Navigating the Bumps: Why ADA Trip Hazard Repair Matters

ADA Trip Hazard Repair refers to the process of fixing uneven sidewalk surfaces to comply with Americans with Disabilities Act standards. If you’re looking for a quick answer about what constitutes a trip hazard and how to address it:

ADA Trip Hazard Quick Guide:

– Definition: Any vertical change over 1/4 inch at a joint or crack

– Legal requirement: Must be repaired to avoid liability and fines

– Repair options: Cutting, grinding, or replacement (cutting is often most cost-effective)

– Potential fines: Up to $75,000 for first violations, $150,000 for subsequent violations

Did you know that even a seemingly minor sidewalk imperfection can create significant legal liability? According to ADA standards, a vertical change of just over 1/4 inch on a sidewalk surface is classified as a trip hazard. These small imperfections might not catch your eye during a routine inspection, but they represent serious safety risks and compliance issues.

For municipal maintenance managers, addressing these hazards isn’t just about avoiding lawsuits—it’s about creating accessible public spaces for everyone. The good news is that modern repair methods can fix these issues quickly and cost-effectively without complete sidewalk replacement.

As Nicholas R. Jones, P.E., a city engineer, noted: “Seldom do cities receive compliments on construction activities, but with Precision Concrete Cutting we have received numerous compliments from citizens and their satisfaction with the work that has been accomplished.”

Repairing trip hazards is significantly more economical than complete removal and replacement. While full sidewalk replacement can cost upwards of $10,000, targeted repairs can address 15-20 trip hazards in a single day at a fraction of that cost.

Understanding ADA Trip Hazards

What Exactly Constitutes an ADA Trip Hazard?

When you’re out for a stroll, you might not notice that tiny lip in the sidewalk—but for someone using a wheelchair, it could be the difference between a smooth journey and a dangerous obstacle.

According to the Americans with Disabilities Act (ADA), a trip hazard is officially defined as any vertical change over 1/4 inch at any joint or crack in a walkway surface. For changes between 1/4 and 1/2 inch, the rules require a beveled edge with a maximum slope of 1:2 to create a safer transition.

That quarter-inch threshold isn’t arbitrary. It represents the point at which someone using a mobility device might struggle to steer safely. For wheelchair users, even small elevation changes can cause chairs to tip. For those using walkers or canes, these small “bumps” can lead to painful falls. And for people with visual impairments, unexpected changes in sidewalk height often go undetected until it’s too late.

The Legal Framework and Compliance Requirements

The ADA became law in 1990, creating a landmark shift in how we think about accessibility in public spaces. For sidewalk maintenance, two sections are particularly important:

Title II applies to state and local governments, requiring accessible public walkways.

Title III extends to businesses and commercial facilities, mandating that customer pathways remain safe and accessible.

These aren’t just guidelines—they’re federal requirements with teeth. Non-compliance can lead to:

- First violation fines up to $75,000

- Subsequent violation fines up to $150,000

- Costly personal injury lawsuits

- Legal expenses and settlements

- Reputation damage that’s hard to repair

Many property managers are surprised to learn they’re responsible for maintaining these standards, but the guidelines for ADA standards are clear about where liability falls.

The Practical Impact of Trip Hazards

Beyond legal concerns, there’s a very human reason to care about ADA Trip Hazard Repair. The National Safety Council reports that falls remain one of the leading causes of nonfatal injuries in 2025, with many occurring on uneven public walkways.

Each one of these statistics represents a real person who experienced pain, medical bills, and potentially life-changing injuries—all from something as seemingly minor as an uneven sidewalk.

For municipalities and business owners, addressing these hazards isn’t just about avoiding lawsuits (though that’s important too). It’s about creating communities where everyone can steer safely, regardless of age or ability. It’s about recognizing that public spaces should truly be accessible to all members of the public.

When we repair trip hazards, we’re not just fixing concrete—we’re building more inclusive communities, one quarter-inch at a time.

Common Causes of Trip Hazards on Sidewalks

Understanding what causes trip hazards is essential for both prevention and effective repair. Several factors contribute to the development of uneven sidewalk surfaces:

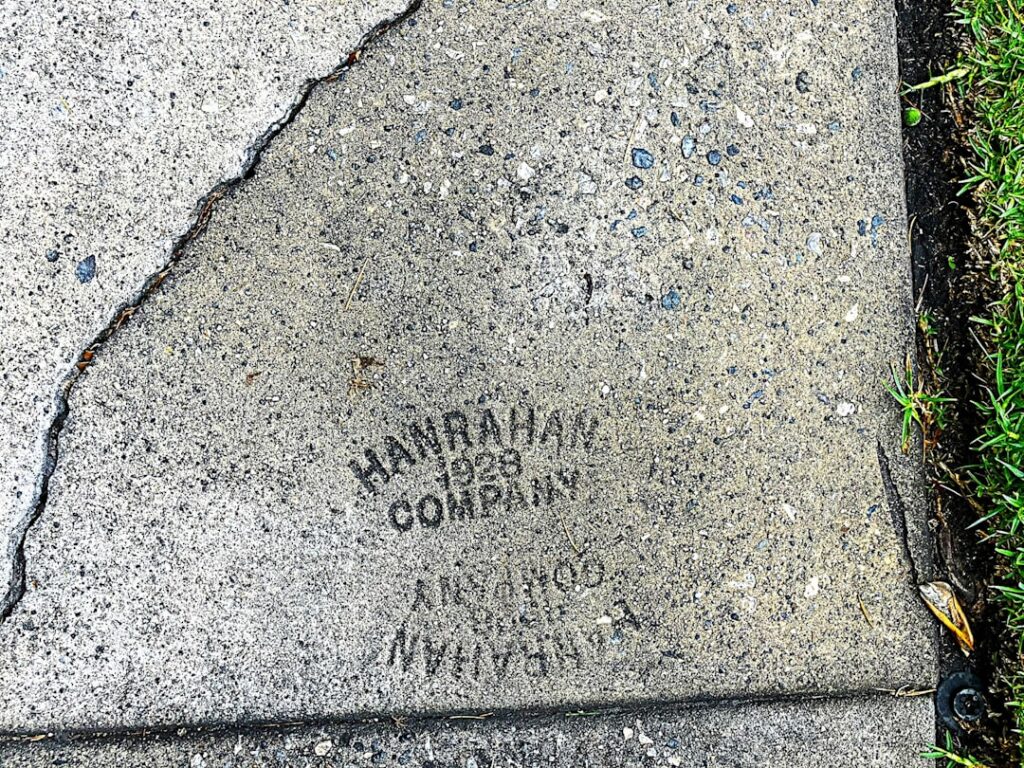

Tree Root Intrusion

One of the most common causes of sidewalk damage is tree root growth. As trees mature, their root systems expand outward and upward, often lifting concrete slabs and creating significant vertical displacements. This is particularly prevalent in areas with large shade trees planted near walkways.

The challenge with tree root damage is that simply repairing the concrete doesn’t address the underlying issue. Without proper root management, the problem will likely recur. That’s why comprehensive ADA Trip Hazard Repair often includes strategies for managing root systems while preserving the health of valuable trees.

Here in Florida, we’ve seen countless beautiful oak trees whose roots have created sidewalk hazards throughout neighborhoods in Miami, Fort Lauderdale, and Tampa. The good news? These issues can be addressed without sacrificing either safety or our treasured tree canopy.

Ground Shifting and Settlement

Natural soil movement can cause concrete slabs to shift, creating uneven surfaces. Florida’s sandy soil is particularly prone to settlement, especially after heavy rains or periods of drought when the ground contracts.

You might notice this happening in areas with expansive clay soils that swell when wet and shrink when dry, regions vulnerable to erosion, or locations where the soil wasn’t properly compacted during initial construction. When the ground beneath a sidewalk settles unevenly, sections of the walkway can sink or tilt, creating trip hazards at the joints where they meet adjacent slabs.

Freeze-Thaw Cycles

While less common in sunny South Florida, many northern parts of the country experience significant damage from freeze-thaw cycles. Water seeps into small cracks in concrete, then expands when frozen, widening those cracks. With each cycle, the damage worsens, eventually leading to significant displacement between adjacent slabs.

Even in Florida, our occasional cold snaps can contribute to this problem in some northern parts of the state.

Poor Initial Construction

Sometimes the problem begins before the first pedestrian ever walks on a sidewalk. Inadequate base preparation, improper concrete mixing, insufficient control joints, or poor finishing techniques can all lead to premature cracking and uneven settlement.

We’ve seen countless examples where cutting corners during installation led to expensive repairs just a few years later. Proper installation with appropriate materials and techniques can dramatically extend the life of your sidewalks.

Normal Wear and Tear

Even well-constructed sidewalks deteriorate over time. Constant foot traffic, exposure to Florida’s intense sun and frequent rainstorms, and the natural aging of materials all contribute to the gradual development of trip hazards. This is simply part of owning or managing property with concrete walkways.

Environmental Factors

Our unique Florida environment brings its own challenges to sidewalk maintenance. Heavy rains can cause excessive moisture and poor drainage, while our abundant vegetation can accelerate deterioration. Other environmental factors that commonly contribute to sidewalk damage include vehicle traffic on sidewalks not designed for heavy loads, extreme temperature fluctuations, and exposure to salt in coastal areas.

At Florida Sidewalk Solutions, we’ve addressed these issues throughout South Florida, from Miami to West Palm Beach and Fort Myers. Our experience has taught us that understanding the root cause (sometimes literally!) of a trip hazard is crucial for implementing the most effective and long-lasting repair solution.

Rather than simply grinding down the concrete or completely replacing sidewalk sections, our patented cutting technology allows us to precisely address the specific trip hazard while maintaining the structural integrity of the remaining sidewalk. This approach not only ensures ADA compliance but also provides a more cost-effective and less disruptive solution for property owners and municipalities.

Methods for ADA Trip Hazard Repair

When it comes to fixing uneven sidewalks, not all repair methods are created equal. Let’s explore your options for ADA Trip Hazard Repair and why some approaches deliver better results than others.

Concrete Grinding

Concrete grinding has been around for years as a quick fix for minor sidewalk issues. This method uses a floor grinder to wear down the higher portion of concrete until it’s more level with the adjacent surface.

While grinding seems straightforward, it comes with significant limitations. The process often leaves behind a rough, abrasive surface that doesn’t look great. More importantly, grinding typically can’t reach all the way to edges and corners where trip hazards often exist.

“What’s wrong with sidewalk grinding?” We hear this question often. The simple answer is that grinding frequently leaves behind partially fixed trip hazards, especially at the edges where people are most likely to catch their feet. For minor issues under 1/8 inch, grinding might work, but for true ADA Trip Hazard Repair, it falls short of delivering complete compliance.

Plus, without proper vacuum systems, traditional grinding creates clouds of concrete dust that can affect nearby businesses, pedestrians, and the environment.

Concrete Scarifying/Planing

A step up from basic grinding, scarifying (also called planing) uses rotating cutters with tungsten carbide tips to remove concrete surfaces more aggressively. This method can handle larger vertical displacements and creates a textured surface that provides better slip resistance.

Scarifying equipment typically costs around $400 per day to rent, and an experienced crew might complete 15-20 trip hazard repairs in a day. While more effective than basic grinding, scarifying still has drawbacks. The process is noisy, dusty, and often leaves visible marks that don’t blend well with the surrounding sidewalk.

The technique also requires skilled operators to avoid damaging the concrete beyond what’s necessary. Like grinding, scarifying struggles to reach edges effectively, leaving potential compliance issues unresolved.

The Florida Sidewalk Solutions Method for ADA Trip Hazard Repair

At Florida Sidewalk Solutions, we take a fundamentally different approach with our patented precision cutting technology. Rather than grinding down the surface, we make horizontal cuts through the raised concrete to create perfectly smooth, uniform transitions.

Our process begins with a detailed assessment of each trip hazard, measuring the exact vertical displacement. Then, using our specialized equipment, we make a precise horizontal cut through the raised section. This cut creates a smooth ramp with a gentle slope (1:12 or less) that fully complies with ADA requirements.

What makes our method superior? For starters, it completely eliminates the trip hazard from edge to edge – including those troublesome corners and areas along walls. The result looks clean and professional, blending seamlessly with the surrounding sidewalk without the rough, patchy appearance left by grinding or scarifying.

Our cutting approach also generates minimal dust and debris, making it ideal for busy commercial areas and public spaces. Perhaps most importantly, it addresses vertical displacements of any size while preserving the integrity of your sidewalk.

As one property management firm in Miami put it: “Florida Sidewalk Solutions will prove to you you can trust them, no question. They have the Trip Hazard market figured out in a simple way like no others. This is what we all want with contractors–trust.”

Our philosophy is simple: “Cut it – don’t grind it!” This approach not only ensures complete ADA Trip Hazard Repair, but it typically costs about 1/10th of what you’d pay for complete removal and replacement. That’s why municipalities, HOAs, and property managers throughout South Florida trust us to bring their sidewalks into compliance quickly and affordably.

When you’re facing trip hazard issues, the method you choose makes all the difference in achieving true compliance, aesthetic results, and long-term value.

Benefits of Timely ADA Trip Hazard Repair

Substantial Cost Savings Compared to Replacement

When it comes to sidewalk maintenance, your wallet will thank you for choosing targeted repairs over complete replacement. Full sidewalk removal and replacement isn’t just disruptive—it’s expensive, often costing upwards of $10,000 even for modest sections. Our precision cutting method at Florida Sidewalk Solutions typically costs about one-tenth of that amount, making it the smart choice for budget-conscious property managers and municipalities.

Let’s look at the numbers that make this decision so clear:

| Repair Method | Average Cost per Hazard | Time Required | Disruption Level | Appearance |

|---|---|---|---|---|

| Precision Cutting | $75-150 | 15-20 min | Minimal | Smooth, uniform |

| Grinding | $50-100 | 20-30 min | Moderate | Rough, uneven |

| Scarifying | $100-200 | 25-35 min | Moderate | Textured, visible |

| Full Replacement | $1,000-1,500 | 1-3 days | Significant | New concrete |

With our efficient ADA Trip Hazard Repair approach, we typically fix 15-20 trip hazards in a single day. This means you can address multiple problem areas quickly without breaking the bank or disrupting pedestrian traffic for days on end.

Liability Reduction and Risk Management

Those small sidewalk lips aren’t just accessibility issues—they’re lawsuits waiting to happen. Timely repairs significantly reduce your liability exposure. Trip and fall accidents on public sidewalks often lead to personal injury lawsuits, insurance claims, premium increases, and costly legal battles that can drag on for months or even years.

The insurance industry has taken notice too. In 2025, maintaining concrete levels in accordance with ADA standards can help save 10-15% on general liability insurance premiums. That’s real money back in your budget year after year, on top of avoiding potential lawsuit damages that could run into six figures.

As one property manager told us after completing repairs: “I sleep better at night knowing we’ve addressed these hazards. The peace of mind alone is worth the investment.”

Improved Safety for All Pedestrians

While ADA Trip Hazard Repair focuses on accessibility for individuals with disabilities, everyone benefits from smooth, even walking surfaces. Think about all the people who use your sidewalks daily:

Elderly neighbors out for their morning walks. Parents pushing strollers to the park. Kids learning to ride bikes. Joggers getting their exercise. Delivery drivers rushing to make their next stop. Anyone walking at dusk or after dark.

The National Safety Council’s 2025 data continues to show that falls remain a leading cause of nonfatal injuries. By fixing those uneven joints and cracks, you’re creating a safer community space for everyone who passes through.

Compliance with ADA Requirements

The financial penalties for non-compliance with ADA standards are serious business—up to $75,000 for first violations and a whopping $150,000 for subsequent violations. But that’s just the beginning.

Entities found in violation may also face comprehensive remediation plans, ongoing monitoring, plaintiffs’ legal fees, and public accommodations or settlements. The costs can quickly spiral.

By proactively addressing trip hazards, you demonstrate good faith efforts toward compliance. This proactive approach can significantly reduce your exposure if issues do arise, showing that you take accessibility seriously.

Improved Public Perception and Community Relations

Never underestimate the power of smooth sidewalks to generate goodwill. As Chris McGee, a Transportation Field Services Manager, observed: “The benefit is we have a reduced number of calls from the public complaining about issues with their sidewalks, so these groups of people are very excited for us to come in and use this process instead of ripping out 100 feet of sidewalk.”

When you prioritize ADA Trip Hazard Repair, you’re sending a clear message about your values. You’re showing commitment to public safety, responsible management of resources, attention to the needs of all community members, and a proactive approach to maintenance.

These repairs may seem small, but they make a big impression. Residents notice when their concerns are addressed promptly and effectively. That positive perception translates into stronger community relations and public trust—something every municipality and business needs but can’t buy at any price.

Ensuring Ongoing ADA Compliance for Sidewalks

Keeping sidewalks ADA-compliant isn’t something you do once and forget about. It’s more like tending a garden—regular care prevents small issues from becoming big problems. Let’s explore how to keep your walkways safe and accessible for everyone in your community.

Developing a Comprehensive Inspection Program

The key to staying on top of sidewalk compliance is having a regular inspection routine. Think of it as a health check-up for your concrete pathways.

Annual inspections should be your minimum standard, but high-traffic areas deserve more frequent attention. During these inspections, take detailed notes about what you find. Document the date, who performed the inspection, and exactly what issues you finded.

Photos are incredibly valuable here—they provide visual evidence of problems and help track changes over time. And don’t just eyeball those trip hazards! Use proper measurement tools like digital levels and depth gauges to accurately record vertical displacements.

Many of our more tech-savvy clients in South Florida have started using GIS mapping to track sidewalk conditions. This approach transforms scattered inspection notes into a visual map that helps prioritize repairs strategically.

As one city engineer we work with put it: “Using detailed GIS reporting for precise assessment and documentation of sidewalk conditions has transformed our maintenance program from reactive to proactive.”

Implementing Preventative Maintenance Strategies

An ounce of prevention truly is worth a pound of cure when it comes to sidewalk maintenance.

When planting trees near walkways, consider installing root barriers to guide growth downward rather than toward your sidewalks. Better yet, choose tree species with less invasive root systems in the first place. Those beautiful shade trees might look appealing now, but their roots can create major headaches down the road.

Water is concrete’s subtle enemy. Regularly sealing joints between sections prevents moisture infiltration that leads to freeze-thaw damage. Proper drainage away from sidewalks prevents soil erosion that can leave concrete slabs unsupported.

And when installing new sidewalks, don’t cut corners! Proper base preparation and quality concrete mix specifications pay dividends through extended sidewalk life and fewer repairs.

Prioritizing Repairs Based on Risk and Usage

When you can’t fix everything at once, smart prioritization becomes essential. Not all trip hazards are created equal.

Severity of the hazard should be your first consideration—larger vertical displacements generally present greater risks. But also think about pedestrian traffic volume. A moderate trip hazard in a busy area might need attention before a severe one in a rarely used location.

Pay special attention to walkways near hospitals, schools, senior centers, and public transit stops. These areas serve vulnerable populations and typically see higher foot traffic.

And always address locations where incidents have already occurred. A reported fall or complaint should trigger immediate inspection and repair.

Training Staff on ADA Requirements

Your maintenance team can’t fix what they don’t recognize as a problem. Regular training on ADA standards ensures everyone knows what to look for.

Create clear, written guidelines that help staff identify trip hazards correctly. Encourage everyone—not just maintenance personnel—to report potential problems. The landscaper who notices a slight sidewalk lift while mowing might spot an issue before it becomes a liability.

Establish clear accountability for addressing identified hazards within specific timeframes. Without deadlines, even well-documented problems can linger too long.

Throughout South Florida—from Fort Lauderdale to Miami and Boca Raton—we’ve helped municipalities develop training programs that empower staff to spot potential issues before they become serious hazards.

Tips for Municipalities and Businesses

Establishing Effective Inspection Schedules

For cities managing miles of sidewalks, breaking the task into manageable zones makes sense. Rotate through these zones on a consistent schedule to ensure complete coverage.

Consider your local climate when planning inspections. In areas with freeze-thaw cycles, schedule additional checks after winter. In rainy regions like South Florida, inspect more frequently during and after the wet season.

Make it easy for residents to help! User-friendly reporting systems—whether mobile apps or simple hotlines—multiply your inspection capabilities by engaging community members as extra eyes on the ground.

Prioritizing Repairs Effectively

With limited budgets, strategic repair planning is crucial. Consider developing a simple risk assessment matrix that weighs both the severity of each hazard and its location’s foot traffic.

For hazards that can’t be immediately fixed, temporary measures like high-visibility marking can reduce accident risk while permanent repairs are scheduled.

Whenever possible, group repairs by location to minimize travel time and setup costs. And schedule work during favorable weather conditions to ensure quality results with minimal disruption.

Engaging Qualified Professionals

When selecting a contractor for ADA Trip Hazard Repair, do your homework. Ask for references and examples of similar projects. Verify that they understand ADA requirements and carry appropriate licensing and insurance.

Pay close attention to their repair methods. Some contractors merely reduce trip hazards rather than fully eliminating them. The lowest bid rarely provides the best long-term value if repairs need frequent repetition.

At Florida Sidewalk Solutions, we’ve built our reputation as trusted partners for municipalities and businesses throughout South Florida. From Coral Springs to West Palm Beach, our patented cutting technology eliminates trip hazards completely—not just temporarily masks them.

Maintaining ADA-compliant sidewalks isn’t just about avoiding lawsuits. It’s about creating communities where everyone can move freely and safely, regardless of age or ability.

Frequently Asked Questions about ADA Trip Hazard Repair

What is considered a trip hazard under the ADA?

When you’re walking down a sidewalk, that little lip of concrete that catches your toe might seem minor—but in the eyes of the ADA, it’s a serious concern. ADA Trip Hazard Repair standards are quite specific: any vertical change over 1/4 inch at a joint or crack is officially considered a trip hazard. For changes between 1/4 and 1/2 inch, you’ll need a beveled edge with a slope no steeper than 1:2 to stay compliant.

These standards apply everywhere the public walks—from the sidewalks outside your city hall to the pathway leading to your business entrance. Whether the cause is tree roots pushing up concrete or natural settling over time, the requirement remains the same. The law doesn’t care why the hazard exists—just that it needs to be fixed.

Many property managers are surprised to learn how strict these standards are, but there’s good reason behind them. Even small changes in elevation can create major obstacles for people using mobility devices or those with visual impairments.

Why is it important to repair trip hazards promptly?

“We’ll get to it eventually” is a phrase we hear often—but when it comes to sidewalk trip hazards, delay can be costly in multiple ways.

First and foremost is safety. Falls aren’t just uncomfortable—they can be life-changing. The latest 2025 data from the National Safety Council confirms that falls remain one of the leading causes of nonfatal injuries, many occurring on uneven walking surfaces. Behind each statistic is a real person who might face painful recovery, medical bills, and lost work time.

The financial implications of ignoring trip hazards can be staggering. Those government-imposed fines—up to $75,000 for first violations and $150,000 for subsequent ones—often shock property owners who thought they could postpone repairs. And that doesn’t even include potential lawsuit settlements if someone is injured.

What many don’t realize is that small trip hazards rarely stay small. That 1/4-inch lip will likely be 1/2-inch next year as freeze-thaw cycles, tree roots, and natural settling continue their work. Early intervention is almost always more economical.

Perhaps most importantly, maintaining smooth walkways is about creating inclusive communities. As one of our clients, a property manager in Boca Raton, told us: “When we fixed our sidewalks, we weren’t just checking a compliance box—we were telling everyone in our community that they’re welcome here, regardless of mobility challenges.”

How does the Florida Sidewalk Solutions method differ from other repair methods?

Not all ADA Trip Hazard Repair methods are created equal. Our approach at Florida Sidewalk Solutions stands apart in ways that matter to both your budget and the final result.

Traditional grinding merely skims the surface, often leaving behind partial hazards and creating rough, obvious patches that scream “repair job.” Our patented precision cutting technology, by contrast, creates a clean, uniform slope that completely eliminates the trip hazard from edge to edge.

The difference is particularly noticeable at sidewalk edges and corners—areas that conventional grinders simply can’t reach effectively. Our cutting method addresses the entire width of the sidewalk, ensuring complete compliance rather than partial fixes.

The environmental impact is striking too. For every 100 sidewalk panels replaced conventionally, about 59 tons of concrete end up in landfills. Our method removes just 0.3 tons while reducing CO2 emissions by 1.3 metric tons. That’s sustainability you can feel good about.

Speed is another advantage—we typically complete each 4-foot section in just 15-20 minutes, allowing us to fix 15-20 trip hazards in a single day. This means less disruption for pedestrians and quicker resolution for property managers.

But perhaps most compelling is the cost difference. Our precision cutting method typically runs about one-tenth the cost of complete removal and replacement. When municipal budgets are tight (and when aren’t they?), this makes comprehensive compliance actually achievable rather than aspirational.

What are the maintenance requirements after trip hazard repair?

One of the best things about our ADA Trip Hazard Repair method is what doesn’t happen afterward—there’s no waiting. Unlike replacement or patching methods that require concrete curing time, sidewalks repaired with our precision cutting technique can be opened to pedestrian traffic immediately.

Maintenance is refreshingly minimal too. We recommend annual inspections to catch any new hazards early, but the repairs themselves don’t require special treatment. Some clients choose to apply a concrete sealer for extra weather resistance, but it’s not strictly necessary.

We do suggest keeping an eye on areas adjacent to repairs. Sometimes addressing one trip hazard can accelerate settlement in nearby sections—a phenomenon we explain to all our clients throughout South Florida, from Miami to West Palm Beach and beyond.

Documentation matters too. We provide before-and-after photographs of all repairs, which smart property managers keep on file. These records prove invaluable for demonstrating compliance efforts if questions ever arise.

As one property manager in Fort Lauderdale told us: “The best part of working with Florida Sidewalk Solutions is that once they’re done, I can forget about those trip hazards. No follow-up visits, no touch-ups needed—just compliant sidewalks.”

Can trip hazards be prevented before they develop?

While we’re experts at fixing trip hazards, we’d be remiss not to share some wisdom on preventing them in the first place. Though some factors (like soil conditions) are beyond control, several preventative measures can significantly reduce problems.

Proper initial construction makes an enormous difference. Adequate base preparation, appropriate concrete mix, well-placed control joints, and proper thickness all contribute to sidewalk longevity. These details might seem tedious during construction, but they pay dividends over decades of use.

Smart tree management prevents many of the most severe trip hazards we see. When planting near walkways, choose species with less aggressive root systems and consider installing root barriers. The right distance between trees and sidewalks can prevent the “sidewalk heave” that creates dramatic trip hazards.

Good drainage is often overlooked but crucial. Sidewalks should have proper cross-slope for water runoff, and the surrounding landscape should direct water away from walkway foundations. Standing water accelerates many deterioration processes.

Early intervention can prevent small issues from becoming ADA violations. Sealing cracks when they first appear and addressing minor settlement early can save substantial repair costs later.

In areas with expansive soils, soil stabilization techniques can significantly reduce sidewalk movement. Various geotextiles and soil treatments can minimize the expansion and contraction that wreaks havoc on concrete surfaces.

While these preventative measures are valuable, the reality is that most existing sidewalk networks will develop trip hazards over time. That’s why having Florida Sidewalk Solutions as your partner for ADA Trip Hazard Repair makes sense—we’ll help you maintain safe, compliant walkways year after year.

Conclusion

Maintaining ADA-compliant sidewalks isn’t just about checking boxes on a regulatory form—it’s about creating communities where everyone can steer public spaces safely and independently. ADA Trip Hazard Repair represents more than a technical service; it’s an investment in accessibility, safety, and inclusion for all community members.

At Florida Sidewalk Solutions, we take pride in our innovative approach to trip hazard repair throughout South Florida. Our precision cutting technology doesn’t just fix sidewalks—it transforms them into smooth, accessible pathways without the hassle and expense of complete replacement.

When you choose our patented cutting method, you’re getting several meaningful advantages:

Our repairs eliminate trip hazards completely, from edge to edge—no partial fixes or lingering issues that could still pose risks. The results blend seamlessly with your existing sidewalks, creating a uniform, professional appearance that maintains the aesthetic integrity of your property. And unlike replacement projects that can disrupt foot traffic for days, our repairs typically allow immediate use, minimizing inconvenience for pedestrians.

Perhaps most importantly for budget-conscious property managers and municipalities, our method typically costs about one-tenth of what you’d spend on removal and replacement. That’s not just good for your bottom line—it’s also better for the environment, generating significantly less waste and consuming fewer resources.

“Florida Sidewalk Solutions has the Trip Hazard market figured out in a simple way like no others. This is what we all want with contractors—trust,” shared one of our satisfied clients. That’s the kind of feedback that drives us to maintain our high standards across Miami, Fort Lauderdale, Coral Springs, West Palm Beach, and throughout Florida.

Why wait for an incident or complaint to address your sidewalk hazards? Proactive maintenance demonstrates your commitment to accessibility while protecting you from potential liability. The moment when someone trips and falls is always too late to address that uneven sidewalk you’ve been meaning to fix.

Our philosophy is straightforward but effective: “Cut it – don’t grind it!” This approach ensures complete elimination of hazards with superior results compared to conventional methods like grinding or scarifying. The difference is visible in the smooth, uniform transitions we create—and in the peace of mind our clients enjoy knowing their sidewalks are fully ADA-compliant.

Ready to transform your uneven sidewalks into smooth, accessible pathways? Contact Florida Sidewalk Solutions today for a comprehensive assessment. Let us show you how our innovative repair methods can help you achieve and maintain ADA compliance while protecting your budget and enhancing your property’s safety and accessibility.

After all, creating accessible communities isn’t just good compliance—it’s good citizenship. And with Florida Sidewalk Solutions, it’s also good business.