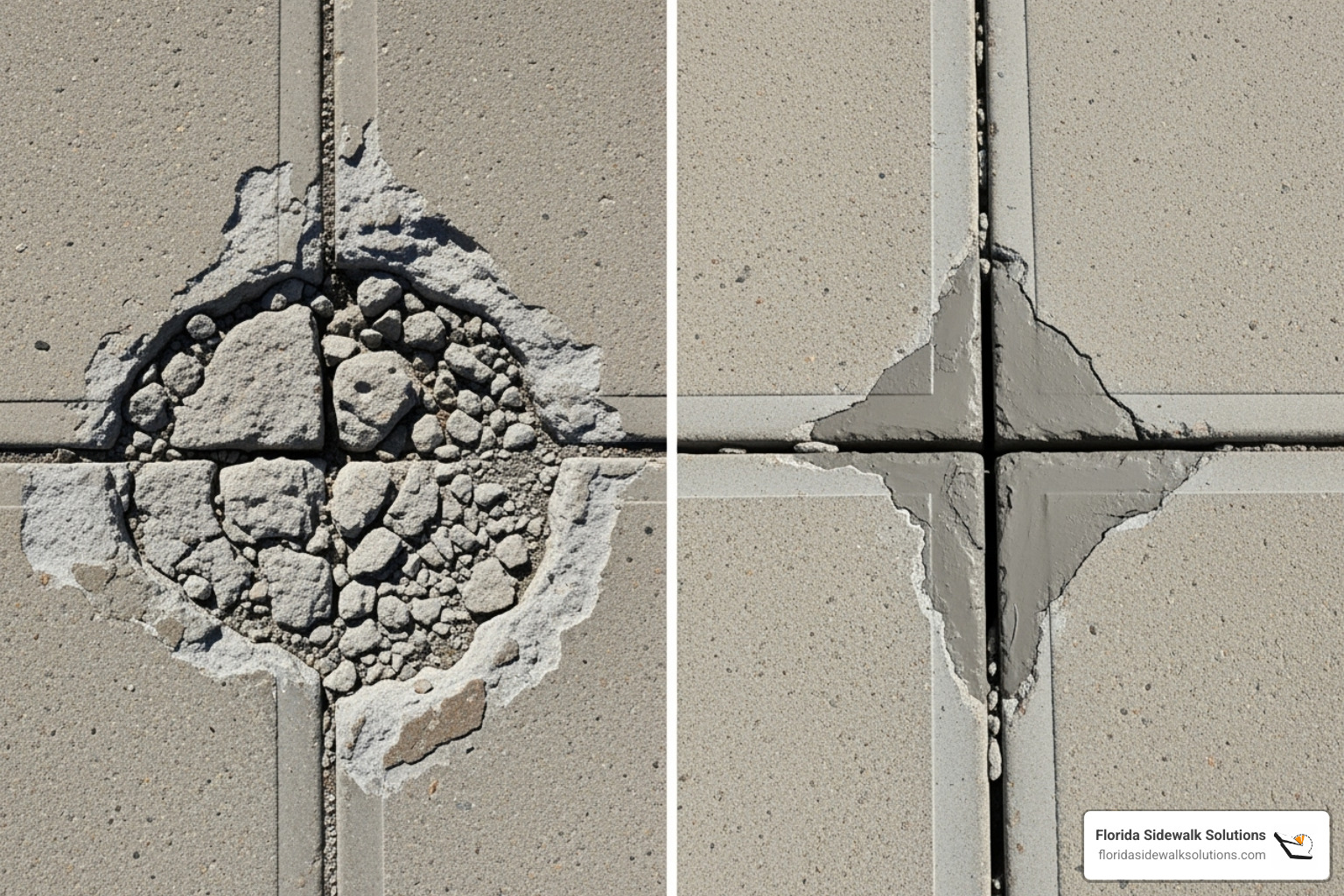

The reality is that most sidewalk trip hazards don’t require these dramatic, expensive interventions. What they need is a precise solution that actually levels the surface while maintaining the integrity and appearance of your existing concrete – which is exactly what our patented cutting technology delivers.

The Pro-Level Fix: Precision Concrete Cutting for Lasting, ADA-Compliant Results

We’ve explored why traditional DIY fillers and conventional grinding methods fall short when it comes to truly eliminating sidewalk trip hazards and achieving ADA compliance. Now, let’s talk about the professional solution that actually works: precision concrete cutting. This is where cement crack repair transforms from a temporary band-aid to a permanent, safe, and clean fix.

How Precision Cutting Works

Think of it this way: instead of trying to build up the low side or messily grind down the high side, we use specialized equipment to create a precise, engineered transition between uneven concrete slabs. It’s like having a master carpenter level your floor, but for concrete.

Our patented method restores a level surface by creating a smooth, flush transition exactly where it’s needed. No more ugly ramps, no more rough patches that catch your shoe. The result is a sidewalk that looks and feels natural.

Most importantly, this approach eliminates trip hazards completely. We’re not just reducing the height difference – we’re creating a seamless pathway that’s safe for everyone, from joggers to wheelchair users to parents pushing strollers.

The precision cutting meets ADA standards with surgical accuracy. Critical 1/4-inch rule? Our method ensures your sidewalk not only meets but exceeds these requirements, giving you complete peace of mind about compliance.

And here’s the best part: there’s minimal mess and disruption. While other methods leave you with dust clouds, debris piles, and weeks of construction chaos, our process is remarkably clean and efficient. Your sidewalk is back in service almost immediately.

The Florida Sidewalk Solutions Advantage

We didn’t just stumble onto this technology – we developed it specifically to solve the problems that other methods couldn’t handle. This patented method is uniquely ours, and it’s what sets us apart in the concrete repair industry.

The financial benefits are significant. Our approach is cost-effective because we repair only what needs fixing, avoiding the massive expense of tearing out and replacing entire sections of concrete. Why pay for a complete sidewalk replacement when precise cutting can solve your trip hazard problem for a fraction of the cost?

Time matters, especially when you’re managing public walkways or commercial properties. Our method is fast – what might take weeks with traditional approaches often takes just hours with our precision cutting technology. Less downtime means less inconvenience for everyone.

Unlike temporary fixes that fail after a few freeze-thaw cycles, our solution is permanent. We address the trip hazard directly and definitively, so you won’t be dealing with the same problem again next year.

For detailed information about how our specialized approach can transform your problematic sidewalks, visit our Sidewalk Crack Repair Service page.

The difference becomes crystal clear when you compare the options side by side:

| Feature | Precision Concrete Cutting (Our Method) | Conventional Grinding | Full Concrete Replacement |

|---|---|---|---|

| Cost | Most Economical | Moderate | Most Expensive |

| Time | Fast (Hours) | Fast (Hours) | Slow (Days to Weeks) |

| Mess | Minimal | Moderate (Dusty) | High (Debris, Noise) |

| ADA Compliance | Guaranteed & Precise | Often Compromised (Ramps/Slopes) | Yes (but overkill) |

| Longevity | Long-lasting, Permanent | Temporary (Problem may recur) | Permanent |

| Disruption | Very Low | Low to Moderate | High |

| Aesthetics | Clean, Blends Seamlessly | Visible Patch, Different Texture | New, but often stands out |

When you’re dealing with sidewalk trip hazards, precision concrete cutting consistently outperforms traditional approaches across every metric that matters for effective cement crack repair.

Frequently Asked Questions

We get a lot of questions from property managers and community leaders about cement crack repair and sidewalk safety. These conversations often reveal the same concerns and misconceptions, so let’s tackle the most common ones head-on.

Why is professional cement crack repair essential for ADA compliance?

Here’s the thing about ADA compliance – it’s not just a suggestion or a nice-to-have. It’s the law, and for good reason.

The Americans with Disabilities Act defines any vertical change of 1/4 inch or more as a trip hazard. That quarter-inch might seem tiny, but it’s a huge deal for someone using a wheelchair, walker, or cane. It’s also dangerous for anyone with visual impairments or balance issues – basically, all of us at some point in our lives.

Professional repair isn’t just about meeting legal requirements – though avoiding costly lawsuits is certainly important. It’s about creating genuinely safe spaces. When someone trips and falls on your property because of an uneven sidewalk, you’re looking at potential medical expenses, legal fees, and damage to your reputation. Many property owners actually see their general liability insurance costs drop after they proactively address trip hazards.

The precision of professional methods makes all the difference. You simply can’t achieve true ADA compliance with DIY patches or basic grinding. Our patented cutting method ensures the repaired area is perfectly flush, completely eliminating that dangerous 1/4-inch threshold. It’s like the difference between using a butter knife and a surgeon’s scalpel – both might cut, but only one gives you the precision you actually need. For more details on what professional expertise brings to the table, check out our Sidewalk Crack Repair Company page.

How much does it cost to fix a cracked sidewalk trip hazard?

This is probably the question we hear most often, and honestly, it’s like asking “how much does a car cost?” The answer depends on what you’re actually buying.

Several factors influence the final cost of cement crack repair. The repair method you choose makes the biggest difference – our precision cutting is significantly more economical than tearing out and replacing entire sections. The severity of damage matters too; a small isolated trip hazard costs much less than extensive uneven areas. We typically price based on linear feet of repair needed.

Professional repair costs generally range from $100 to $1,000 or more, depending on the size and complexity of the job. That might sound like a wide range, but here’s the key: our specialized focus on trip hazards allows for targeted, efficient solutions rather than broad, expensive fixes.

Precision cutting delivers way more value than replacement. Think about it – why would you demolish and rebuild an entire sidewalk section when you can precisely level just the problem area? Full replacement involves breaking up concrete, hauling away debris, pouring new concrete, and waiting for it to cure. That’s expensive, disruptive, and often unnecessary. Our method focuses only on eliminating the hazard, saving you money on labor, materials, and downtime. We’re more effective and less expensive than conventional approaches, making it the smartest long-term investment for safety and compliance.

How can I prevent sidewalk trip hazards from forming?

While you can’t prevent every crack (concrete is practically guaranteed to crack eventually), you can definitely reduce your cement crack repair needs with some smart prevention strategies.

Proper installation with control joints is your first line of defense. These are intentional weak spots that guide cracks into straight, manageable lines rather than random patterns that create unevenness. Think of them as the concrete equivalent of perforated paper – they control where the “tear” happens.

Water management is absolutely critical. Water is concrete’s biggest enemy, causing ground movement and subgrade erosion. Make sure you have effective drainage systems that prevent water from pooling and seeping under your slabs. This includes proper grading of landscaping areas.

Regular monitoring catches problems early. Conduct annual safety surveys of your sidewalks, especially near trees or in areas prone to settlement. Spotting subtle shifts or hairline cracks early lets you take preventative action before they become major trip hazards.

Smart tree management helps too. Choose tree species with less aggressive root systems when planting near sidewalks. For existing problematic trees, consider root barriers or professional root pruning rather than waiting for severe damage.

Taking these steps significantly extends your sidewalks’ lifespan and reduces future repair costs. For additional maintenance tips, visit our resources on how to Repair Sidewalk Crack.

Conclusion: The Smartest Path to a Safer, ADA-Compliant Sidewalk

Throughout this guide, we’ve walked you through the essential aspects of cement crack repair for sidewalk trip hazards – and honestly, it’s a topic that’s close to our hearts here at Florida Sidewalk Solutions. We see how a simple crack can transform from a minor eyesore into a serious safety concern that keeps property managers awake at night.

The truth is, not every crack needs immediate professional attention. Those hairline surface cracks? They’re often just cosmetic and can be monitored over time. But when you’re dealing with uneven slabs that create a 1/4-inch height difference or more, that’s when the situation becomes urgent. These aren’t just unsightly – they’re genuine trip hazards that put your community at risk and expose you to significant legal liability.

We’ve seen too many property owners try the “quick fix” route with DIY fillers or conventional grinding, only to find these methods don’t actually solve the underlying problem. Grinding might reduce the height difference, but it often leaves you with a ramped surface that still doesn’t meet ADA standards. And simple fillers? They’re like putting a band-aid on a broken bone – they might cover the problem, but they don’t eliminate the danger.

Full concrete replacement might seem like the ultimate solution, but it’s often like using a sledgehammer to crack a nut. Yes, it works, but at what cost? The expense, disruption, and time involved make it unnecessary for most trip hazard situations.

This is exactly why we developed our patented precision cutting technology. Our method doesn’t just mask the problem or create a temporary fix – it precisely levels the concrete to eliminate trip hazards completely. The result is a permanent, ADA-compliant solution that’s faster, cleaner, and more cost-effective than traditional approaches.

When you choose modern cutting technology over conventional methods, you’re choosing safety, compliance, and peace of mind. Our approach protects your community members from dangerous falls while protecting your organization from costly litigation and insurance claims.

At Florida Sidewalk Solutions, we’ve made it our mission to keep Florida’s sidewalks safe and accessible. Whether you’re managing properties in Davie, Fort Lauderdale, Coral Springs, Boca Raton, West Palm Beach, Miami, or Fort Myers, we understand the unique challenges our climate and environment present to concrete surfaces.

Ready to transform your problematic sidewalks into safe, compliant walkways? Contact our concrete walkway repair company for a free estimate and find how our innovative approach to cement crack repair can solve your trip hazard challenges once and for all. We’re here to help you create sidewalks that everyone can use safely and confidently.