What is an ADA Compliant Ramp?

ADA compliant ramp specifications are detailed requirements set by the Americans with Disabilities Act to ensure ramps are safe and accessible for people with disabilities. These specifications cover everything from slope ratios to handrail heights, creating a standardized approach to accessibility.

Key ADA Ramp Specifications:

- Maximum slope: 1:12 ratio (1 inch rise per 12 inches of length)

- Minimum width: 36 inches clear space

- Maximum rise per run: 30 inches before requiring a landing

- Landing size: Minimum 60 inches long, as wide as the ramp

- Handrails: Required for rises over 6 inches, mounted 34-38 inches high

- Cross slope: Maximum 1:48 ratio to prevent sideways rolling

The ADA is a civil rights law signed in 1990 that prohibits discrimination based on disability. For municipal maintenance managers, these ramp specifications aren’t just guidelines—they’re legal requirements that protect your city from lawsuits while ensuring equal access for all residents.

Ramps serve people using wheelchairs, walkers, canes, and other mobility aids. They also help parents with strollers and workers moving equipment. But here’s what many don’t realize: any walking surface with a slope greater than 1:20 is considered a ramp and must meet ADA standards.

The stakes are high. Non-compliant ramps create barriers that can exclude people from accessing public buildings, sidewalks, and services. More importantly, they create safety hazards that can lead to serious injuries and expensive liability claims.

Simple guide to ada compliant ramp specifications terms:

Understanding the Core ADA Compliant Ramp Specifications

Getting the measurements right is where accessibility begins. These fundamental numbers aren’t just bureaucratic requirements—they’re the difference between a ramp that works for everyone and one that creates barriers. Let’s break down the core ADA compliant ramp specifications that form the foundation of safe, usable ramps.

Key Slope and Rise ADA Compliant Ramp Specifications

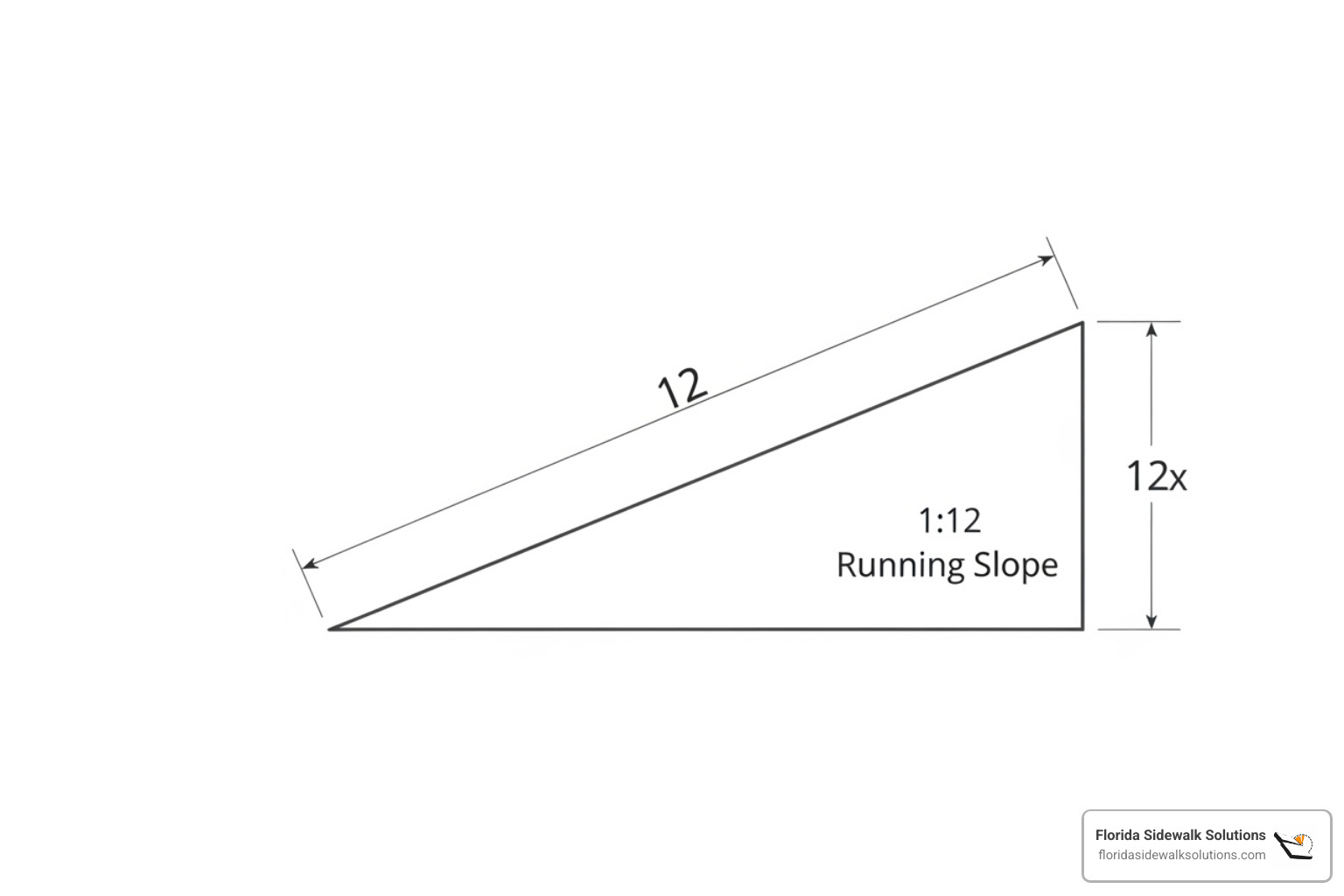

Think of slope as the heartbeat of ramp design. The running slope—the incline along the direction of travel—has a strict maximum of 1:12 ratio for new construction. This means for every inch your ramp rises, it must stretch at least 12 inches forward.

Here’s a real-world example: if your building entrance sits 24 inches above ground level, your ramp needs to extend at least 288 inches (24 feet) to meet this standard. It might seem long, but this gentle grade makes the difference between a manageable climb and an exhausting struggle for someone using a manual wheelchair.

The cross slope is equally important but often overlooked. This sideways tilt cannot exceed 1:48 ratio (about 2%). Why does this matter? Picture trying to roll straight on a tilted surface—you’d constantly drift to one side. This specification prevents that sideways pull while allowing just enough slope for proper water drainage.

Every ramp also has built-in rest stops. The maximum rise for any single ramp run is 30 inches, which typically translates to a maximum run length of 30 feet. After climbing 30 inches vertically, users must have a level landing to rest before continuing. It’s like mandatory rest stops on a long journey—they prevent fatigue and make the trip manageable for everyone.

For more detailed calculations and practical applications, visit our guide on ADA Ramp Slope. The complete technical specifications are available in the 2010 ADA Standards for Accessible Design.

Width and Landing Requirements

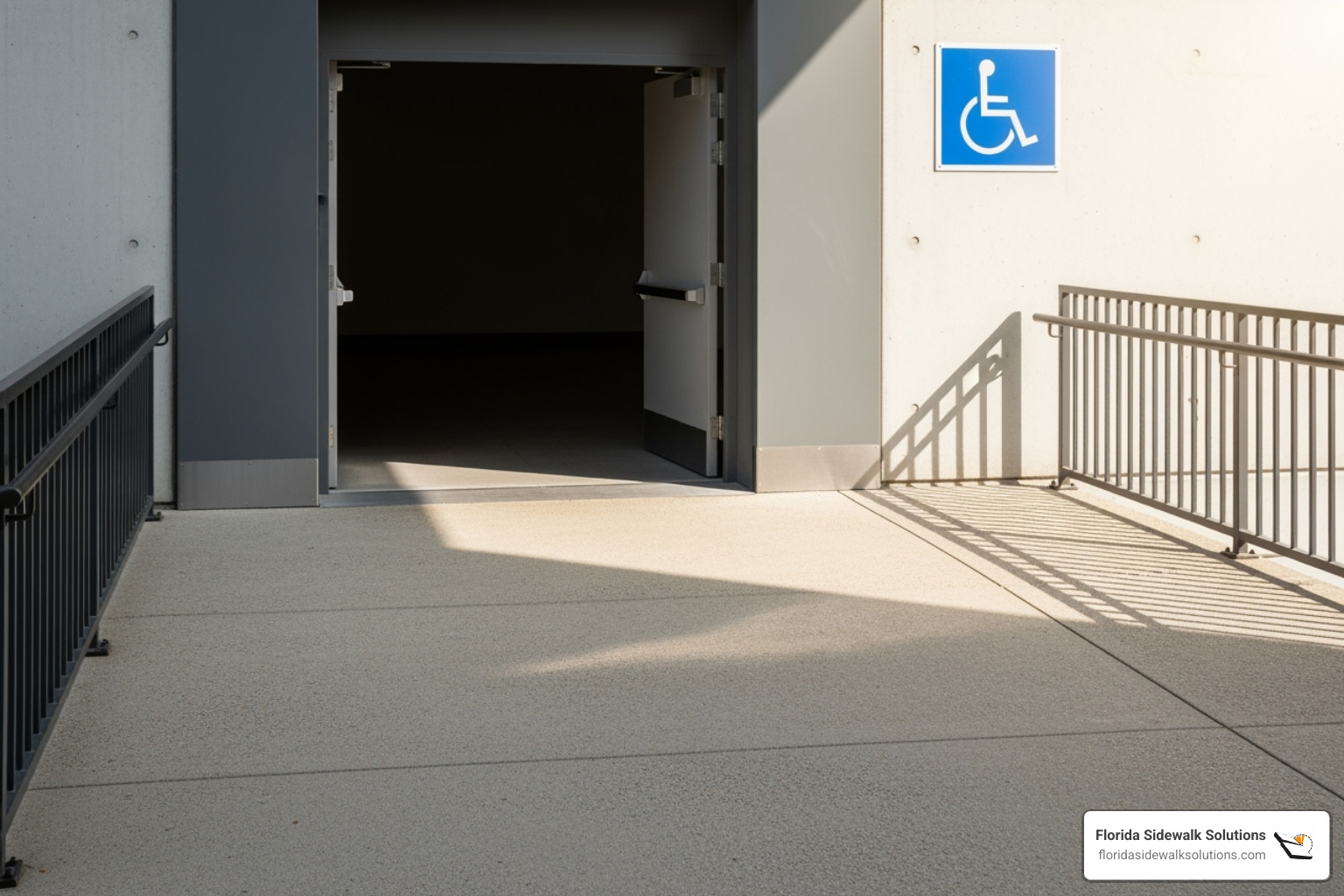

Width isn’t just about fitting through—it’s about moving comfortably and safely. Every ramp must maintain a minimum clear width of 36 inches between any obstacles, including handrails. This space accommodates wheelchairs, walkers, and other mobility aids while providing room for slight course corrections.

Think of this width as a highway lane. Too narrow, and traffic gets dangerous. Too wide might be nice but isn’t always practical. The 36-inch standard strikes the right balance between accessibility and efficient use of space.

Landing requirements are where many ramps fail compliance, often because people underestimate their importance. These level platforms serve as crucial rest areas and turning spaces. Top and bottom landings must be at least as wide as the ramp and extend 60 inches minimum in the direction of travel.

When ramps change direction, switchback landings need even more space—60×60 inches minimum. This square footage allows someone in a wheelchair to make a complete turn without backing up or struggling with tight corners.

Doorway maneuvering clearance adds another layer of complexity. If a door opens onto a ramp landing, you need additional space for the door swing and maneuvering. It’s like choreographing a dance—every movement needs adequate space to happen smoothly.

Over time, even well-built ramps can develop problems. Settling concrete can create uneven transitions at landings, turning compliant ramps into trip hazards. If your ramp landings have developed these issues, our Handicap Access Ramp Repair services can restore proper levels and ensure continued compliance.

Essential Safety Features: Surfaces, Handrails, and Edge Protection

Beyond basic dimensions, ADA standards mandate specific safety features that prevent slips, falls, and other accidents. These elements are critical for a truly accessible ramp.

Ramp Surface and Outdoor Conditions

When it comes to ada compliant ramp specifications, the surface beneath your feet matters just as much as the slope you’re climbing. Think about it – even the most perfectly angled ramp becomes dangerous if someone slips on a wet or uneven surface.

Ramp surfaces must be firm, stable, and slip-resistant under all weather conditions. This means saying goodbye to loose gravel, uneven paving stones, or any slick, polished surfaces that turn into ice rinks when wet. Common materials like concrete, asphalt, wood, or metal work perfectly fine, as long as they have a proper non-slip finish.

Here’s a detail that might surprise you: any openings in the ramp surface must be small enough that a 1/2 inch sphere cannot pass through. Why? Because small wheels, crutch tips, or cane tips can get caught in larger gaps, causing dangerous falls. It’s one of those specifications that seems minor until you realize how important it is for safety.

Outdoor ramps face unique challenges, especially here in Florida where we know a thing or two about sudden downpours. Proper drainage becomes absolutely critical – ramps must be designed to prevent water accumulation on walking surfaces. Cross slope we mentioned earlier? It can’t exceed 1:48, which helps water run off efficiently while still keeping the ramp stable for sideways movement.

Even the most perfectly designed ramp can develop problems over time. Concrete settles, creating uneven transitions that can turn compliant ramps into trip hazards. That’s where our expertise in ADA Compliant Sidewalk Repair comes in handy – we address those surface irregularities that can undermine an otherwise safe ramp.

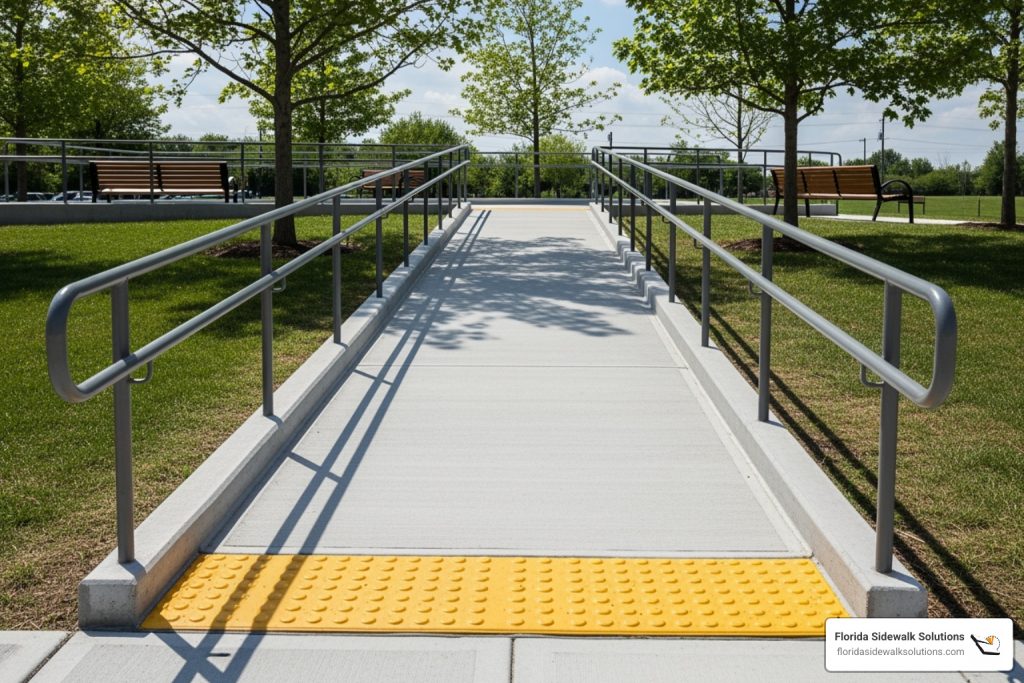

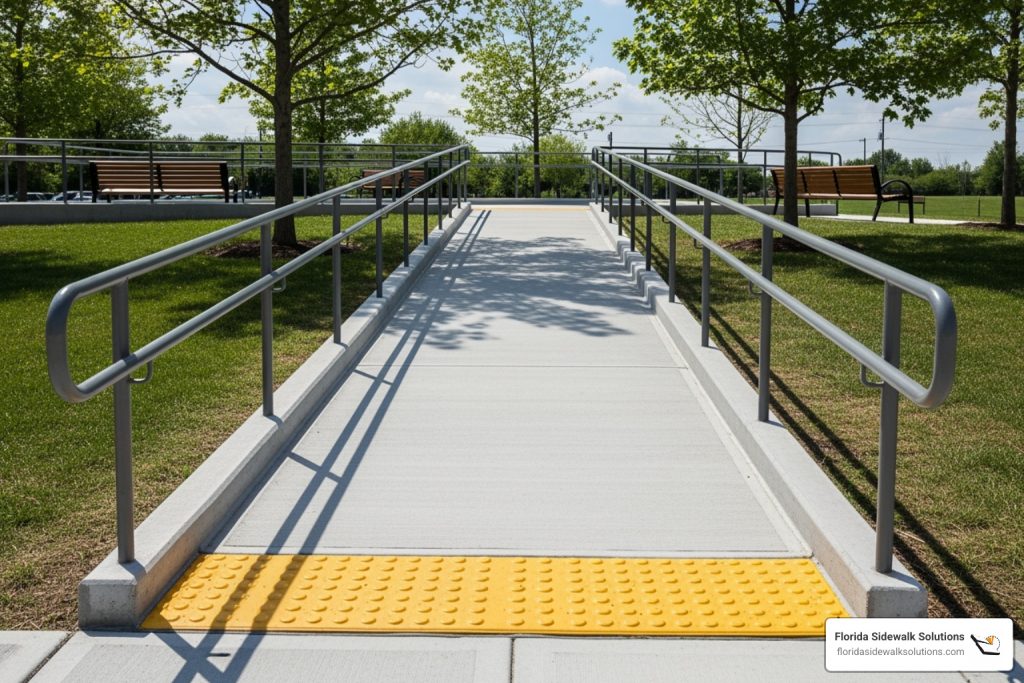

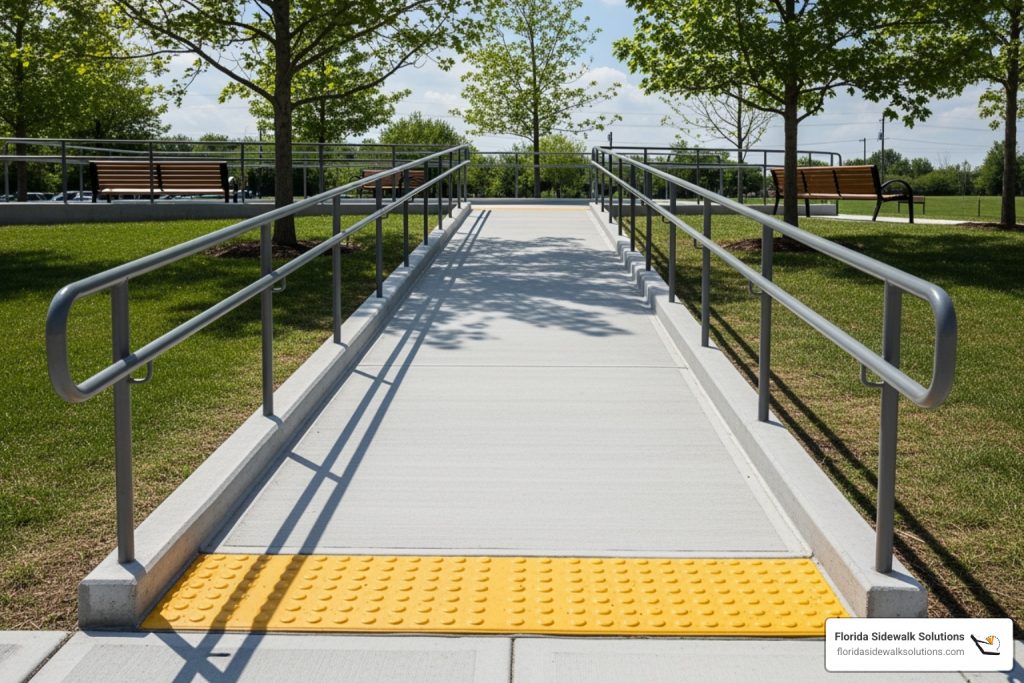

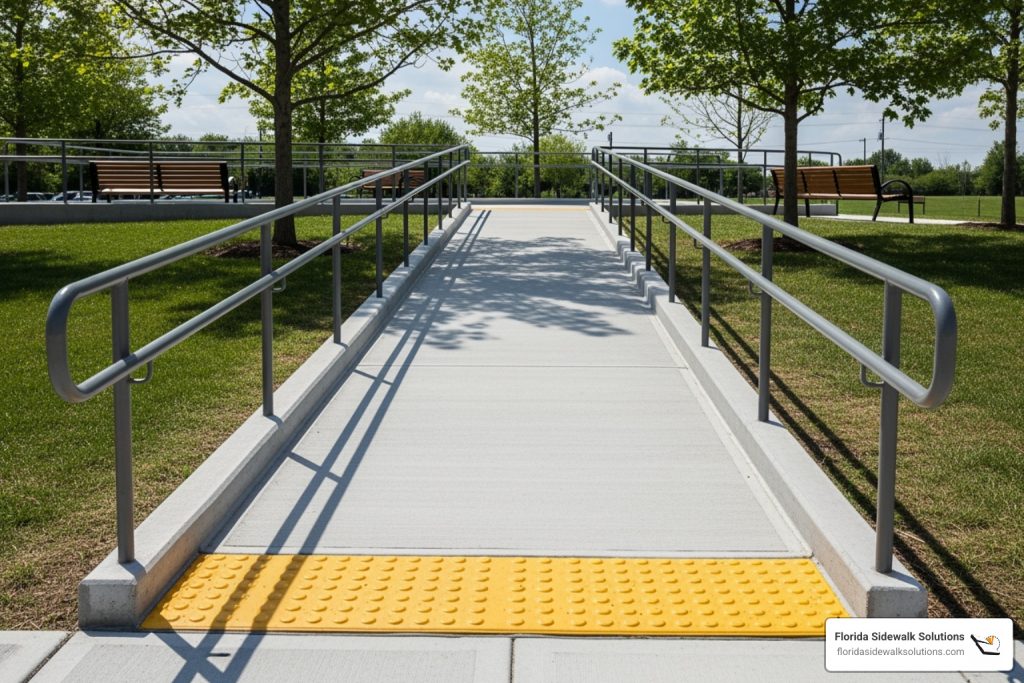

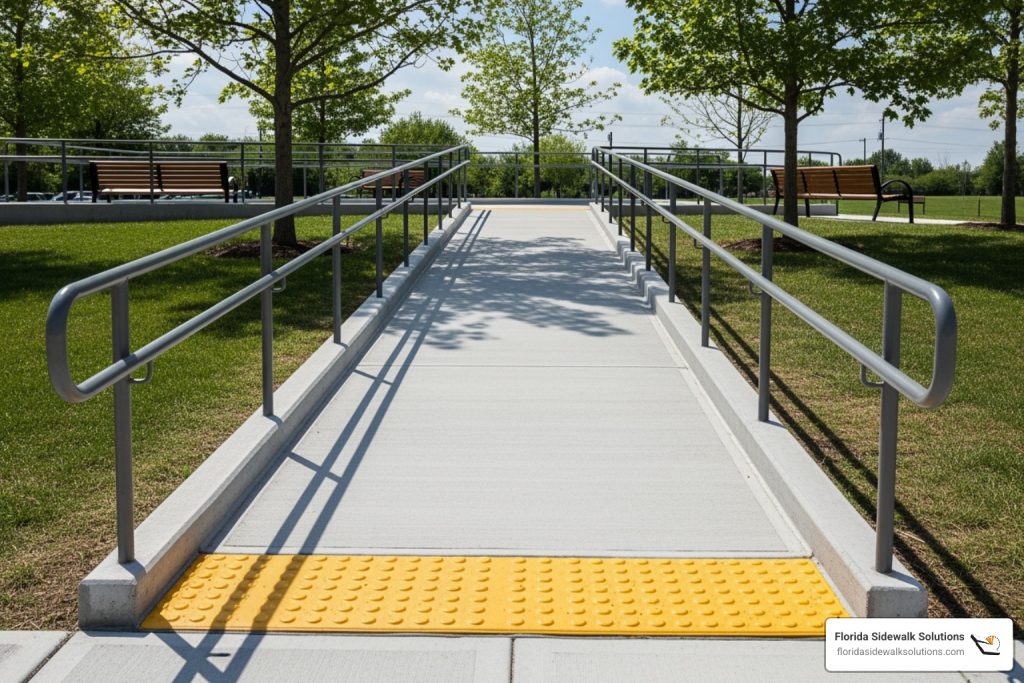

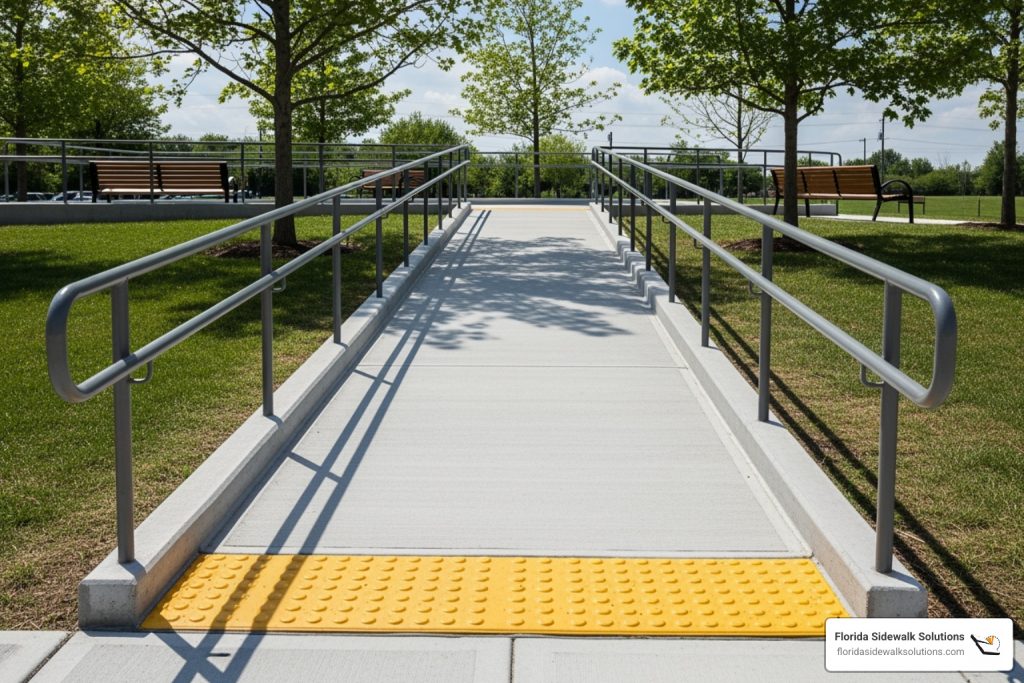

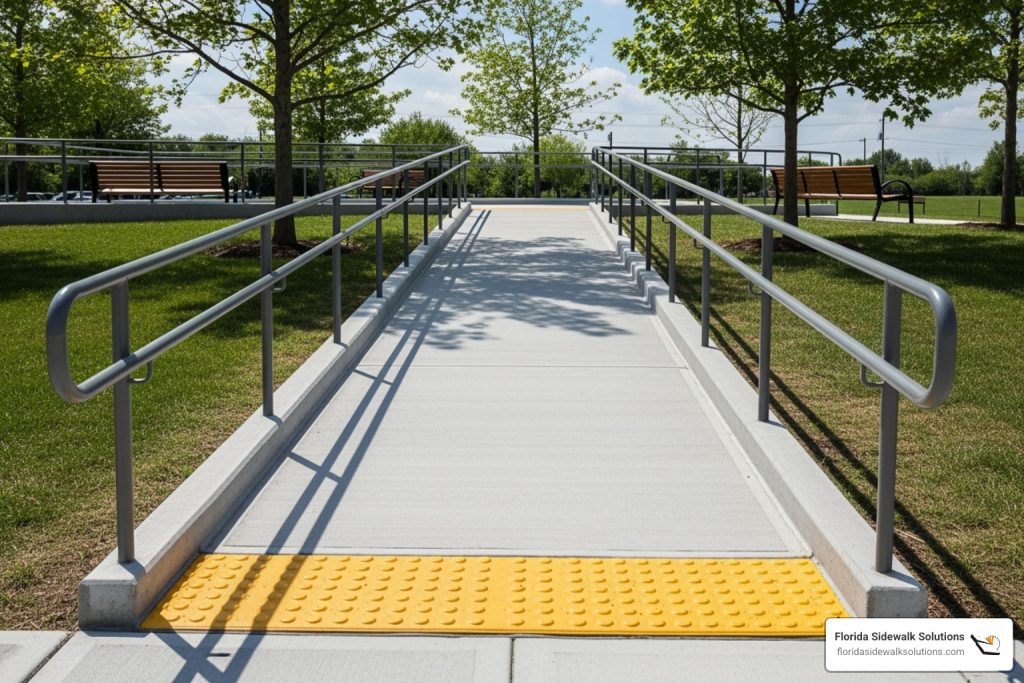

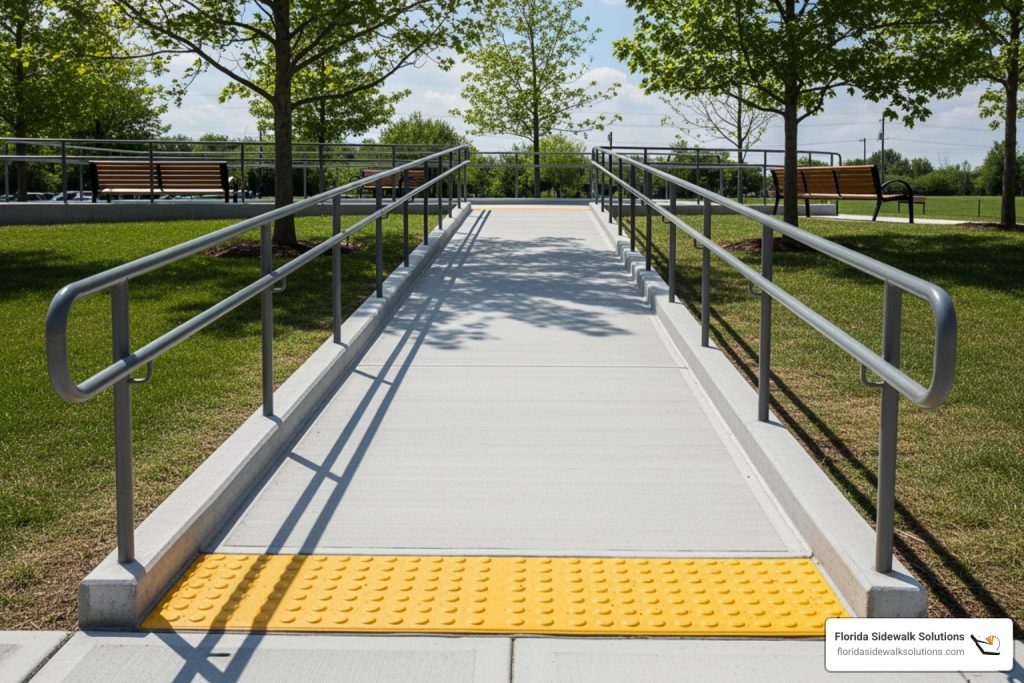

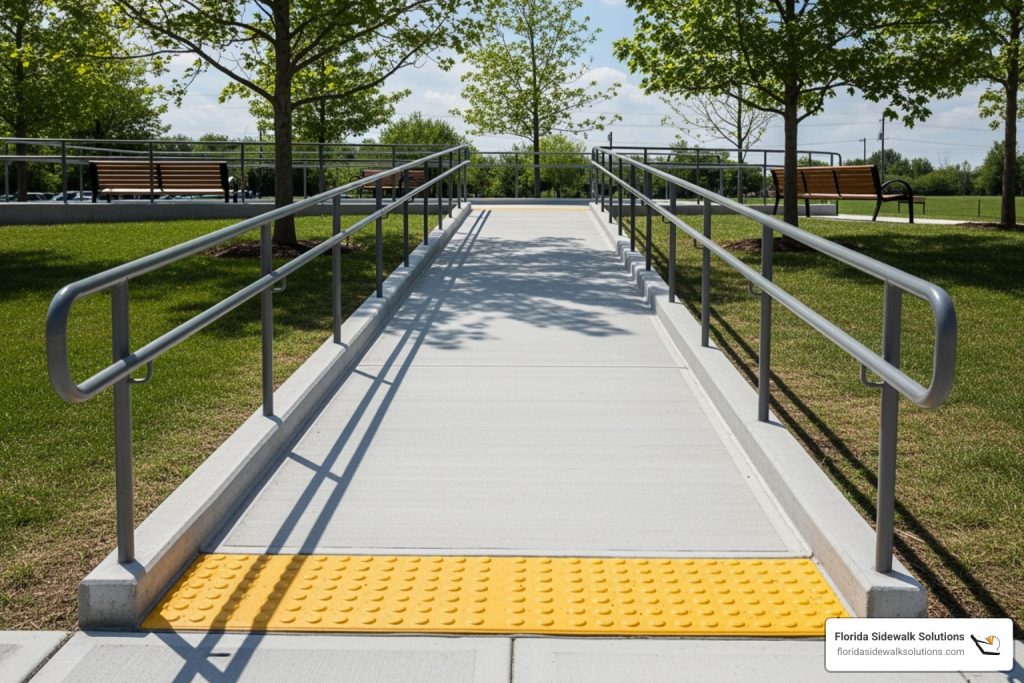

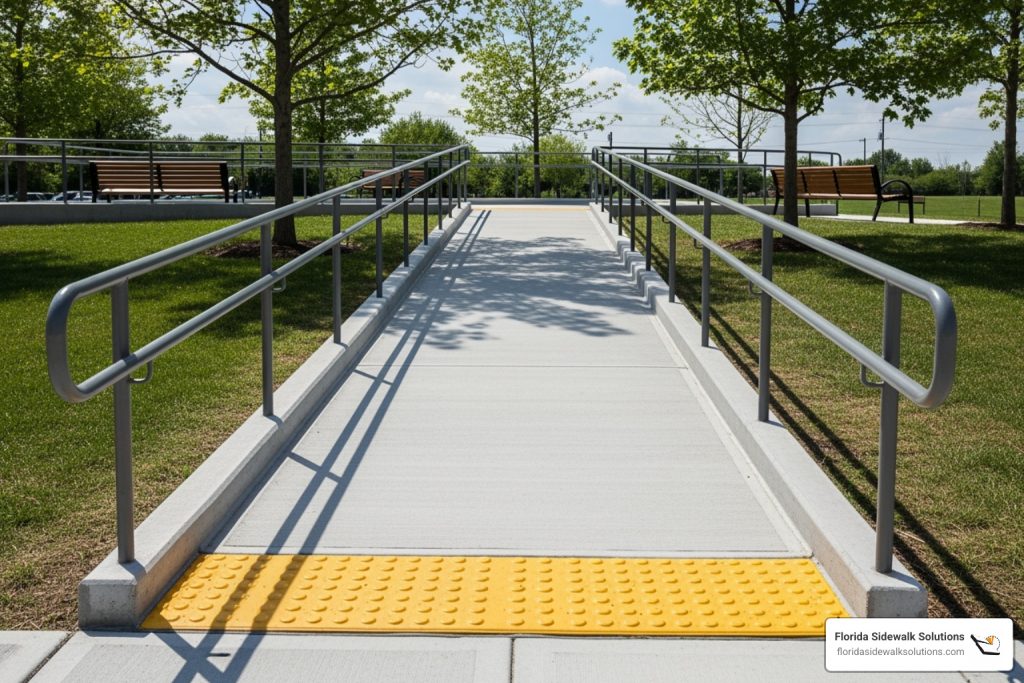

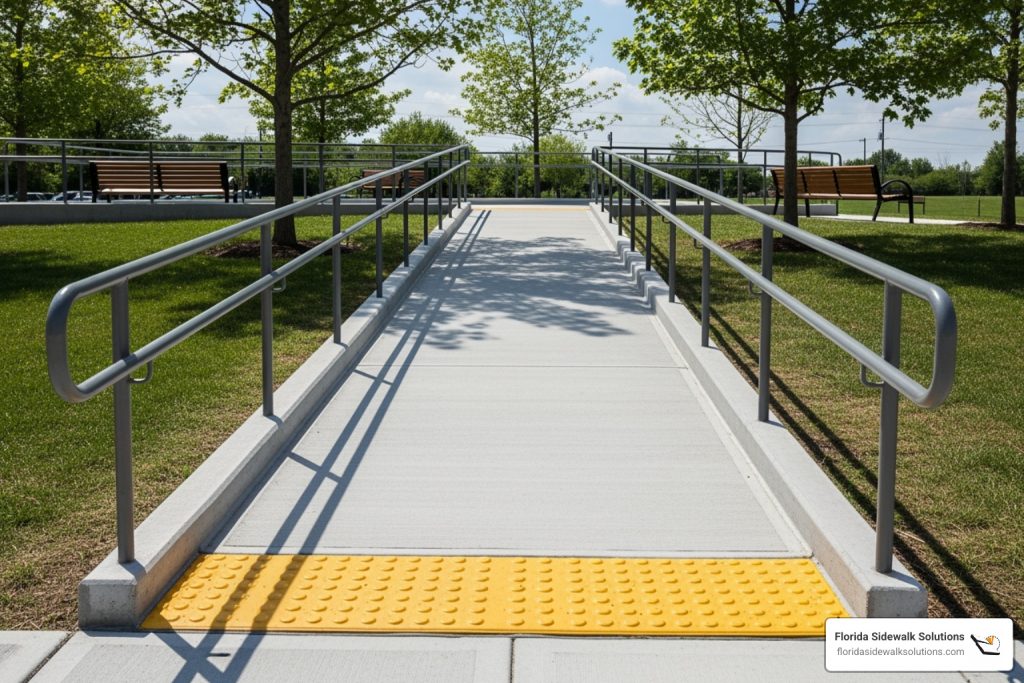

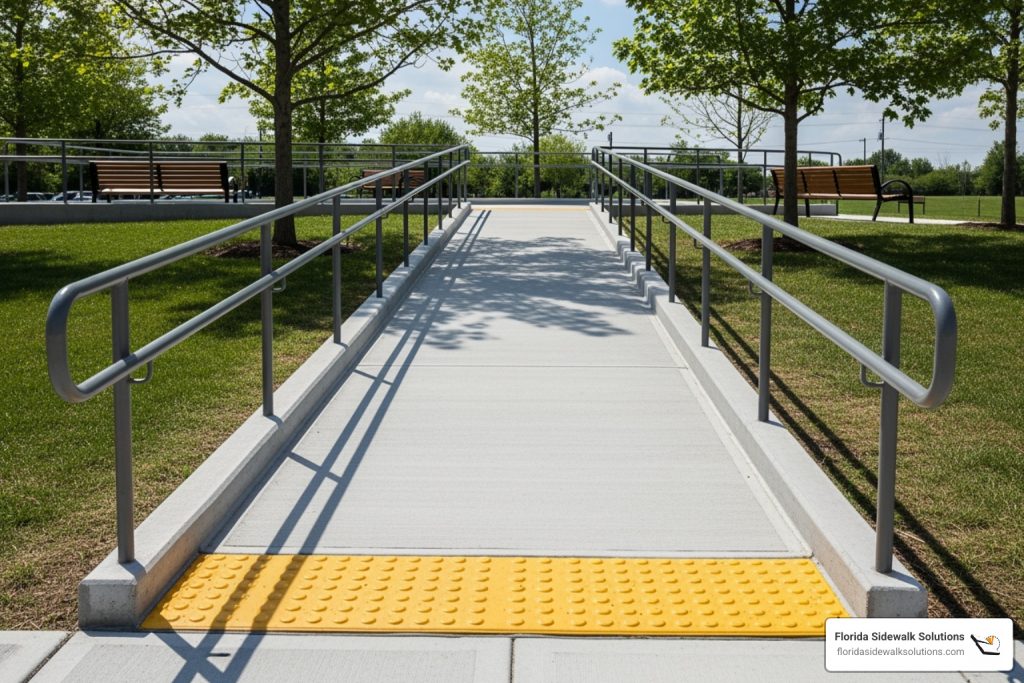

Handrail and Guardrail ADA Compliant Ramp Specifications

Handrails are the unsung heroes of ada compliant ramp specifications. They provide that crucial support and balance that can make the difference between a confident journey and a scary one. The good news? They’re only required when a ramp has a rise greater than 6 inches or extends more than 72 inches horizontally.

When handrails are needed, they must be installed at a height between 34 and 38 inches above the ramp surface. This range accommodates everyone from shorter individuals to taller users, ensuring comfortable grip for all.

Continuity is key – handrails must run the full length of each ramp segment without interruption. On switchback ramps, the inside handrail must remain continuous throughout the entire journey. Think of it as an unbroken lifeline that users can rely on.

The 12-inch extensions at the top and bottom of ramp runs are particularly thoughtful. These horizontal extensions give people a chance to regain their balance before stepping onto or off the ramp. It’s like having a moment to prepare for what’s coming next.

Grip size matters more than you might think. Round handrails should have a diameter between 1.25 to 2 inches – big enough to grab securely, but not so large that smaller hands can’t wrap around them. Non-round handrails have their own specifications, but the goal is always the same: a comfortable, secure grip.

That 1.5-inch clearance between the handrail and wall prevents scraped knuckles – a small detail that makes a big difference in user comfort. The surface must be smooth and able to withstand 200 pounds of force, proving it can handle real-world use.

Now, here’s where people sometimes get confused: handrails and guardrails serve different purposes. A handrail is designed for grip and support, while a guardrail is a taller barrier (at least 42 inches high) that prevents falls from heights. Guardrails are about protection from drop-offs, while handrails are about providing stability during the journey.

Edge Protection Explained

Edge protection might sound technical, but it’s really about common-sense safety. When there’s a vertical drop-off of more than half an inch beside a ramp, something needs to prevent people from accidentally rolling or stepping off the edge.

Curb protection is the most straightforward approach. A curb or barrier along the ramp’s edge must be at least 4 inches high – tall enough to catch a wheelchair wheel or guide a walking aid back onto the safe surface. Think of it as a gentle guardrail at ground level.

The alternative is extended surface protection, where the ground surface extends 12 inches beyond the handrail. This creates a wider safe zone that naturally prevents people from getting too close to the edge. It’s like having a safety buffer built right into the design.

The beauty of edge protection is its simplicity – it’s about giving everyone the confidence to use the ramp without worrying about accidentally veering off course. These safety features work together to create an environment where accessibility and security go hand in hand.

Understanding these critical safety elements is part of what we cover in Paving The Way Understanding ADA Sidewalk Standards, helping ensure your walkways meet every requirement for safe, accessible passage.

Special Considerations: Existing Buildings, Curb Ramps, and Applicability

ADA requirements can vary based on the situation. This section covers specific rules for modifying existing structures, the unique design of curb ramps, and who is legally required to comply.

Alterations and Exceptions for Existing Sites

When it comes to existing buildings and facilities, ada compliant ramp specifications can be a bit more forgiving, but the goal of accessibility never wavers. Think of it this way: the ADA doesn’t expect you to tear down every older building, but it does expect you to make reasonable improvements when possible.

The ADA operates on a “readily achievable” standard for existing facilities. This means barriers must be removed where it’s easily accomplishable without much difficulty or expense. However, here’s the catch: any alterations you make to existing facilities must comply with new construction requirements to the maximum extent feasible. You can’t make things less accessible than they already are!

We understand that space can be a real challenge in older structures. Sometimes you’re working with a narrow sidewalk or a cramped entrance area where a full 30-foot ramp just isn’t possible. Fortunately, the ADA recognizes these limitations and provides specific exceptions to the standard 1:12 slope for existing sites with space restrictions.

For very small height changes, a slope of up to 1:8 is permitted for a rise of 3 inches or less. This steeper slope works when you’re dealing with something like a single small step where a full 1:12 slope would require an impractically long ramp.

When you need to overcome slightly larger height differences, a slope of up to 1:10 is permitted for a rise of 6 inches or less. This allows for a moderately steeper ramp while still maintaining reasonable safety standards.

These exceptions are strictly limited to the specified rise amounts, and the standard 1:12 slope should always be your first choice if space allows. We often work with property owners to find creative solutions that maximize accessibility within existing constraints. Our team at Handicap Ramp Repair In Florida frequently helps assess how to best apply these guidelines in real-world scenarios.

Curb Ramps vs. General Ramps

While both fall under ada compliant ramp specifications, curb ramps and general building ramps are quite different animals. Understanding these differences is crucial for proper compliance and safety.

General building ramps are the ones you typically see leading into buildings. They’re designed for continuous travel, often with multiple runs and landings, focusing on providing a smooth, gradual incline for entry into or movement within a facility. These ramps help people steer between different floor levels or overcome larger elevation changes.

Curb ramps serve a completely different purpose. Their primary job is connecting sidewalks to streets at pedestrian crossings, allowing wheelchair users and others with mobility aids to safely transition from the curbed sidewalk to the street level.

The most distinctive feature of curb ramps is the requirement for detectable warnings – those small, dome-shaped bumps you see at street crossings, often in bright yellow or contrasting colors. These aren’t just decorative; they’re crucial safety features that alert blind and low-vision pedestrians that they’re about to enter a street or hazardous area. The detectable warning surface must extend the full width and depth of the curb ramp where required.

Flared sides are another unique characteristic of many curb ramps. These sloped edges on either side of the main ramp run prevent tripping hazards for pedestrians who might walk across the ramp’s side. In some alteration situations, they can also accommodate wheelchair maneuvering when a full top landing isn’t feasible, but their slope must be carefully controlled.

The gutter slope adjacent to curb ramps requires special attention too. It typically cannot exceed 1:20 (5%) to prevent water pooling and ensure smooth transitions. Curb ramps at marked crossings must be wholly contained within the crosswalk, and while diagonal curb ramps are allowed, they have specific clearance requirements.

It’s worth noting that detectable warning requirements can vary depending on the type of facility and funding sources. For comprehensive details on these nuances, check out Chapter 4: Ramps and Curb Ramps – Access-Board.gov.

Who Needs to Comply? Small Businesses and Residential Properties

One of the most common questions we hear is: “Do ada compliant ramp specifications apply to my business or my home?” The answer isn’t always straightforward, but here’s what you need to know.

All businesses serving the public must comply with ADA requirements, regardless of size. If your business is open to the public – whether it’s a restaurant, retail store, office building, medical facility, hotel, or movie theater – you’re required to provide accessible entry. This often means installing or maintaining ADA-compliant ramps.

Don’t think small businesses get a free pass. The ADA doesn’t have a “small business exemption.” Whether you’re running a massive department store or a cozy café, if customers visit your location, accessibility is required. Even home-based businesses that serve customers at the residence must comply. The goal is ensuring people with disabilities have equal access to goods and services, and non-compliance can lead to costly penalties and lawsuits.

Residential properties follow different rules. Generally, the ADA doesn’t apply to private homes unless they also serve as a place of public accommodation (like that home-based business we mentioned). So if you’re building a ramp for your private home that isn’t open to the public, federal ADA guidelines aren’t legally mandatory.

However, we strongly recommend following ADA guidelines for residential ramps whenever possible. Why? Because these standards are designed for safety and usability. A ramp that’s too steep or too narrow can be dangerous for anyone, especially individuals using wheelchairs, walkers, or those with temporary mobility issues.

Many states and local municipalities here in Florida also have their own building codes that may specify ramp requirements for residential properties. These can sometimes differ from or add to federal ADA standards, so always check with your local municipality for required permits and specific building codes before building an access ramp.

For more guidance on ensuring your property meets accessibility standards, visit our comprehensive guide on How To Be ADA Compliant.

Frequently Asked Questions about ADA Ramp Compliance

We’ve covered a lot of ground regarding ada compliant ramp specifications. Here are some of the most frequently asked questions we encounter, distilled for clarity and peace of mind.

What materials can be used for an ADA-compliant ramp surface?

The beauty of ada compliant ramp specifications is that they focus on performance, not specific materials. Your ramp surface simply needs to be firm, stable, and slip-resistant in all weather conditions—whether it’s a sunny Florida morning or during one of our famous afternoon thunderstorms.

Concrete remains the most popular choice, and for good reason. It’s incredibly durable, naturally stable, and can easily be given a slip-resistant finish with a simple broom texture. Asphalt works well too, especially for longer outdoor ramps, and can be textured for better grip.

Wood can certainly work, but it requires more attention to detail. You’ll need to choose slip-resistant decking materials and stay on top of maintenance to prevent warping or rot that could create dangerous trip hazards. Metal is often used for modular ramps, but it must have a non-slip finish like textured plates or grating—nobody wants to slip on wet metal!

Here’s a crucial detail that catches many people off guard: any openings in your ramp surface must be small enough that a 1/2 inch sphere cannot pass through them. This prevents small wheels, crutch tips, or cane tips from getting caught, which can cause serious falls.

At Florida Sidewalk Solutions, we often see how even the best ramp materials can develop problems over time. Our patented concrete cutting technology helps maintain those perfectly level surfaces around ramp landings and approaches, ensuring your concrete stays compliant and safe.

Are stairs required if a building has an ADA-compliant ramp?

This is one of those questions that surprises people with its simplicity. No, stairs are not required by the ADA if you already have a compliant ramp. The whole point of the ADA is ensuring accessibility, and a properly designed ramp accomplishes exactly that.

But here’s the interesting part—you’ll almost always see stairs alongside ramps anyway. Why? Because not everyone finds ramps easier to use. For someone with certain heart conditions or limited stamina, navigating a long ramp can actually be more challenging than taking stairs. Some people simply prefer stairs for shorter distances.

It’s really about giving people choices. The ramp ensures everyone can access the building, while stairs provide an alternative for those who prefer them. Think of it as the difference between meeting minimum requirements and creating a truly welcoming environment.

What is the difference between a handrail and a guardrail?

People mix these up all the time, but they serve completely different purposes in ada compliant ramp specifications. Think of it this way: one helps you travel, the other keeps you safe.

A handrail is your traveling companion. It’s designed to be gripped for support, balance, and guidance as you move up or down the ramp. Handrails sit at a comfortable 34 to 38 inches high—perfect for most people to reach naturally. They need specific grip sizes, proper clearance from walls, and smooth surfaces so your hand can glide along comfortably without catching on anything.

A guardrail, on the other hand, is your safety net. It’s a much taller barrier—at least 42 inches high—designed to prevent people from accidentally falling over the side of a ramp, especially where there’s a significant drop-off. Guardrails are built tough to withstand considerable force and often include closely spaced balusters (no more than 4 inches apart) to prevent small children from slipping through.

Many ramps have both: handrails for support along your path of travel, and guardrails along the edges to prevent falls. It’s like having both a helpful guide and a protective barrier working together to keep everyone safe.

Conclusion: Ensuring Safety and Compliance on Your Walkways

Understanding and implementing ada compliant ramp specifications goes far beyond simply checking boxes to avoid legal trouble. It’s really about creating spaces where everyone—regardless of their mobility—can move safely and confidently. When you think about it, accessibility benefits everyone: the parent pushing a stroller, the delivery person wheeling a dolly, or your neighbor recovering from knee surgery.

Every specification we’ve covered matters deeply. That precise 1:12 slope isn’t arbitrary—it’s the difference between someone being able to steer independently or needing assistance. The 36-inch width requirement ensures there’s room to maneuver safely. Those 60-inch landings provide crucial rest stops and turning space. Even the handrail height of 34-38 inches was carefully chosen to work for the widest range of users possible.

But here’s something many property managers don’t realize: even perfectly built ramps can become non-compliant over time. Florida’s climate, with its heat, humidity, and seasonal weather changes, causes concrete to shift and settle. What starts as a smooth transition from sidewalk to ramp can gradually develop lips, cracks, and uneven surfaces that create dangerous trip hazards.

These seemingly small changes pose serious risks, especially for people using wheelchairs, walkers, or canes. A quarter-inch lip at a ramp landing might seem minor, but it can stop a wheelchair dead in its tracks or catch the tip of a cane, leading to falls and injuries.

This is where Florida Sidewalk Solutions makes a real difference. We specialize in repairing these trip hazards on ramp landings and walkway approaches using our patented concrete cutting technology. Instead of the expensive, disruptive process of tearing out and replacing concrete, our method precisely cuts and levels the surface to eliminate hazards while maintaining full ADA compliance.

Our approach is not only more effective than traditional methods—it’s also significantly less expensive and causes minimal disruption to your property. We understand that maintaining accessibility shouldn’t break your budget or shut down your facility for days.

By staying proactive about these maintenance issues, you’re doing more than protecting yourself from liability. You’re demonstrating genuine care for everyone who visits your property, creating an environment where accessibility is a priority, not an afterthought.

Learn more about our ADA-compliant sidewalk trip hazard repair services.