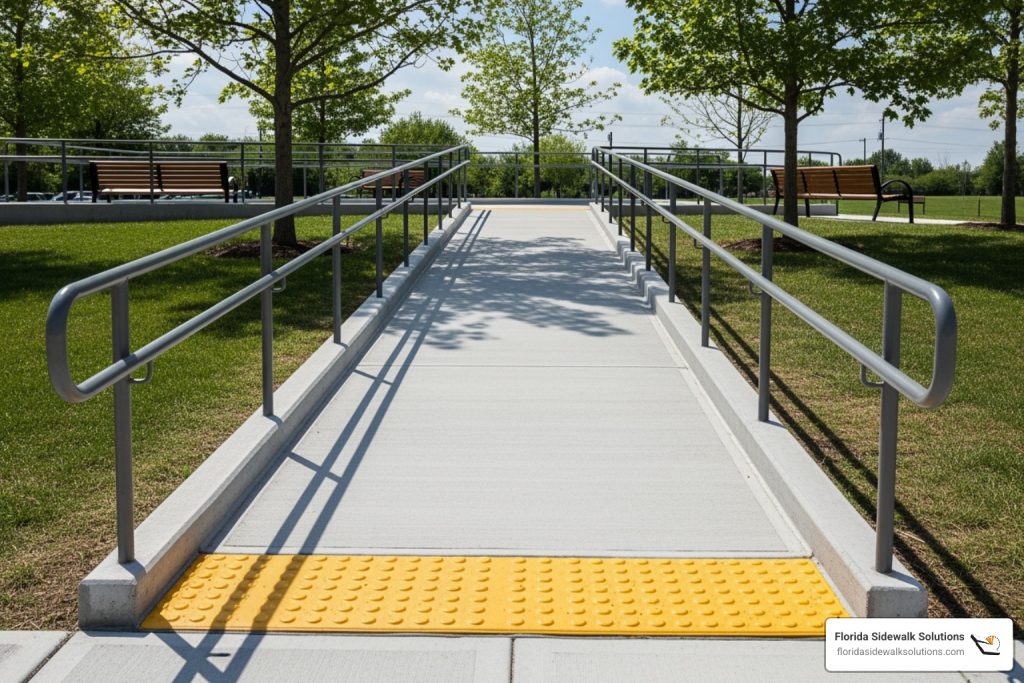

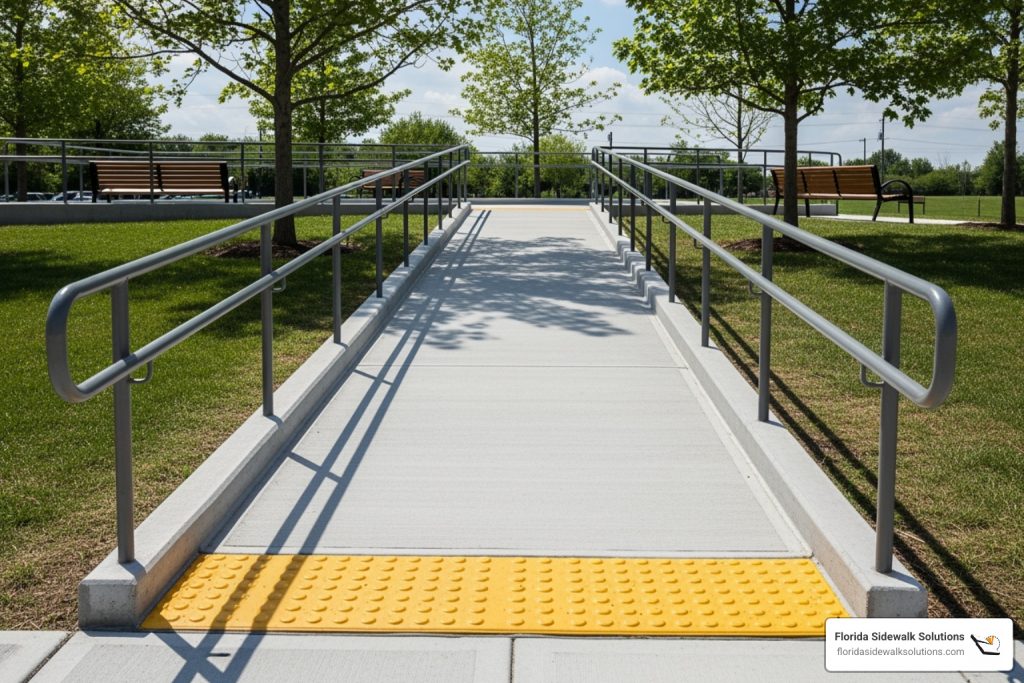

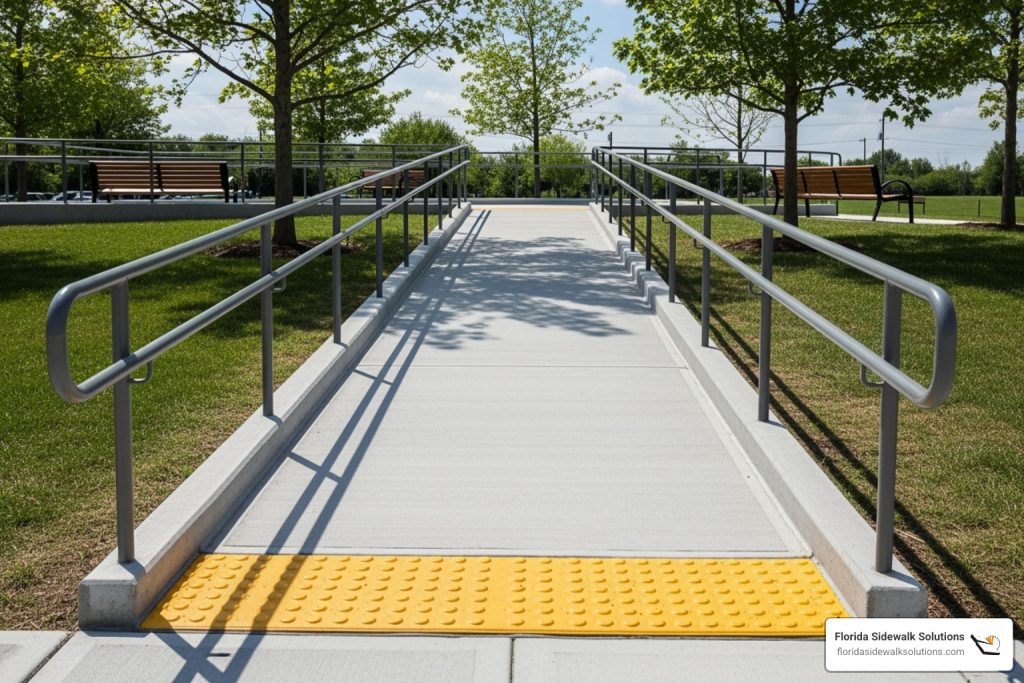

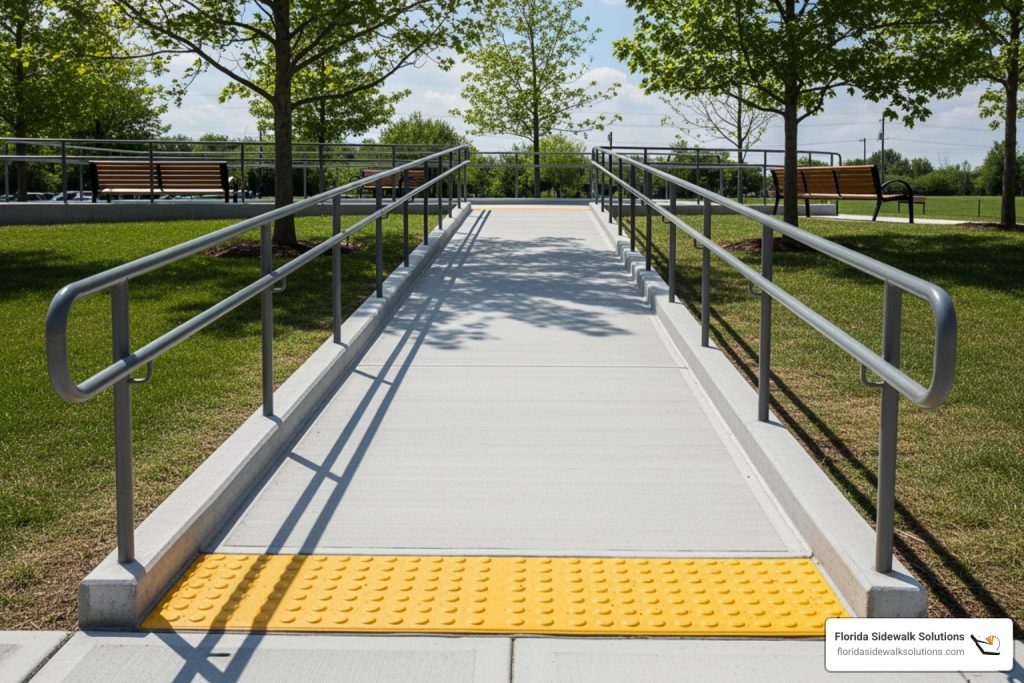

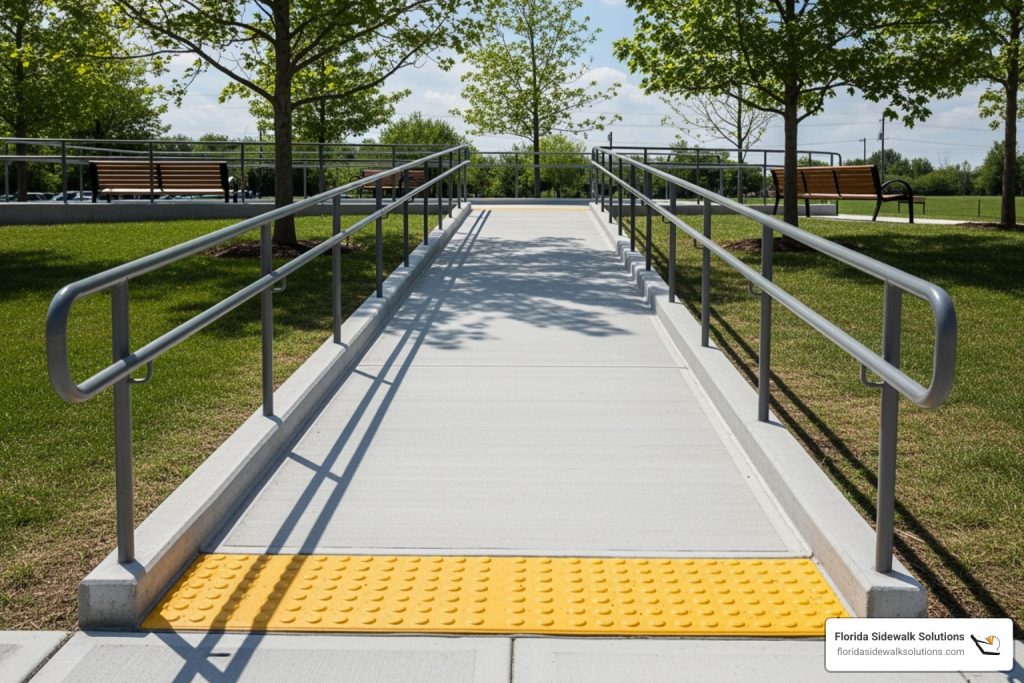

When it comes to ensuring accessibility, concrete handicap ramp installations are essential for ADA compliance. These ramps help remove barriers and provide safe passage for everyone. To address the search intent quickly:

- ADA Compliance: It’s mandatory for public accommodations.

- Concrete Ramps: Offer durability and low maintenance.

- Accessibility: Key for safe and easy access to buildings.

Incorporating ADA guidelines, concrete handicap ramps make spaces accessible for people with disabilities. They help cities meet legal requirements while also creating inclusive environments. These ramps are not just a matter of compliance; they are vital for public safety and accessibility.

For cities like Davie and Fort Lauderdale in Florida, properly designed concrete ramps ensure seamless navigation throughout urban infrastructures, supporting those with mobility challenges.

Understanding ADA Guidelines for Ramps

To create a truly accessible environment, ADA guidelines for ramps are crucial. These guidelines ensure that ramps are safe and usable for everyone, especially those with mobility challenges.

Slope and Rise Requirements

The slope of a ramp is a critical factor in its design. The ADA sets a maximum slope of 1:12, meaning for every inch of vertical rise, the ramp should be at least 12 inches long. This ensures that ramps are not too steep, making them easier to steer for wheelchair users and others with mobility aids.

- Running Slope: The incline of the ramp in the direction of travel must not exceed the 1:12 ratio. This is crucial for maintaining accessibility without requiring excessive effort to ascend.

- Cross Slope: This is the slope perpendicular to the running slope and must not exceed 1:48. Keeping the cross slope minimal ensures stability and safety while traversing the ramp.

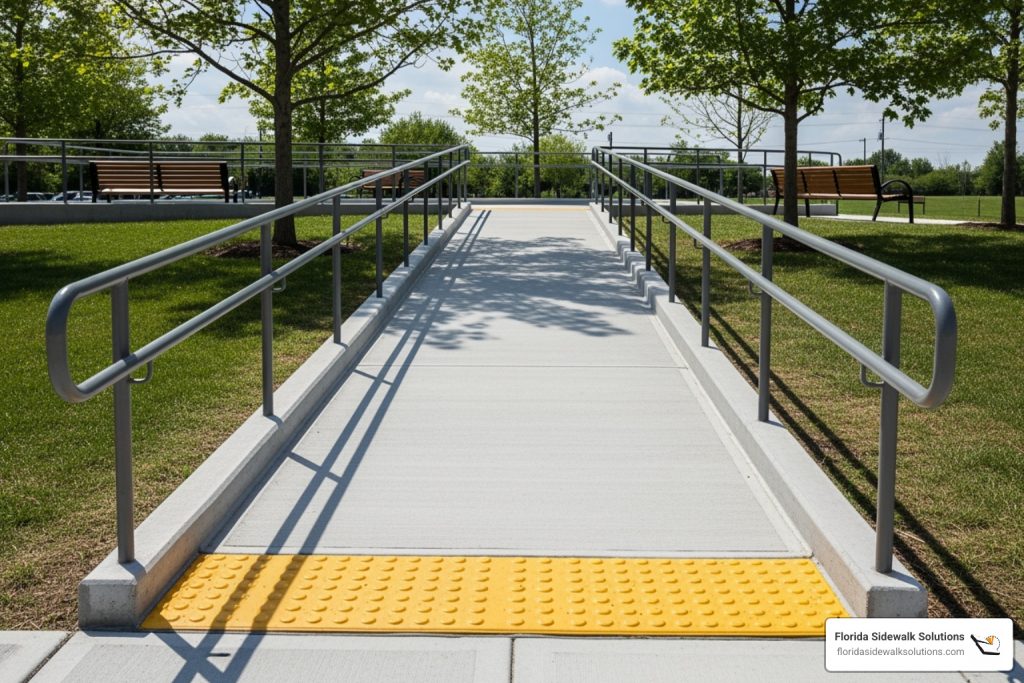

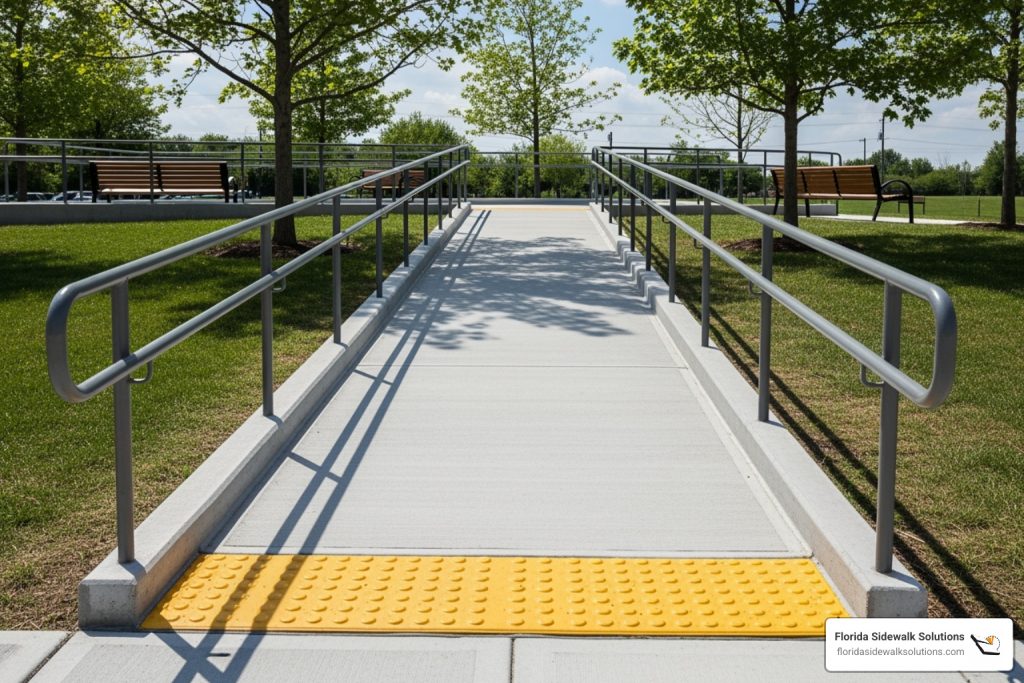

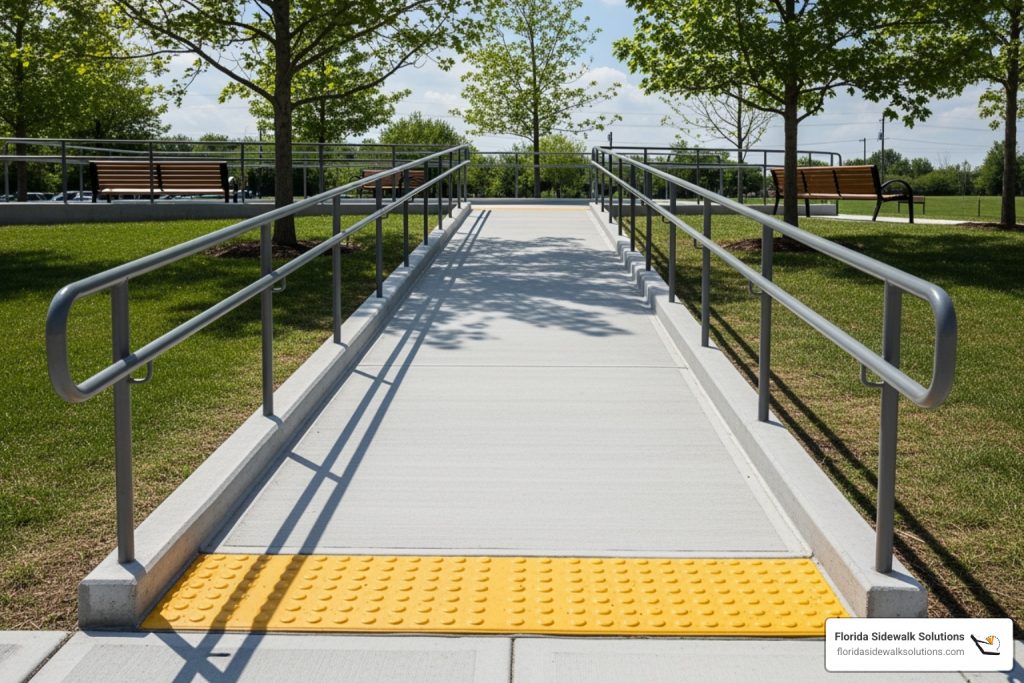

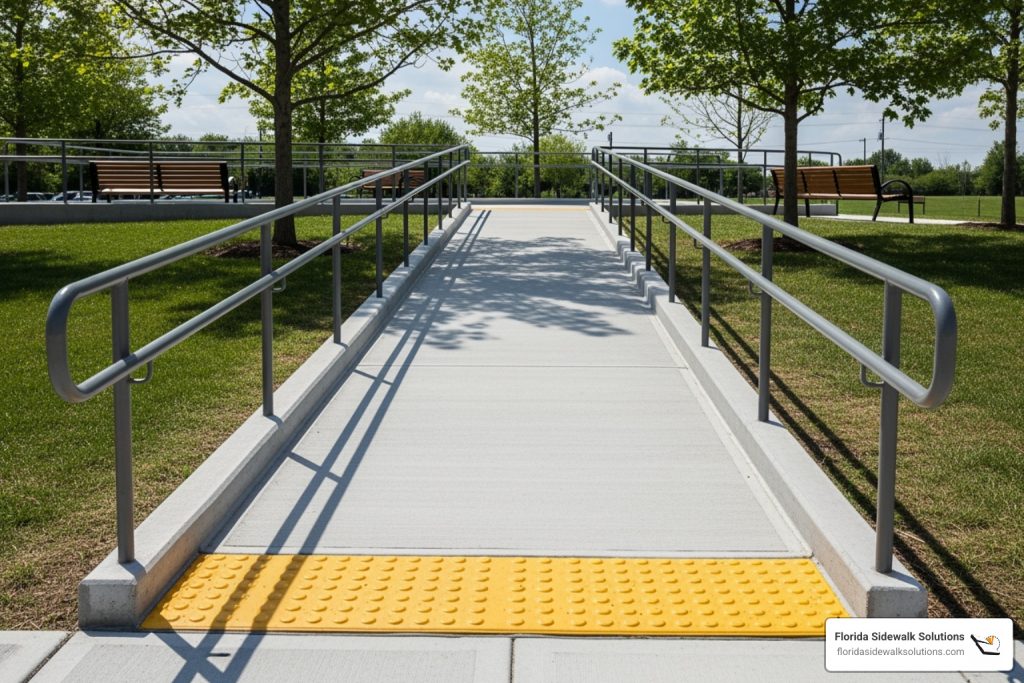

Width and Surface Specifications

The minimum width for ADA-compliant ramps is 36 inches. This width provides enough space for a wheelchair to pass comfortably and safely. However, in high-traffic areas, a wider ramp might be necessary to accommodate two-way traffic.

- Slip-Resistant Surfaces: Ramps must have surfaces that prevent slipping, especially in wet conditions. This is vital for the safety of users, reducing the risk of accidents.

- Edge Protection: Ramps should have edge protection to prevent wheelchairs or other mobility aids from slipping off. This can be achieved with curbs, walls, or extended surfaces on the sides of the ramp.

By adhering to these ADA standards, ramps not only meet legal requirements but also improve the safety and usability of public and private spaces. Concrete handicap ramps designed with these guidelines ensure that everyone, regardless of mobility, can access facilities comfortably and safely.

Concrete Handicap Ramp: Key Considerations

When considering the installation of a concrete handicap ramp, there are several key factors to weigh, including durability, cost, and installation process. Let’s explore why concrete ramps are often the go-to choice for many facilities.

Benefits of Concrete Ramps

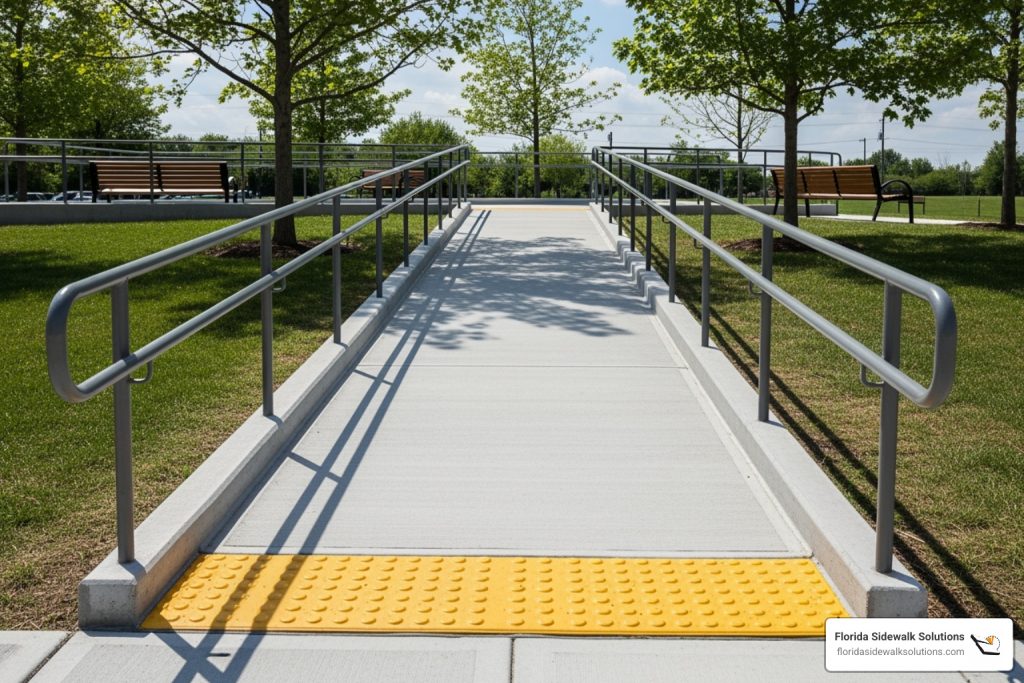

Concrete ramps offer a permanent solution for accessibility needs. Unlike temporary or modular options, concrete ramps are built to last, providing a stable and reliable path for years to come.

- Durability: Concrete is known for its strength and resilience. It can withstand heavy use and harsh weather conditions without deteriorating. This makes it an excellent choice for outdoor environments where exposure to the elements is a concern.

- Weather Resistance: Concrete ramps are not only durable but also resistant to weather changes. They hold up well against rain, snow, and extreme temperatures, ensuring that the ramp remains safe and functional at all times.

- Low Maintenance: Once installed, concrete ramps require minimal upkeep. Their robust nature means fewer repairs and less frequent maintenance, saving time and money in the long run.

Installation Process

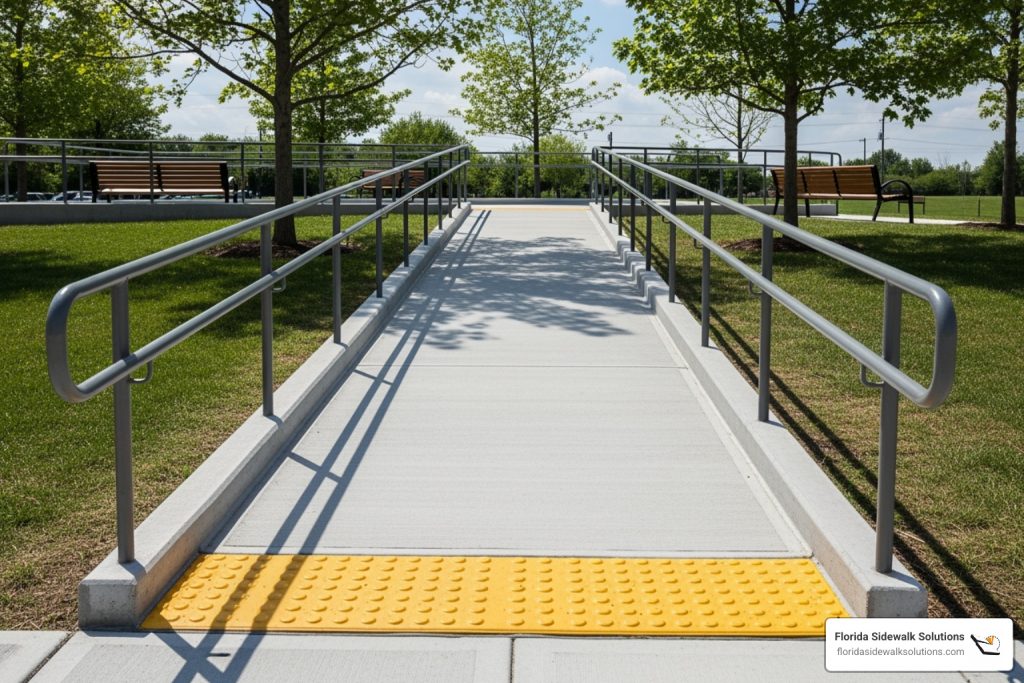

Installing a concrete ramp involves several crucial steps, each of which must be executed with precision to ensure compliance with ADA guidelines and to maximize the ramp’s longevity.

- Site Preparation: Before construction begins, the site must be properly prepared. This includes clearing the area of debris, leveling the ground, and ensuring proper drainage to prevent water accumulation on the ramp.

- Concrete Pouring: The next step is pouring the concrete. This process must be done carefully to avoid air pockets and ensure a smooth, even surface. The concrete mix should be suitable for the anticipated load and environmental conditions.

- Curing Time: After pouring, the concrete needs time to cure. This is a critical phase where the concrete gains strength. Typically, a curing period of at least 7 days is recommended, though full strength is usually achieved after 28 days.

By following these steps, you can ensure the successful installation of a concrete handicap ramp that is both functional and compliant with ADA standards. This investment not only improves accessibility but also adds long-term value to any property.

Alternatives to Concrete Handicap Ramps

While concrete handicap ramps are a popular choice due to their durability and permanence, there are other options worth considering that offer flexibility and ease of installation. Let’s explore alternatives like modular ramps, precast ramps, and ADA compliant sidewalks.

Precast Concrete Ramps

Precast concrete ramps offer a blend of the benefits of traditional concrete with the advantage of quick installation. These ramps are manufactured in a controlled environment and then transported to the site, which means they can be installed in hours rather than days.

- Precast Benefits: One of the biggest advantages is the controlled manufacturing process. This ensures high-quality finishes and reduces the risk of defects such as cracking or uneven surfaces. The ramps are also relocatable, making them a flexible option for businesses that may need to move or adjust their accessibility solutions.

- Quick Installation: Because they are precast, these ramps can be set up quickly, minimizing downtime and disruption. This is ideal for businesses that need to maintain access and safety during renovations or new constructions.

- Anti-Skid Texture: Safety is a top priority, and precast ramps come with an anti-skid texture cast into their surface. This feature improves traction and reduces the risk of slips and falls, especially in wet or icy conditions.

Modular Ramps

Modular ramps are another alternative that provides flexibility and ease of use. These ramps can be assembled and disassembled as needed, making them suitable for temporary installations or locations where space is limited.

- Portability: Modular ramps are typically made from materials like aluminum or steel, making them lightweight and easy to move. This portability is beneficial for events or temporary setups where a permanent ramp is not feasible.

- Customizable Configurations: These ramps can be configured to fit various spaces and requirements. With different lengths, widths, and platform options, modular ramps provide a custom solution without the need for extensive construction work.

ADA Compliant Sidewalks

In some cases, it might be possible to create an ADA compliant sidewalk instead of a ramp. This is a great option if the site allows for a gradual slope that meets ADA guidelines.

- Space Considerations: Sidewalks require more space due to their gentle slopes but can be a cost-effective solution as they often require fewer materials and less labor to install.

- No Handrails Needed: If the slope is gentle enough, handrails may not be necessary, which can reduce costs. However, it is crucial to ensure that the slope and surface meet all ADA requirements to maintain accessibility.

By exploring these alternatives, you can find the right balance between functionality, cost, and installation time for your accessibility needs. Next, we’ll address some frequently asked questions about concrete handicap ramps to further guide your decision-making process.

Frequently Asked Questions about Concrete Handicap Ramps

What is the cost of a concrete handicap ramp?

The average cost of a concrete handicap ramp can vary widely, typically ranging from $1,000 to $3,000 or more. Several factors influence this cost, including:

- Ramp Size and Length: Longer ramps with greater rise will naturally cost more due to the increased amount of materials and labor required.

- Site Conditions: If the installation site is difficult to access or requires significant preparation, costs may increase. For example, uneven terrain might necessitate additional grading or leveling.

- Design Features: Adding features like handrails, non-slip surfaces, or decorative finishes can also affect the total cost.

- Local Labor Rates: Labor costs can vary significantly depending on the region, so consider local rates when budgeting for your project.

How to build a concrete handicap ramp?

Building a concrete handicap ramp involves several key steps, and while it might be tempting to try a DIY approach, it’s often best left to professionals to ensure ADA compliance.

- Site Preparation: Clear the area of debris and level the ground. This step is crucial for ensuring a stable foundation.

- Frame Construction: Build a wooden frame to outline the ramp. This frame will hold the concrete in place as it sets.

- Pouring Concrete: Pour the concrete into the frame, ensuring an even distribution. Use a trowel to smooth the surface and create a slight texture for slip resistance.

- Curing Time: Allow the concrete to cure for at least 24 to 48 hours before removing the frame. This curing period is essential for the ramp’s durability and strength.

- Finishing Touches: Add any additional features, such as handrails or edge protection, to improve safety and accessibility.

While some may consider a DIY approach, ADA compliance is crucial. Errors in slope, width, or surface finish can result in a non-compliant ramp, leading to potential safety hazards and legal issues.

Can I avoid installing a ramp?

In some situations, it might be possible to avoid installing a ramp by exploring alternative solutions. For example, if the site allows, creating an ADA compliant sidewalk with a gentle slope may be a viable option. This can eliminate the need for a ramp and the associated costs, like handrails.

However, if a ramp is necessary to comply with ADA guidelines, it’s crucial to ensure that all accessibility standards are met. Non-compliance can lead to penalties and restrict access for individuals with disabilities.

By understanding the costs, installation process, and potential alternatives, you can make informed decisions about the best accessibility solutions for your property.

Conclusion

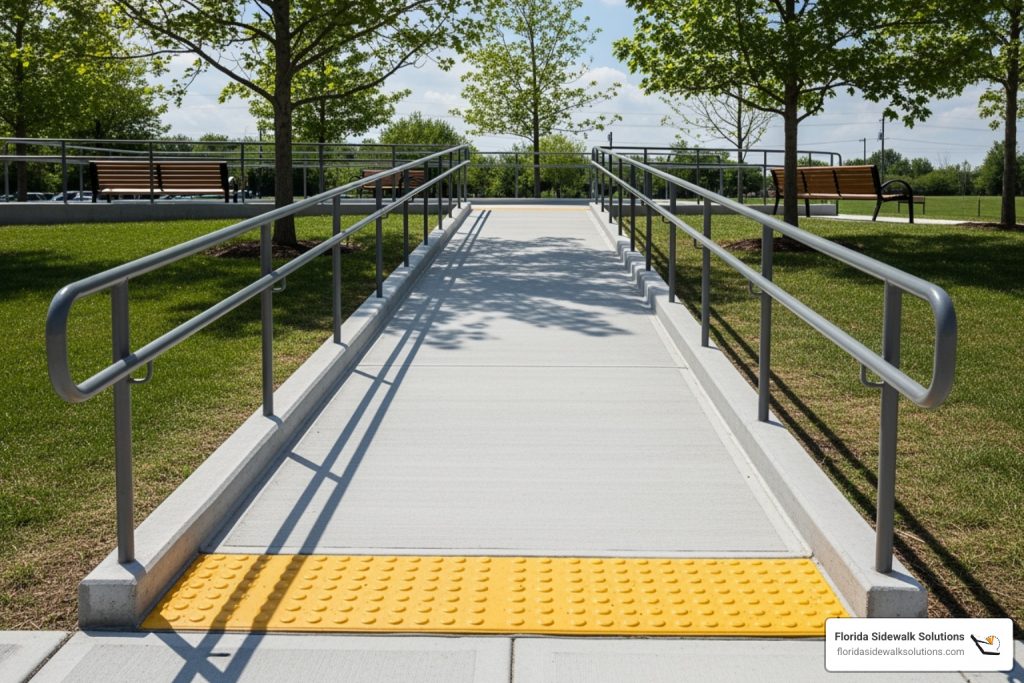

At Florida Sidewalk Solutions, we are dedicated to providing top-notch accessibility solutions that ensure compliance with the ADA guidelines. Our expertise in trip hazard removal and concrete repair positions us as a leader in creating safe and accessible pathways for everyone.

ADA compliance is not just a legal requirement; it’s a commitment to inclusivity and accessibility. By ensuring that your property has the necessary features, like a well-constructed concrete handicap ramp, you contribute to a more inclusive environment where people with disabilities can steer freely and safely.

Our innovative approaches, such as using patented technology for concrete repairs, allow us to offer cost-effective and efficient solutions. Whether you’re looking to repair an existing ramp or install a new one, our team is ready to assist with expert guidance and high-quality service.

If you’re considering options beyond traditional ramps, such as precast concrete ramps or ADA-compliant sidewalks, we can help you explore these alternatives. These solutions can often provide quicker installation and lower maintenance, ensuring long-term satisfaction.

For more information on our services and to explore how we can help make your property more accessible, visit our Handicap Ramp Repair in Florida page. We look forward to working with you to improve accessibility and create a safer environment for all.

Find us on: Facebook | LinkedIn | Yelp