More Than Just a Crack in the Pavement

Concrete maintenance services are critical for municipal managers facing the daily challenge of keeping public walkways safe and ADA-compliant. Here’s what you need to know about professional sidewalk maintenance:

Essential Concrete Maintenance Services:

- Trip hazard removal – Eliminating vertical rises over 1/4 inch per ADA standards

- Precision concrete cutting – Leveling uneven slabs without full replacement

- ADA compliance assessment – Ensuring walkways meet federal accessibility requirements

- Root cause analysis – Addressing underlying issues like soil settlement and tree root damage

- Preventive maintenance – Regular inspections to catch problems before they escalate

When you’re managing miles of sidewalks on a tight budget, every decision matters. That uneven slab might look like a minor issue, but according to the ADA, any change in level over 1/4 inch at any joint or crack constitutes a trip hazard – and a potential lawsuit waiting to happen.

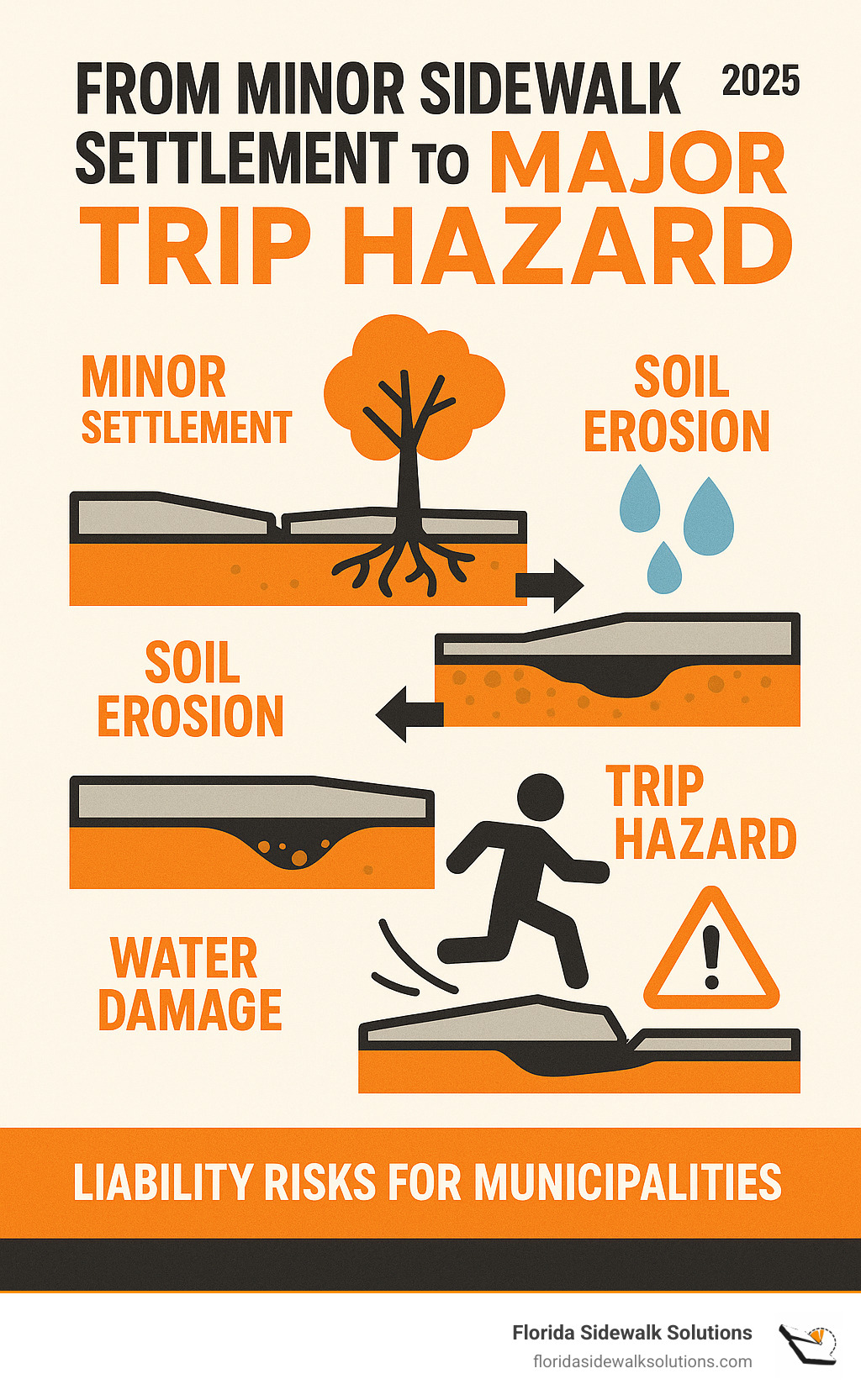

The hidden costs of neglect add up fast. Water infiltration leads to soil erosion beneath slabs. Freeze-thaw cycles make small cracks bigger. One uneven panel creates stress on adjacent sections, spreading the problem like dominoes.

Many municipalities try DIY fixes or hire general contractors with grinders and scabblers. But these approaches often create more problems than they solve. Grinding weakens the concrete surface and can’t reach edges or corners where most trip hazards occur. Patching creates unsightly repairs that fail quickly.

Modern concrete cutting technology offers a better path forward – one that’s more cost-effective than removal and replacement while delivering permanent, ADA-compliant results.

Concrete maintenance services terms to know:

Recognizing the Red Flags: When Your Sidewalk Becomes a Liability

Picture this: you’re walking down a familiar sidewalk when suddenly your toe catches on something. You stumble forward, arms flailing, trying to catch your balance. What caused this near-miss? An uneven concrete slab that seemed to appear out of nowhere.

This scenario plays out thousands of times daily across Florida. Those raised sidewalk panels pushing up from tree root pressure, the cracks causing height differences that create mini-cliffs in your walkway, and the persistent water pooling that signals trouble brewing beneath the surface – these aren’t just cosmetic annoyances.

These are liability lawsuits waiting to happen.

When we talk about concrete maintenance services, we’re really talking about protecting people and your wallet. Every uneven joint over 1/4 inch becomes an ADA violation. Every raised panel becomes a potential emergency room visit. Every crack that pools water becomes tomorrow’s bigger problem.

Tree root damage deserves special attention here in Florida. Our beautiful oak trees and aggressive root systems can turn a perfectly level sidewalk into a roller coaster overnight. What starts as a barely noticeable bump can become a significant hazard faster than you’d expect.

The Critical Role of Proactive Inspection

Smart property managers don’t wait for accidents to happen. They get ahead of problems with seasonal checks that catch issues while they’re still manageable.

Measuring uneven joints might sound tedious, but it’s your legal lifeline. That 1/4-inch ADA threshold isn’t arbitrary – it’s based on real-world trip hazard research. A simple gauge can tell you whether you’re looking at a minor maintenance issue or a major liability.

Documenting problem areas with photos and measurements creates a paper trail that shows you’re taking sidewalk safety seriously. This documentation also helps when understanding local municipal codes and proves you’re being proactive about maintenance.

Here’s the truth: if you can see a problem developing, it’s time for a professional assessment. Don’t wait until someone gets hurt. Florida Sidewalk Solutions maintains an A+ BBB Rating – BBB Accredited Business because we help property managers stay ahead of these issues before they become expensive problems.

The best concrete maintenance services focus on prevention, not just reaction.

Why Minor Issues Escalate Quickly

That tiny crack you’ve been ignoring? It’s working against you 24/7. Water intrusion through even hairline cracks starts undermining the soil beneath your concrete. In Florida’s climate, this process happens faster than you might think.

Freeze-thaw cycles might not be our biggest concern here, but temperature changes still cause concrete to expand and contract. This constant movement turns small cracks into bigger ones and makes uneven panels even more uneven.

Soil erosion beneath the slab is where things get expensive fast. Water finds its way under your concrete and slowly washes away the supporting soil. What started as a minor settlement issue becomes a major structural problem requiring extensive repair.

The domino effect is real and costly. One uneven panel puts stress on adjacent sections, creating new cracks and making existing problems worse. It’s like a chain reaction that spreads down your entire walkway.

Most importantly, increased liability over time means the longer you wait, the more expensive your eventual solution becomes. A small trip hazard today becomes a major lawsuit tomorrow.

This is why Florida Sidewalk Solutions focuses on early intervention with our patented cutting technology. We can level those uneven joints permanently, stopping the escalation before it empties your maintenance budget.

The Pitfalls of DIY vs. Professional Concrete Maintenance Services

Picture this: you’re staring at an uneven sidewalk panel, and you’re thinking, “How hard could it be to fix this myself?” We get it. The appeal of a quick DIY solution or hiring the cheapest contractor with a concrete grinder is real, especially when budgets are tight. But here’s the thing about concrete maintenance services for trip hazards – what looks like a simple fix often turns into a bigger headache down the road.

Those DIY patch kits you see at the hardware store? They’re like putting a band-aid on a broken bone. They might fill a crack or smooth out a small lip temporarily, but they don’t address why that concrete moved in the first place. Was it tree roots pushing up from below? Soil settling underneath? Water washing away the foundation? The patch kit doesn’t care – and that’s exactly why it fails so quickly.

The same goes for conventional methods like concrete grinding and scabbling. These approaches create mountains of dust and debris that nobody wants to deal with. More importantly, they’re essentially giving your sidewalk a haircut when what it really needs is surgery. You’re just shaving down the high spots without fixing the underlying problem.

The result? An unsightly patch that looks worse than the original damage, and a problem that’s guaranteed to come back.

Why Grinding and Patching Fall Short

Let’s be honest about why grinding and patching are such poor choices for concrete maintenance services. When contractors show up with grinders, they’re offering you a temporary band-aid solution that creates more problems than it solves.

Grinding weakens your concrete surface by removing the hard, dense top layer that took years to develop. What’s left behind is softer aggregate that’s much more vulnerable to damage. It’s like removing the protective shell from an egg – you’ve just made everything underneath more fragile.

Here’s what really gets us: grinding can’t reach the edges where most trip hazards actually occur. Those corner spots where one panel meets another? The grinder can’t get there effectively, leaving you with the same hazard you started with. Meanwhile, you’ve created an ugly, discolored patch that screams “cheap repair job.”

The root cause remains untouched. If soil erosion caused your sidewalk to settle, grinding the high spots doesn’t stop that erosion. If tree roots pushed up a panel, grinding doesn’t address those roots. You’re essentially ignoring the source of the problem while making the surface weaker and uglier.

Even worse, improper grinding can mess with your sidewalk’s natural drainage, creating new spots where water pools. That standing water accelerates concrete damage and makes your original problem worse over time.

The Professional Advantage: Precision, Safety, and Durability

When you choose professional concrete maintenance services from Florida Sidewalk Solutions, you’re getting something completely different. We’re not just fixing the symptom – we’re solving the actual problem with precision that DIY methods can’t match.

Our patented cutting technology can reach those tricky edges and corners where most trip hazards live. Unlike grinders that leave rough, weakened surfaces, our cutting method creates smooth, level transitions that look natural and last for years.

Minimal disruption means your sidewalks are back in service immediately after we’re done. No waiting for patches to cure, no dust clouds bothering your neighbors, and no water waste from grinding operations. We show up, fix the problem cleanly, and get out of your way.

The expertise in material science and soil mechanics that our team brings can’t be bought at a hardware store. We understand why concrete moves, how to prevent future problems, and what it takes to create a repair that actually lasts. When we guarantee our results, we mean it – because we’ve addressed the real cause of your trip hazard, not just its appearance.

Our specialized equipment and proven methods ensure your sidewalks meet ADA compliance standards while looking great and staying safe for years to come. That’s the difference between a professional solution and a temporary fix.

The Superior Solution: How Modern Sidewalk Leveling Works

Picture this: instead of tearing up your entire sidewalk or grinding away at it with loud, dusty equipment, there’s a better way. Modern concrete maintenance services have evolved beyond the old-school methods that left you with unsightly patches and temporary fixes.

Our specialized cutting technology works like a precision surgeon for concrete. We bring in equipment specifically designed for trip hazard removal, targeting exactly what’s causing the problem without disturbing the rest of your walkway. The machine creates smooth, level transitions by making precise cuts that eliminate the vertical differences between concrete slabs.

What makes this approach so effective is the bevel cutting technique. Instead of creating harsh edges that could become new trip points, we create gentle slopes that flow naturally from one section to the next. It’s precision leveling that actually looks good when we’re done.

The best part? This is a clean operation. No clouds of concrete dust choking pedestrians. No water needed for the cutting process. No piles of debris to haul away. You get professional results without the mess that comes with conventional methods.

A Closer Look at a Patented Concrete Maintenance Services Method

Here’s where things get really interesting. Our patented method for concrete maintenance services completely changes how we think about sidewalk repair. Instead of the “tear it out and start over” mentality, we remove the hazard without replacement.

The process is surprisingly straightforward. We assess your sidewalk to identify every trip hazard, then our specialized equipment makes precise cuts to eliminate the vertical differences. What you end up with is a clean, permanent repair that addresses the actual problem, not just the symptoms.

The cost-effectiveness compared to demolition is remarkable. We’re talking about savings that often exceed 50% compared to removal and replacement. That means you can fix twice as many hazards with the same budget, or put those savings toward other property improvements.

Our method creates results that are superior in quality compared to grinding or patching. The repaired areas blend seamlessly with the existing concrete, maintaining both safety and curb appeal. Plus, the sidewalk is ready for immediate use once we’re finished – no waiting for concrete to cure or patches to set.

Want to see it in action? View this post on Instagram to watch our process transform a hazardous sidewalk into a smooth, safe walkway.

Ensuring ADA Compliance for Your Property

Let’s talk about something that keeps property managers up at night: ADA compliance. The Americans with Disabilities Act isn’t just a guideline – it’s federal law with real consequences for non-compliance.

The 1/4-inch vertical rise rule is the critical measurement you need to know. Any change in level over 1/4 inch at joints or cracks creates a trip hazard and violates ADA standards. Our precision cutting method ensures every repair meets or exceeds this requirement.

But compliance goes beyond just that quarter-inch measurement. Slope requirements matter too. Walkways need proper cross slopes and running slopes to be truly accessible. While our primary focus is trip hazard removal, addressing uneven surfaces often improves overall slope compliance as a bonus.

Avoiding lawsuits and fines isn’t just about legal protection – it’s about doing the right thing. Non-compliance can result in costly litigation and significant penalties. More importantly, accessible walkways benefit everyone in your community.

This is especially critical for commercial and public properties. If you manage a business, school, healthcare facility, or municipal property, ADA compliance isn’t optional. It’s a legal obligation that demonstrates your commitment to accessibility and inclusion.

Our patented cutting method delivers the precision needed for reliable ADA compliance. We distinguish ourselves with superior technology and competitive pricing, making accessibility both achievable and affordable for property owners throughout Florida.

Frequently Asked Questions about Sidewalk Maintenance and Repair

When property managers and municipal clients first learn about our specialized approach to concrete maintenance services, they naturally have questions. After all, most people are familiar with the old ways of doing things – grinding, patching, or tearing everything out and starting over. Our precision cutting method is different, and we’re happy to explain exactly how it works and why it’s such a game-changer for sidewalk safety.

How much does professional trip hazard removal cost?

Here’s the good news: our precision cutting method costs significantly less than full concrete replacement. While traditional concrete replacement can run anywhere from $10 to $30 per square foot, our targeted approach focuses only on the problem area – the actual trip hazard itself.

Cost per linear foot varies based on several factors. The number of hazards, the complexity of the cuts needed, and your specific location all play a role in pricing. Whether you’re managing sidewalks in Davie, Fort Lauderdale, Coral Springs, Boca Raton, West Palm Beach, Miami, or Fort Myers, we consistently deliver savings that often exceed 50% compared to removal and replacement costs.

Think about it this way: instead of ripping out entire sections of perfectly good concrete just to fix a small raised edge, we surgically remove only what’s causing the problem. This comparison to replacement costs makes our method a smart long-term investment. You can address more hazards within your budget, and you’ll avoid the much higher costs that come with personal injury lawsuits when someone gets hurt on an uneven sidewalk.

The value of a long-term solution becomes clear when you consider that repairing concrete is often more economical than full replacement and extends the lifespan of your existing walkways.

Is concrete cutting a permanent fix for uneven sidewalks?

Absolutely. Our concrete cutting method provides a permanent solution for addressing the hazard permanently. Unlike grinding, which just shaves down the surface like putting a band-aid over the problem, our patented process creates a precise, level transition that eliminates the vertical displacement entirely.

We’re not just masking the issue – we’re removing the actual trip hazard by cutting the concrete to make it perfectly level. This engineered approach ensures how it prevents re-occurrence at the same spot. Once we’ve made our precision cuts, that specific location won’t develop the same problem again.

Now, it’s important to be realistic here. New hazards can develop elsewhere on your sidewalk due to ongoing environmental factors like tree roots continuing to grow or soil settling over time. But the section we’ve repaired? That’s fixed for good.

The longevity of the repair speaks to our superior technology and methodology. We stand behind our work because we know our precision cutting creates lasting results. Our warranty and guarantees reflect our confidence in delivering a permanent solution that maintains both safety and structural integrity.

How long does the sidewalk repair process take?

One of the biggest advantages of our precision cutting method is how efficiently we can restore safety to your walkways. Minimal disruption is built right into our process from start to finish.

For minor repairs, we can often complete the work within a single day. More extensive projects involving many linear feet of sidewalk typically wrap up in just a few days. We’ve had clients tell us about large-scale projects that were completed in just two days – something that would take weeks with traditional removal and replacement methods.

Our typical project timeline depends on the scope, but our specialized equipment allows us to repair a significant number of linear feet per day. How many feet can be repaired per day varies based on the complexity of the hazards, but we’re consistently much faster than conventional methods.

Here’s what really sets us apart: immediate use of the sidewalk after repair. The moment we finish cutting, your sidewalk is ready for pedestrian traffic. There’s no waiting for concrete to cure, no extended barricades blocking access, and minimal inconvenience to the public or your property’s daily operations.

This efficiency translates directly into less downtime and quicker resolution of safety hazards. Your walkways go from liability to asset in record time, and everyone can get back to their normal routine without missing a beat.

Secure Your Peace of Mind with Professional Sidewalk Solutions

Picture this: you’re walking down a sidewalk that’s perfectly level, smooth, and safe. No more watching your step or worrying about someone tripping and getting hurt. That’s the peace of mind that comes with professional concrete maintenance services focused on trip hazard removal.

We’ve covered a lot of ground in this guide, from recognizing the warning signs of dangerous sidewalks to understanding why DIY fixes just don’t cut it. The truth is, when it comes to sidewalk safety and ADA compliance, there’s no substitute for specialized expertise.

Improved safety is the foundation of everything we do. When you eliminate trip hazards properly, you’re protecting everyone who uses those walkways – from elderly residents to children on bikes to people using wheelchairs. It’s about creating spaces where people can move confidently without fear.

The cost savings speak for themselves. Our patented cutting method costs significantly less than tearing out and replacing concrete slabs. You’re often looking at half the expense of traditional removal and replacement, which means you can fix more hazards with the same budget.

Liability reduction might not be the most exciting topic, but it’s crucial for property managers and municipalities. Every uneven slab over that critical 1/4-inch ADA threshold is a potential lawsuit waiting to happen. Professional trip hazard removal eliminates that risk completely.

Perhaps most importantly, you’re investing in long-term value. Our method doesn’t just mask the problem like grinding does – it actually removes the hazard permanently. The repaired sections won’t create the same problem again, giving you lasting results you can count on.

At Florida Sidewalk Solutions, we’ve built our reputation on doing one thing exceptionally well: removing trip hazards from sidewalks and concrete walkways. Our patented technology cuts concrete to create perfectly level surfaces without the dust, mess, or high costs of conventional methods. We’re not just another concrete company – we’re specialists who focus exclusively on making sidewalks safe and ADA-compliant.

Don’t let uneven sidewalks keep you up at night worrying about accidents or lawsuits. When you partner with true specialists in trip hazard removal, you’re choosing expertise, efficiency, and results that last.