Why Broken Concrete Walkways Are More Than Just an Eyesore

A damaged concrete walkway isn’t just unsightly—it’s a serious safety hazard that can expose you to significant liability. The answer to how to repair broken concrete walkway damage hinges on identifying the root cause. While minor surface cracks may seem trivial, the most dangerous issue is uneven slabs that create trip hazards. These require professional leveling to ensure ADA compliance and prevent costly trip-and-fall accidents.

A damaged concrete walkway isn’t just unsightly – it’s a serious safety hazard that can expose you to significant liability. According to federal law, broken or uneven sidewalks must be repaired as soon as possible to prevent costly trip and fall accidents.

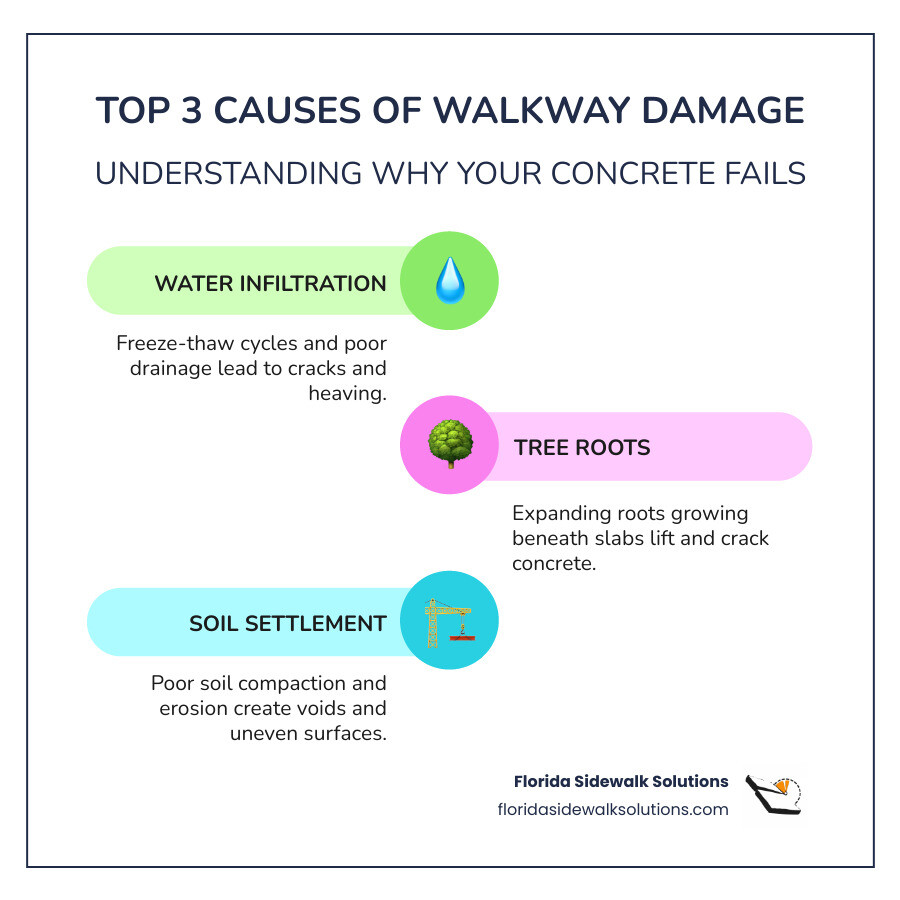

The most common causes of walkway damage include:

- Water infiltration – Freeze-thaw cycles cause concrete to crack and heave

- Tree root growth – Expanding roots lift and crack concrete slabs

- Soil settlement – Poor drainage and erosion create voids under walkways

- Heavy traffic – Repeated loading weakens concrete over time

For property owners and municipal maintenance managers, the challenge is finding repair solutions that are both cost-effective and compliant with ADA requirements. Traditional methods like grinding or full replacement can be expensive and disruptive to pedestrian traffic.

The key is understanding that not all concrete damage is the same. While a small surface crack is a cosmetic issue, significant elevation changes between slabs are a liability that requires specialized equipment and expertise to create safe, compliant surfaces.

Important how to repair broken concrete walkway terms:

First, Assess the Damage: Should You Repair or Replace?

Before deciding on a course of action, take a step back and play detective. Understanding how to repair broken concrete walkway damage starts with properly assessing what you’re dealing with. This isn’t just about saving moneywe—it’s about choosing the right solution that will actually keep people safe.

Think of it like going to the doctor. A bandage might fix a small cut, but you wouldn’t use the same treatment for a broken bone. The same logic applies to concrete walkways.

Cosmetic vs. Safety Issues

Surface-level issues like hairline cracks or small chips (“spalling”) might make your walkway look tired, but they are fundamentally different from structural problems. While you can find information on sidewalk crack repair, it’s crucial to recognize when the problem goes beyond cosmetics.

When you see wide cracks, crumbling edges, or signs that the ground beneath is failing, you’re likely looking at a deeper issue. These problems often lead to the biggest danger of all: uneven slabs.

The Biggest Danger: Uneven Slabs and Trip Hazards

Here’s where things get serious—and expensive if someone gets hurt. Heaved or sunken slabs and height differences between sections create genuine trip hazards. These problems are often caused by tree roots pushing up from below or soil erosion causing sections to settle unevenly. You can review the official federal ADA Standards for Accessible Design to understand exactly how these height differences are regulated.

This isn’t just about looks anymore; it’s about liability. According to ADA compliance rules, any vertical change over 1/4 inch is a potential trip hazard that must be beveled. If the height difference exceeds 1/2 inch, you need a proper ramp.

Here’s the key point: you can’t just patch your way out of this problem. The underlying unevenness must be addressed through professional leveling, not surface repair. Uneven sidewalk repairs require specialized techniques to create safe, compliant surfaces.

The bottom line? While minor cosmetic issues can be monitored, trip hazards need immediate professional attention. Your insurance company—and your conscience—will thank you for taking the dangerous stuff seriously.

How to Repair a Broken Concrete Walkway: Choosing Your Method

Now that we’ve assessed the damage, it’s time to choose the right repair. The correct approach to how to repair broken concrete walkway depends entirely on whether you’re dealing with a simple cosmetic flaw or a serious safety hazard.

Addressing Trip Hazards: The Real Problem

Here’s where things get serious. When you’re dealing with uneven slabs that create trip hazards, simply patching the surface won’t solve the underlying safety problem. It’s like putting a bandage on a broken bone—it might cover the issue, but the real danger remains.

Traditional repair methods for uneven concrete include grinding down the higher section or full replacement. While these approaches can work, they often create their own problems. Grinding creates clouds of dust, can be incredibly loud, and often leaves an unsightly, discolored patch that screams “repair job.” Full replacement is even more costly and disruptive.

More importantly, this type of damage requires leveling, not just patching. According to ADA guidelines, any height difference over 1/4 inch between concrete sections is considered a trip hazard and must be addressed with proper ramping. This isn’t just about aesthetics—it’s about safety and legal compliance. Our uneven sidewalk repairs page explains these requirements in detail.

The Florida Sidewalk Solutions Method: Precision Concrete Cutting

When it comes to eliminating trip hazards, there’s a better way than the messy, expensive traditional methods. Our specialized approach uses patented precision cutting technology to create smooth, ADA-compliant transitions directly in your existing concrete.

Instead of trying to raise sunken slabs or grind away liftd ones, we focus on removing the dangerous “lip” that creates the trip hazard. Our precision saw cuts a smooth, sloped transition that eliminates the height difference while maintaining the structural integrity of your walkway.

Why does this method work so much better? First, it’s incredibly precise – our patented technology creates consistent, smooth slopes that seamlessly blend with your existing walkway. There’s no guesswork or variable results like you get with grinding or slab raising.

Cost-wise, it’s a game-changer. Because we work with your existing concrete rather than removing and replacing entire sections, our method typically costs significantly less than full replacement (which averages over $1,300 per slab) while being more reliable than temporary fixes.

The process is also remarkably clean and efficient. Unlike grinding that creates clouds of dust or concrete pouring that takes days to cure, our precision cutting method is relatively quiet and dust-free. Most repairs can be completed quickly, meaning minimal disruption to foot traffic or your daily routine.

Most importantly, our method ensures ADA compliance by creating proper ramping that meets all accessibility guidelines. This isn’t just about avoiding trip hazards – it’s about creating walkways that are safe and accessible for everyone, including those with mobility challenges.

You can learn more about this innovative approach on our level concrete walkways with FSS page, or explore our comprehensive sidewalk trip hazard repair services.

When you’re facing the question of how to repair broken concrete walkway with significant safety hazards, precision cutting offers the perfect balance of effectiveness, economy, and long-term durability.

Prevention, Permits, and Responsibility

Congratulations! You’ve tackled your walkway repair, but now comes the equally important part: keeping it in great shape for years to come. Understanding prevention strategies and your legal responsibilities isn’t just about maintaining curb appeal – it’s about protecting your investment and avoiding future liability issues.

How to Prevent Future Concrete Walkway Cracks

The secret to long-lasting concrete isn’t really a secret at all – it’s all about being proactive. Think of your walkway like your car: regular maintenance prevents major breakdowns down the road.

Water management is your concrete’s best friend (when controlled) and worst enemy (when it’s not). Make sure your landscape slopes away from your walkway, directing rainwater where it belongs – away from your concrete. That innocent-looking puddle might seem harmless, but water seeping underneath your walkway can wash away soil and create the exact conditions that lead to uneven slabs and trip hazards.

Sealing your concrete every 2-3 years creates a protective barrier against moisture, chemicals, and those brutal freeze-thaw cycles. It’s like sunscreen for your sidewalk – a small investment that prevents much bigger problems later. The cost of a concrete sealer is minimal compared to how to repair broken concrete walkway issues that develop when water infiltrates the surface.

Tree roots are beautiful in your yard but troublesome under your walkway. If you have large trees nearby, managing tree root growth becomes crucial. Consider consulting an arborist about root barriers before roots decide to redecorate your walkway with their own unique brand of “natural art.”

During winter months, avoid harsh de-icing salts that can chemically attack concrete surfaces. Sand or pet-friendly alternatives work just as well without the long-term damage. Your concrete (and your pets’ paws) will thank you.

Finally, keep those control joints clean – those deliberate lines cut into your concrete aren’t just decorative. They’re designed to control where cracks occur, so keeping them free of debris and properly sealed helps your walkway age gracefully. Concrete Repair with FSS can provide expert guidance on maintenance strategies specific to your situation.

Who is Responsible for Sidewalk Repair?

Here’s where things get interesting (and sometimes frustrating). The question of who pays for sidewalk repairs isn’t answered the same way everywhere, and assuming can lead to some unpleasant surprises.

In most residential areas, homeowners are responsible for maintaining the sidewalk adjacent to their property, even though it’s technically public property. This responsibility often includes everything from minor crack repairs to addressing major trip hazards. Some cities, like New York, have very clear ordinances making homeowners explicitly responsible for sidewalk maintenance and repairs.

However, some municipalities take full responsibility for sidewalk maintenance, while others operate cost-sharing programs where the city splits repair costs with homeowners – sometimes 50/50. In gated communities or planned developments, your Homeowner’s Association (HOA) might handle all sidewalk maintenance as part of your monthly fees.

The stakes are higher than just repair costs. Liability for trip and fall accidents can fall squarely on the property owner’s shoulders, making proper maintenance not just a civic duty but a financial necessity.

Before you start planning any major repairs, make that call to your local Public Works department or check with your HOA. Understanding your responsibilities upfront can save you from unexpected bills and help you take advantage of any available cost-sharing programs.

Do I Need a Permit for Walkway Repair?

The permit question is like asking “how long is a piece of string?” – it depends entirely on your local regulations and the scope of your project.

Minor repairs like filling small cracks or patching chips are typically considered routine maintenance and don’t require permits. You’re basically maintaining what’s already there, not changing the structure or function of the walkway.

Major replacements or structural changes, especially work in the public right-of-way, often require permits. This includes full slab replacement, significant grading changes, or any work that could affect drainage patterns or public safety. The permit process ensures that repairs meet local codes and safety standards.

When work involves addressing trip hazards or creating ADA-compliant surfaces, permits become even more likely. The good news is that professional services like Florida Sidewalk Solutions understand local permit requirements and can guide you through the process when necessary.

Always check with your local building department before starting any significant project. A quick phone call or website visit can save you from fines, delays, or the nightmare of having to redo work that doesn’t meet code requirements. Trust me, it’s much easier to get the permit first than to explain to an inspector why you didn’t think you needed one!

Frequently Asked Questions about Walkway Repair

We get a lot of questions about concrete walkways, and for good reason! They take a beating from foot traffic, weather, and sometimes even the very ground they sit on. After years of helping homeowners understand how to repair broken concrete walkway issues, we’ve noticed the same questions come up again and again. Let’s tackle the big ones.

How do you fix a sunken concrete walkway?

A sunken concrete walkway isn’t just unsightly—it’s a genuine safety concern that can leave you liable for injuries. When one slab settles lower than its neighbor, you’ve got a trip hazard that needs immediate attention.

While some methods involve attempting to lift the slab or the expensive route of tearing everything out and starting over, these approaches have significant drawbacks. Lifting can be unpredictable and may fail over time, while full replacement is costly and disruptive.

Florida Sidewalk Solutions takes a smarter approach. Instead of fighting the settled slab, we work with what’s already there. Our precision concrete cutting technology removes the dangerous “lip” created by the height difference. We cut a smooth, sloped transition directly into the higher slab, creating an ADA-compliant ramp that eliminates the trip hazard entirely.

This method is brilliant because it’s clean, precise, and permanent. No messy demolition and no wondering if the repair will hold up. Learn more about our approach to raising concrete walkway solutions.

What is the best material to fill large cracks in a concrete walkway?

While filling a large crack might seem like a solution, it’s often just a temporary cosmetic fix. Large cracks are typically a symptom of a bigger problem, such as soil settlement or water erosion, which can lead to uneven slabs and dangerous trip hazards.

Instead of just covering up the crack, it’s more effective to address the underlying cause of the damage. If a crack is accompanied by a height difference between slabs, the priority must be to eliminate the trip hazard. Our precision cutting method can resolve the height difference, which is the true safety issue, creating a stable and compliant surface.

How much of a height difference in a sidewalk is a trip hazard?

This is probably the most important question we get, especially when it comes to safety and legal liability. According to the Americans with Disabilities Act (ADA), any vertical change in level over 1/4 inch is considered a potential trip hazard and must be beveled with a slope no steeper than 1:2.

If the height difference is over 1/2 inch, it requires a ramp to meet compliance standards. This isn’t just bureaucratic red tape—these measurements are based on real safety data about what causes people to trip and fall.

Here’s why this matters so much: simply patching over uneven slabs doesn’t solve the underlying problem. You might make the crack look better, but that dangerous height difference is still there, waiting to catch someone’s toe.

This is where the Florida Sidewalk Solutions method really shines. Our precision cutting creates that required beveled transition directly in the existing concrete, ensuring full ADA compliance while eliminating the safety risk. It’s not just about making things look better—it’s about creating genuinely safe walkways that protect both pedestrians and property owners from liability issues.

Your Next Step to a Safe and Beautiful Walkway

You know what? A broken, uneven concrete walkway isn’t one of those problems you can just put off until “someday.” It’s staring you in the face every time you walk out your front door, and more importantly, it’s putting everyone who uses your walkway at risk. We’re talking about real safety concerns here – the kind that can lead to serious injuries and even lawsuits.

After walking through all the different ways how to repair broken concrete walkway damage can occur, one thing becomes crystal clear: not all repairs are created equal. Those small hairline cracks? Grab some concrete filler and make it a weekend project. But when we’re dealing with uneven slabs that create genuine trip hazards, that’s when we need to get serious about finding the right solution.

Here’s the thing about trip hazards – they don’t get better with time. That little lip between concrete slabs might seem manageable now, but it’s a lawsuit waiting to happen. And traditional repair methods? They often fall short of what’s really needed. Grinding creates a mess and leaves unsightly patches. Full replacement costs a fortune and disrupts your entire routine for days.

The Florida Sidewalk Solutions method tackles this problem head-on with a completely different approach. Instead of trying to work around the problem, we solve it directly. Our patented concrete cutting technology creates that smooth, ADA-compliant transition right into the existing concrete. No pumping mysterious materials underneath that might settle again. No dusty grinding that leaves your walkway looking like a patchwork quilt.

What makes our approach so effective is its precision. We’re not guessing or hoping for the best – we’re using specialized equipment designed specifically for this exact problem. The result? A walkway that’s not only safe but actually looks intentional, like it was designed that way from the start.

And let’s be honest about the money side of things. Our method consistently costs less than full replacement while delivering better results than traditional grinding or leveling techniques. You get professional-grade safety and ADA compliance without the professional-grade price tag that usually comes with concrete work.

The peace of mind alone is worth it. No more wincing every time someone walks up to your front door. No more worrying about liability if someone takes a tumble. Just a safe, attractive walkway that you can feel good about.

Ready to get that trip hazard fixed once and for all? Contact a concrete walkway repair company today for a free estimate! Let’s turn that safety concern into a problem solved.