Why Concrete Wheelchair Ramp Repair is Critical for Safety and Compliance

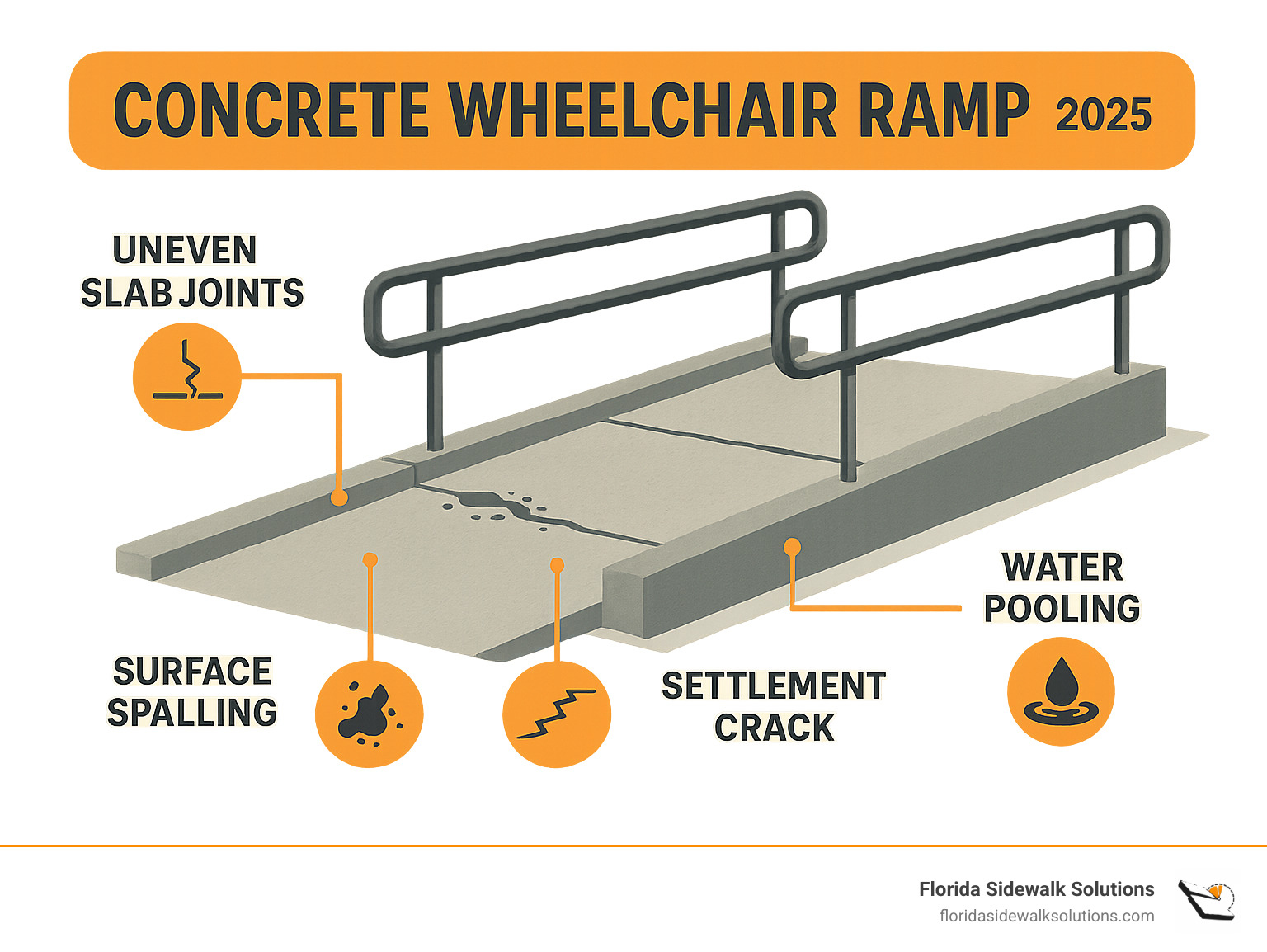

Concrete Wheelchair Ramp Repair is essential for maintaining safe, accessible pathways that comply with ADA standards. Addressing issues like uneven slabs, cracks, or surface deterioration restores safety and prevents dangerous falls without breaking your budget.

Quick Solutions for Common Ramp Issues:

- Uneven slabs & trip hazards: Precision cutting for smooth transitions.

- Cracks & spalling: Targeted repairs based on severity.

- ADA compliance violations: Professional assessment and correction.

- Water pooling: Slope and surface adjustments.

According to the National Safety Council, 32% of all nonfatal injuries in 2019 resulted from falls, making ramp maintenance a critical safety priority. Even a quarter-inch vertical change in surface is considered a trip hazard by ADA standards, putting your organization at risk for liability issues.

The good news is that you don’t always need a full replacement. Modern precision cutting methods can address most ramp trip hazards at 1/10 the cost of traditional approaches, with minimal disruption to pedestrian traffic.

For municipal maintenance managers, this means you can tackle multiple problem areas efficiently while ensuring long-term ADA compliance. The key is understanding when repair makes sense versus when replacement is unavoidable.

Concrete Wheelchair Ramp Repair vocab to learn:

Identifying Common Ramp Damage: What to Look For

For Concrete Wheelchair Ramp Repair, early problem detection saves time and money. Be aware of the most common issues before they become dangerous or expensive.

Common issues include cracks, which expand due to temperature changes and freeze-thaw cycles. A hairline crack can quickly become a significant hazard if ignored.

Spalling, or the flaking of the top concrete layer, is often caused by harsh weather or de-icing chemicals. It creates rough, uneven patches that impede travel.

Perhaps the most dangerous issue is uneven slabs, where one section is higher than the next due to soil settlement or tree roots. This creates a significant barrier for wheelchair users.

Water damage from poor drainage accelerates deterioration. In cold climates, freeze-thaw cycles are especially destructive, as freezing water expands and widens existing cracks.

All of these issues contribute to trip hazards and surface deterioration that make ramps unsafe and non-compliant. The key is catching them before they become major accessibility barriers.

Why Even Small Flaws Matter for Safety and Accessibility

According to ADA compliance standards, a vertical change of just a quarter-inch is considered a trip hazard. This small bump can stop a wheelchair or cause a fall.

With 32% of all nonfatal injuries in 2019 resulting from falls, even minor ramp defects pose serious fall risks. An unexpected lip or crack can cause a wheelchair user to lose control or an elderly pedestrian to fall.

Property owners face significant liability issues from poorly maintained ramps. Proactive Concrete Wheelchair Ramp Repair is far more cost-effective than injury lawsuits.

Beyond legalities, defective ramps create a frustrating wheelchair user experience and compromise safe stroller access. Every person deserves to steer public spaces with dignity and confidence.

The bottom line? Small flaws create big problems for the people who need these ramps most.

Performing a Ramp Safety Audit

Before starting Concrete Wheelchair Ramp Repair, a thorough safety audit is necessary to identify all problem areas.

- Walk the ramp and inspect uneven joints. Measure any vertical displacement; over a quarter-inch is an ADA violation.

- Measure crack width and depth. Address any crack wider than a quarter-inch or deep enough to catch a caster. Check for crumbling edges.

- Assess water pooling by looking for stains or standing water, which indicate poor drainage and create slippery conditions.

- Test handrail stability. Ensure they are firmly anchored, as loose handrails are a safety hazard.

This systematic approach ensures you catch every issue. For more detailed guidance on ramp specifications, check out our comprehensive guide on Concrete Handicap Ramp installations and repairs.

Evaluating Your Concrete Wheelchair Ramp Repair Options

After auditing your ramp, the next step in Concrete Wheelchair Ramp Repair is evaluating repair options. The best approach depends on the damage, your budget, and the need to maintain ADA compliance.

When considering repair methods, we weigh these key factors:

- Cost-effectiveness: The solution must be financially sound both immediately and long-term.

- Durability: The repair must be a lasting solution, not a temporary fix.

- ADA standards: The repair must result in full ADA compliance for a safe pathway.

- Disruption: The process should cause minimal inconvenience to ramp users.

While there are various concrete repair techniques, our focus at Florida Sidewalk Solutions is on tackling the most dangerous ramp issue: trip hazards from uneven concrete.

The Florida Sidewalk Solutions Method: Precision Concrete Cutting

Florida Sidewalk Solutions uses a patented precision concrete cutting technology for Concrete Wheelchair Ramp Repair. This method is highly effective, efficient, and economical for fixing trip hazards and restoring accessibility.

Instead of messy demolition, we use specialized equipment to precisely cut and level uneven slabs and raised joints. This process ensures:

- Targeted Trip Hazard Removal: Our technology pinpoints and corrects specific vertical differences, creating a smooth, gradual transition.

- Smooth Transition: The result is a seamless, beveled edge that eliminates the trip hazard, allowing wheelchairs and pedestrians to pass smoothly.

- Cost-Effective Solution: Our method costs just 1/10 of traditional repair methods like replacement, allowing you to fix more hazards within your budget.

- Minimal Disruption: With no demolition, our process is quick and clean, with less noise and debris, allowing for a fast return to service.

- Long-Term Solution: Precision cutting provides a durable, lasting repair for trip hazards, unlike temporary patches that can fail.

This approach allows property managers to address safety concerns and ensure ADA compliance without the huge investment and headaches of a full ramp replacement. To learn more about how our approach ensures ADA Trip Hazard Repair, check out our dedicated page.

Why Precision Cutting is Superior to Outdated Methods

For Concrete Wheelchair Ramp Repair, our precision cutting method offers clear advantages over outdated techniques in cost, time, and durability.

- Conventional Scabblers and Grinders: These tools often leave a rough, pitted surface that fails to create a truly smooth, ADA-compliant transition.

- Full Removal and Replacement: This is the most disruptive and expensive option. It involves demolition, debris removal, and long curing times, making it overkill for most trip hazards.

Here’s why our precision cutting method for trip hazards is better:

- No Messy Demolition: Our precise process avoids the noise, dust, and debris of jackhammers.

- Faster Completion: With no demolition or curing times, repairs are completed swiftly with minimal disruption.

- More Affordable: By avoiding extensive labor, materials, and disposal fees, our method is significantly more cost-effective.

- Environmentally Friendly: Our approach produces less waste, reducing the carbon footprint compared to replacement.

Our commitment is to provide an effective, economical, and ADA-compliant solution. For a deeper dive into how we eliminate hazards, visit our page on Trip Hazard Removal.

To illustrate the differences, here’s a straightforward comparison:

| Feature | Florida Sidewalk Solutions Precision Cutting (for trip hazards) | Full Replacement (for trip hazards) |

|---|---|---|

| Cost | Extremely Low (approx. 1/10 of replacement) | Very High |

| Time | Very Fast (minutes per hazard) | Very Slow (days to weeks) |

| Disruption | Minimal (quick return-to-service) | Significant (ramp closure) |

| Durability | Long-lasting (eliminates existing hazard) | Long-lasting (new construction) |

| ADA Compliance | Excellent (creates smooth, beveled transition) | Excellent (if done correctly) |

| Mess/Waste | Minimal | Significant |

How Repairs Can Ensure ADA and Building Code Compliance

Concrete Wheelchair Ramp Repair isn’t just about fixing surfaces; it’s about meeting strict accessibility standards. A proper repair requires understanding and adhering to these critical requirements to protect users and ensure compliance.

The Americans with Disabilities Act (ADA) is law. When addressing trip hazards, every cut must maintain or restore full ADA compliance. Minor details can determine whether a ramp is truly accessible or creates new barriers.

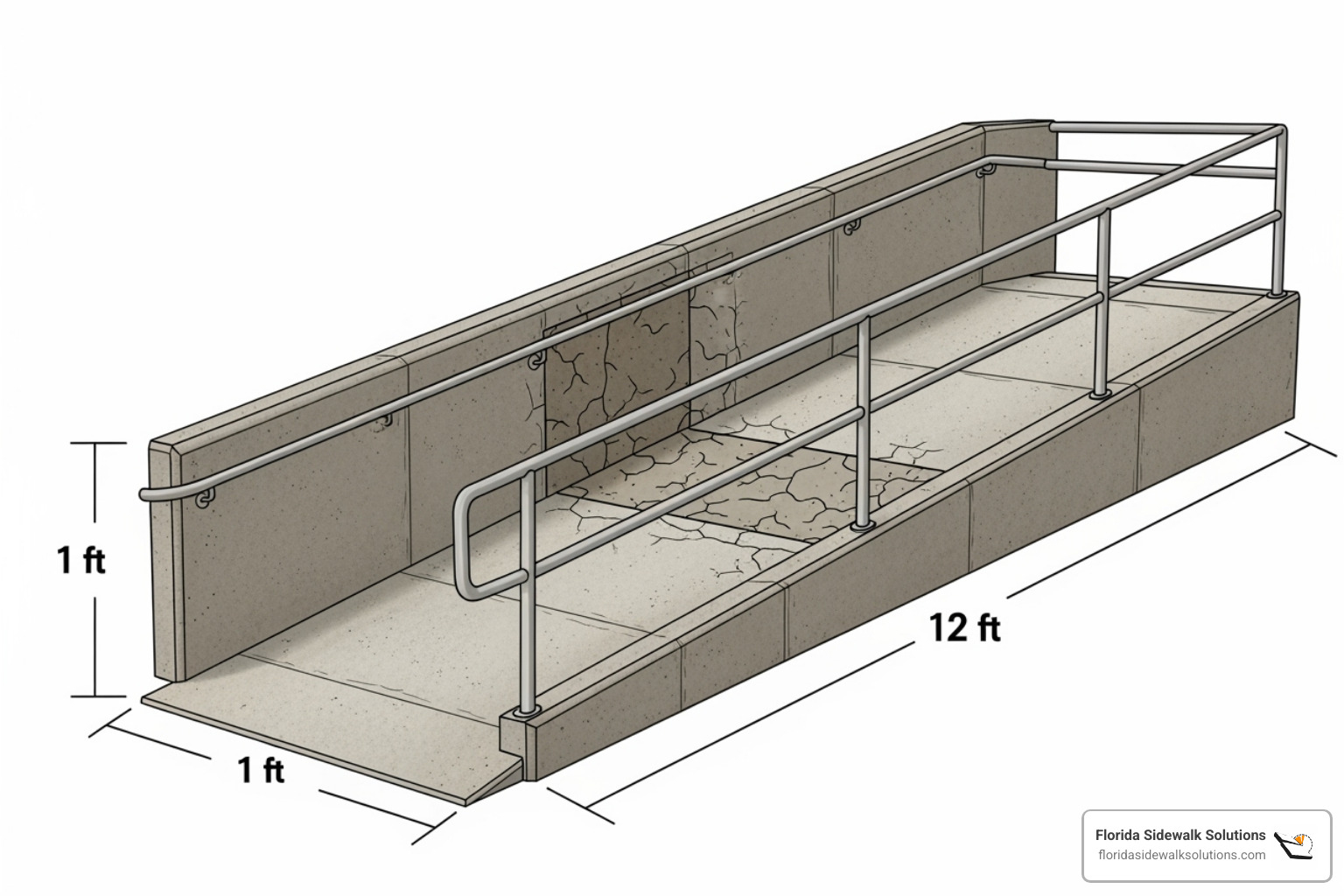

Key ADA standards include slope requirements. The maximum slope is 1:12 (one inch of rise per 12 inches of run), and the maximum cross-slope is 1:48 to prevent water pooling. Our precision cutting method eliminates trip hazards while carefully maintaining these critical ratios, ensuring a repair doesn’t create a new violation.

The beauty of our specialized approach is that it naturally supports ADA compliance. By creating smooth, beveled transitions, we eliminate trip hazards while maintaining the ramp’s original design specifications. This precision helps property managers achieve excellent NSPIRE scores by enhancing overall accessibility.

For properties subject to HUD inspections, this attention to ADA compliance is essential for ensuring residents have safe, dignified access. To understand the broader context of these requirements, explore our guide on ADA Regulations and Their Importance.

Key ADA Metrics for Your Concrete Wheelchair Ramp Repair

Adhering to specific ADA metrics is crucial for effective Concrete Wheelchair Ramp Repair. These standards ensure safe access for everyone.

- Maximum Slope (1:12): We ensure our repairs maintain this crucial ratio, as compromising it creates a more significant accessibility problem.

- Trip Hazard Height (1/4 inch): The ADA defines any vertical change of 1/4 inch or more as a trip hazard. Our patented technology eliminates these hazards by creating smooth, beveled transitions that meet ADA specifications.

- Clear Width (36 inches): Our surface repairs are performed without compromising the mandatory 36-inch minimum clear path between handrails.

- Level Landings (60 inches long): We ensure our repairs do not encroach on the required 60-inch long level landings at the top and bottom of ramps.

Our detailed understanding of these metrics ensures every repair project improves accessibility. For comprehensive guidance, check out our resource How to Have an ADA Compliant Sidewalk.

Avoiding Common Compliance Pitfalls in Repairs

Poorly executed Concrete Wheelchair Ramp Repair can create new accessibility barriers. Inexperienced work often makes ramps less compliant. Common pitfalls include:

- Incorrect Slope After Repair: Patching or improper grinding can violate the 1:12 slope rule. Our precision cutting removes material in controlled amounts, preserving the correct gradient.

- Creating New Barriers: Some repairs leave behind rough textures or create new uneven joints. Our cutting technique eliminates hazards without introducing new ones.

- Insufficient Landing Space: Repairs can mistakenly encroach on the 60-inch landing zones required for safe maneuvering. We always preserve these essential spaces.

- Non-compliant Handrails: Surface repairs can affect handrail height or stability. We are mindful of these systems to ensure they remain compliant.

Understanding these potential pitfalls helps explain why specialized expertise matters. It’s not enough to just smooth out rough spots—every repair must improve overall accessibility. For more insights, visit our page on Sidewalk or Walkway Repairs for Compliance.

Deciding Between Repair and Full Replacement

A key question in Concrete Wheelchair Ramp Repair is whether to repair or replace. This decision balances cost against the need for a long-term solution. As trip hazard specialists, we evaluate your ramp to determine the most effective approach based on a few key factors.

- Structural Integrity: The primary factor is whether the concrete and its foundation are sound. Surface repairs cannot fix a failing sub-base.

- Extent of Damage: We assess whether the damage is localized (ideal for repair) or widespread, which may make replacement more cost-effective.

- Cost-Benefit Analysis: We consider long-term value. While our method is 1/10 the cost of replacement, we ensure it’s a durable solution, not a temporary fix.

For most trip hazard situations, our specialized approach offers the perfect middle ground—you get ADA compliance and safety without the massive disruption and expense of starting over. Learn more about our general approach to Concrete Leveling and Repair.

When to Choose Concrete Wheelchair Ramp Repair

Repair is the best option when the ramp’s underlying structure is sound, and the issues are primarily surface-level. Choose repair for:

- Localized Damage: Ideal for targeting a few problem spots without affecting the rest of the ramp.

- Uneven Slabs or Joints: Our precision cutting technology is designed specifically to level these trip hazards and create smooth, ADA-compliant transitions.

- Surface Spalling: Flaking or pitting that is not structurally compromising can be effectively repaired.

- Minor to Moderate Cracks: Surface-level cracks that do not threaten the ramp’s stability.

- Budget Constraints: Repair allows you to address multiple hazards for the cost of a single replacement section.

- Minimal Disruption: Our work is fast and clean, avoiding long-term closures and rerouting.

- Trip Hazard Removal: For ADA compliance, repair is the most efficient and economical choice to eliminate hazards.

When a Full Ramp Replacement is Unavoidable

While our precision cutting is versatile, some conditions require full replacement. We are always transparent when a ramp has deteriorated beyond repair.

- Extensive Structural Cracking: Deep, widespread fissures that indicate fundamental failure of the concrete.

- Crumbling Concrete: Disintegrating concrete with exposed, loose aggregate that cannot be effectively repaired.

- Foundational Shifting or Sinking: When the ground or sub-base is unstable, surface repairs are ineffective.

- Inability to Meet ADA Slope: If a ramp’s original construction is too steep, only replacement can correct the fundamental design flaw.

- End of Service Life: When a ramp is old and requires constant repairs, replacement is the more economical long-term solution.

When we recommend replacement, it’s because we genuinely believe it’s your best option for safety, compliance, and long-term value.

Conclusion: Choosing the Right Path for a Safe and Accessible Ramp

Choosing the right Concrete Wheelchair Ramp Repair solution doesn’t have to be complicated. As we’ve covered, identifying and fixing even small flaws is critical for safety and accessibility. Most ramp issues, like uneven slabs and surface trip hazards, don’t require full replacement. Targeted repair is a cost-effective and time-saving alternative.

Safety is the top priority. With falls causing 32% of all nonfatal injuries, even a quarter-inch trip hazard poses a significant risk. Proper repair ensures safe pathways for everyone.

ADA compliance is a legal and moral requirement. Correct repairs provide essential access for people with mobility challenges, parents with strollers, and the entire community. A well-executed repair can extend your ramp’s life for years while maintaining full compliance with ADA standards.

For trip hazards, the most common ramp problem, Florida Sidewalk Solutions’ precision cutting method is the most effective and economical solution. Our patented technology eliminates uneven surfaces with surgical precision, creating smooth, confident transitions for wheelchair users.

Our approach is cost-effective (1/10th the cost of replacement), minimally disruptive, and durably effective. It ensures your ramp meets ADA requirements without the cost and hassle of major construction.

Proactively addressing ramp safety protects your users and your budget. Don’t wait for an injury or a costly compliance issue. Our precision cutting technology can transform trip hazards into smooth, compliant surfaces. Remove Trip Hazards for ADA Compliance and create the safe, inclusive environment your community deserves.