Why Uneven Sidewalks Are More Than Just an Eyesore

Trip hazard removal is the process of eliminating dangerous vertical changes in sidewalk surfaces that can cause pedestrians to trip and fall. Here’s what you need to know:

Common Trip Hazard Removal Methods:

- Saw-cutting – Precise horizontal cuts that create ADA-compliant slopes

- Grinding/Scarifying – Surface abrasion that levels raised areas

- Full replacement – Complete removal and replacement of concrete panels

Key Benefits:

- Eliminates liability from trip-and-fall accidents

- Ensures ADA compliance (removes vertical changes over 1/4 inch)

- Costs 70-90% less than full sidewalk replacement

- Provides immediate pedestrian access after repair

As a municipal maintenance manager, you know that cracked and uneven sidewalks create serious problems beyond aesthetics. The Americans with Disabilities Act (ADA) defines a trip hazard as any vertical change of 1/4 inch or more at a joint or crack – and failure to address these hazards can result in costly lawsuits and ADA violation fines.

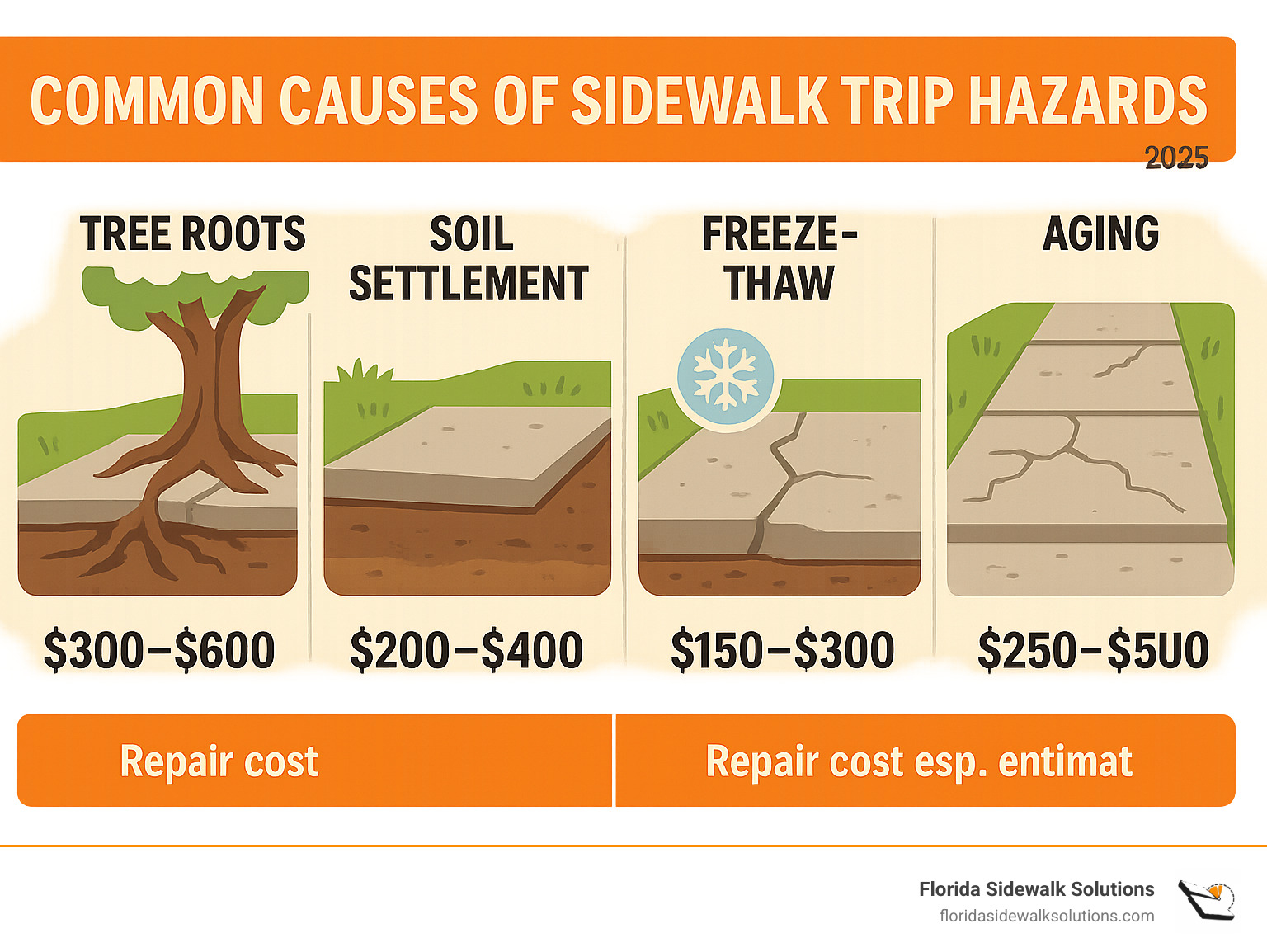

Trip hazards typically develop when tree roots push up concrete slabs, ground settling causes panels to shift, or freeze-thaw cycles create uneven surfaces. These seemingly minor imperfections pose significant safety risks, especially for elderly pedestrians, individuals with disabilities, and anyone using mobility devices.

“Trip hazards represent a legal liability to our clients,” notes industry research. “The ADA demands strict compliance.” For municipalities operating under tight budgets, the challenge becomes finding cost-effective solutions that eliminate hazards without breaking the bank or disrupting pedestrian traffic for extended periods.

Important trip hazard removal terms:

Understanding the Risks: Legal and Financial Liabilities of Trip Hazards

That innocent-looking crack in your sidewalk might seem harmless, but it could be costing you more than you think. When sidewalks become uneven, they create serious legal and financial risks that can catch property owners and municipalities off guard.

The ADA is crystal clear about what makes a sidewalk dangerous. According to the official ADA Accessibility Standards, any vertical change of ¼ inch or more at a joint or crack officially becomes a trip hazard under federal law. This isn’t just a suggestion – it’s a strict standard designed to keep everyone safe, especially people with disabilities who depend on smooth walkways to get around.

Think about it: a quarter-inch doesn’t sound like much, but when someone is walking and not expecting that little bump, it can send them tumbling. For someone using a wheelchair or walker, even that small change can be a major obstacle.

Why do these hazards happen in the first place? Nature doesn’t make it easy for us. Tree roots are constantly growing and pushing up concrete slabs as they search for water. The ground naturally settles over time, causing some panels to sink while others stay put. Even Florida’s warm weather causes concrete to expand and contract, creating cracks and uneven spots.

Here’s where things get expensive fast. When someone trips and falls because of an unaddressed hazard, the lawsuits can be devastating. Property owners face claims for medical bills, lost wages, pain and suffering, and legal fees that can easily reach into the hundreds of thousands of dollars.

For businesses, there’s also the reputation damage to consider. Word travels fast when someone gets hurt on your property, and insurance premiums often skyrocket after a claim.

Municipalities face even bigger headaches. Cities and counties are responsible for public sidewalks, and failing to maintain them can trigger class-action lawsuits and hefty ADA violation fines. The cost of defending multiple lawsuits while still having to fix the original problems can quickly drain public budgets.

The smart approach? Proactive trip hazard removal before accidents happen. It’s always cheaper to prevent a lawsuit than to fight one in court. Plus, you’ll sleep better knowing your sidewalks are safe for everyone who uses them – from kids riding bikes to grandparents taking evening walks.

Every uneven sidewalk is essentially an accident waiting to happen. The question isn’t whether you can afford to fix it, but whether you can afford not to.

Why Outdated Methods Fall Short for Sidewalk Trip Hazard Repair

For decades, property owners and municipalities have tackled uneven sidewalks using the same old playbook. You know the drill – grind it down, tear it out, or just slap a patch on it and hope for the best. But here’s the thing: these traditional approaches often create more headaches than they solve, leaving you with rough surfaces, blown budgets, and trip hazards that stubbornly refuse to stay fixed.

Let’s talk about surface abrasion – the grinding and scarifying method that’s been around forever. Picture this: a crew shows up with loud, dusty equipment and basically takes a cheese grater to your sidewalk. They’re lowering that raised section, but what you end up with is far from ideal.

The rough surface texture left behind by grinding looks terrible and can actually create new safety issues. When it rains, that pitted, uneven surface becomes slippery – you’ve traded one hazard for another! Even worse, most grinding equipment simply can’t reach the edges where the sidewalk meets buildings or landscaping. This means the trip hazard often remains right where people need safe passage most.

Then there’s the dust creation – clouds of concrete particles that coat everything in sight and pose real respiratory concerns. Your maintenance crews need protective equipment, nearby businesses get frustrated, and someone still has to deal with the massive cleanup afterward. It’s messy, disruptive, and frankly, pretty outdated for today’s standards.

Complete removal and replacement might seem like the “gold standard” solution, but it’s often overkill that breaks the budget. When you tear out entire concrete panels and start from scratch, you’re looking at costs that are 70-90% higher than modern repair methods. Our research shows that replacement can be up to 10 times more expensive than precision cutting techniques.

The time factor alone makes full replacement impractical for most situations. You’re talking about days or even weeks of disruption – tearing out old concrete, preparing the base, pouring new material, and waiting for it to cure. During all that time, pedestrians are detoured, businesses lose foot traffic, and your community deals with ongoing construction noise and dust.

Here’s something that really gets overlooked: the environmental impact is enormous. Removing and replacing just 100 concrete panels creates approximately 59 tonnes of concrete waste heading straight to landfills. In an era where sustainability matters more than ever, this kind of waste simply doesn’t make sense for routine trip hazard removal.

Perhaps most frustrating of all, these traditional methods often ignore the root cause of the problem. If tree roots or soil settlement created the original hazard, your shiny new concrete panel will likely develop the same issues down the road. You’ve spent a fortune on a temporary fix that’s destined to fail again.

The reality is that these outdated approaches were developed in an era when we had fewer options and lower expectations. Today’s communities deserve trip hazard removal solutions that are cost-effective, environmentally responsible, and provide long-lasting results without the disruption and expense of yesterday’s methods.

The Florida Sidewalk Solutions Method: Precision Horizontal Saw-Cutting for Trip Hazard Removal

At Florida Sidewalk Solutions, we’ve completely reimagined how trip hazard removal should work. Instead of the messy, expensive, and disruptive methods of the past, we’ve developed a patented saw-cutting technique that delivers results you can actually be proud of – while saving you serious money in the process.

Think of our proprietary technology as precision surgery for your sidewalks. While traditional methods essentially attack the concrete with brute force, our approach is surgical. We make precise horizontal cuts that create smooth, tapered transitions directly into your existing sidewalk. No rough patches, no ugly scars, no dangerous lips left behind.

Our edge-to-edge repair capability is what really sets us apart. Those tricky spots where grinders give up – right next to walls, gutters, or property lines – are exactly where we shine. We cut completely from edge to edge, ensuring every single hazard is eliminated and your sidewalk meets strict ADA compliance standards.

The results speak for themselves. You’ll save 70-90% compared to full replacement costs, and municipalities often find our service costs just 15-20% of what they’d spend tearing out and replacing concrete panels. When you’re managing tight budgets and long lists of needed repairs, those savings add up fast.

Speed is another game-changer. Our small two-person crews can tackle approximately 100 hazards in a single day. That means your sidewalk problems get solved quickly, with minimal disruption to foot traffic, businesses, and daily life in your community.

The Precision Process of Saw-Cutting for Trip Hazard Removal

When you work with us for trip hazard removal, you’re getting a carefully orchestrated process designed for precision and peace of mind. We start with thorough inspection and marking, where our expert technicians identify every hazard using the ADA’s strict 1/4 inch rule as our guide.

The magic happens during our beveled slope creation. Using our patented saw-cutting technology, we create smooth, graduated slopes that gently transition from the raised section to the lower section. Instead of that abrupt “lip” that catches toes and wheelchair wheels, you get a seamless surface that flows naturally.

Our goal is achieving what we call zero-point differential – bringing those previously uneven sections to a perfectly level plane. It’s like the hazard never existed in the first place.

GPS reporting and management software might sound fancy, but it’s incredibly practical. We document every single cut with GPS precision, feeding all that data into specialized management software. You get detailed reports showing exactly what was done, where, and when. This documentation is invaluable for asset management and provides solid protection if liability questions ever arise.

The best part? Minimal disruption throughout the entire process. Our compact, mobile equipment means we can work efficiently without major closures. In most cases, pedestrians can use the repaired sidewalk immediately after we’re done. No waiting days or weeks for concrete to cure.

Key Advantages for Property Owners and Municipalities

The change from old-school methods to our precision saw-cutting delivers advantages that make a real difference in your daily operations and long-term planning.

| Feature | Florida Sidewalk Solutions’ Saw-Cutting Method | Outdated Methods (Grinding/Replacement) |

|---|---|---|

| Cost | 70-90% cheaper than replacement | Up to 10x more expensive |

| Time Efficiency | Rapid (100 hazards/day, 2-person crew) | Time-consuming (days/weeks for replacement) |

| ADA Compliance | Guaranteed ADA-compliant slopes | Often leaves non-compliant areas |

| Environmental Impact | Minimal waste (0.3 tonnes/100 hazards) | High waste (59 tonnes/100 panels) |

| Disruption | Very low, immediate pedestrian access | High, prolonged closures |

| Surface Finish | Smooth, clean, aesthetic | Rough, abraded, unsightly |

Cost savings remain the most compelling reason to make the switch. When repairs cost more than 10 times less than removal and replacement, you can address significantly more hazards within the same budget. That means safer sidewalks throughout your entire community, not just the worst trouble spots.

Time efficiency translates to real convenience for everyone involved. Faster completion means less disruption for businesses, fewer detours for pedestrians, and reduced labor costs for you. Projects that used to drag on for weeks can now be completed in days.

Guaranteed compliance eliminates the guesswork and worry about ADA requirements. Our precision cutting ensures every repair meets strict federal guidelines, protecting you from costly fines and legal liabilities. As our research shows, our patented technology “completely and cleanly removes trip hazards from sidewalks, virtually eliminating claims that result from trip and fall incidents.”

Reduced liability gives you the peace of mind that comes from proactive risk management. By addressing hazards before accidents happen, you’re protecting both pedestrians and your organization from the financial and reputational damage of trip-and-fall incidents.

Improved aesthetics mean your sidewalks actually look better after repair, not worse. Unlike the patchy, rough results from grinding or the obvious newness of replacement panels, our repairs blend seamlessly with existing concrete. Your community looks well-maintained and professional.

Environmental responsibility is built into every job we complete. Using our method for 100 trip hazards results in just 0.3 tonnes of concrete waste compared to 59 tonnes from replacement methods. We also save approximately 530 litres of fuel and reduce CO2 emissions by 1.3 metric tonnes. It’s a win for your budget and the planet.

Proactive Sidewalk Management and The Repair Process

Smart trip hazard removal starts long before someone gets hurt. The best approach? Catch problems early and fix them before they become expensive lawsuits or serious accidents. Think of it like maintaining your car – regular check-ups cost a lot less than waiting for the engine to blow up.

The reality is that sidewalks don’t fix themselves. Tree roots keep growing, soil keeps settling, and those little quarter-inch bumps keep getting bigger. But with the right management approach, you can stay ahead of these problems instead of constantly playing catch-up.

How to Identify and Manage Hazards Proactively

Building an effective sidewalk management system doesn’t require a PhD in engineering – just some common sense and consistent effort. The key is making hazard identification a routine part of your property maintenance, not something you think about only after someone trips.

Regular inspections form the backbone of any good management plan. Walk your sidewalks at least twice a year, looking specifically for vertical changes of 1/4 inch or more. Pay special attention to areas where tree roots are active, where heavy foot traffic creates wear patterns, or where water tends to pool and cause erosion. Your maintenance staff can easily learn to spot these issues with basic training.

Creating a maintenance plan means turning those inspection findings into action. Not every hazard needs immediate attention, but every hazard needs to be on your radar. High-traffic areas like building entrances, school zones, and accessible routes should always get priority. Areas with less foot traffic can often wait for the next maintenance cycle.

Documenting hazards used to mean clipboards and filing cabinets. Today’s technology makes this much easier. Modern trip hazard removal services like ours provide detailed GPS reporting that creates a digital map of every problem spot. This documentation serves double duty – it helps you track repairs and proves you’re taking reasonable care of your property if legal questions ever arise.

Prioritizing repairs becomes straightforward once you have good documentation. Focus first on the most dangerous spots and the areas with the highest liability exposure. A quarter-inch bump in front of a busy restaurant entrance needs attention before a similar problem on a rarely-used side path.

What to Expect When Hiring a Professional Trip Hazard Removal Service

Choosing professional trip hazard removal should feel like hiring any other skilled trade – straightforward, transparent, and focused on solving your problem efficiently. Here’s exactly what happens when you work with Florida Sidewalk Solutions.

Initial consultation starts with a real conversation about your specific situation. We’ll discuss the scope of your sidewalk network, any problem areas you’ve noticed, and what’s keeping you up at night about liability. This isn’t a high-pressure sales pitch – it’s about understanding your needs and explaining how our process works.

Free estimate means exactly that – no hidden fees, no surprises, no obligation. Our pricing reflects the significant cost savings our saw-cutting method offers compared to traditional repairs. We believe in upfront honesty because long-term relationships matter more than quick sales.

On-site work process is designed to minimize disruption to your daily operations. Our two-person crew arrives with specialized, compact equipment that’s surprisingly quiet and clean. The work happens quickly – we can complete large projects in a fraction of the time traditional methods require. Pedestrians can usually walk on the repaired areas immediately after we finish. We guarantee no damage to adjacent concrete, landscaping, utility covers, or surrounding structures.

Crew and equipment represent years of specialized training and proprietary technology. Our technicians are experts in operating our patented saw-cutting equipment, which is designed to be mobile and precise. Whether you’re dealing with busy city sidewalks or quiet residential pathways, we can work effectively in any environment.

Post-job reporting provides the documentation you need for your records and peace of mind. Every completed project comes with a detailed “works complete report” that includes GPS coordinates of every hazard removed, plus before-and-after photos. This verifiable proof of compliance is invaluable for liability management and future audits. We can provide these reports daily or weekly, whatever works best for your needs.

The bottom line? Professional trip hazard removal should solve your problem completely, cost-effectively, and with minimal hassle. That’s exactly what our process delivers.

Frequently Asked Questions about Sidewalk Trip Hazard Repair

Let’s address the most common questions we hear about trip hazard removal and ADA compliance. These are real concerns from property managers, municipal officials, and business owners just like you.

What officially makes a sidewalk crack an ADA trip hazard?

This is probably our most frequently asked question, and it’s an important one. The Americans with Disabilities Act defines a trip hazard as any vertical change in level of 1/4 inch or more at a joint or crack. That’s it – just a quarter of an inch. It might seem small, but this precise measurement makes a huge difference for someone using a wheelchair, walker, or cane.

Think about it this way: what feels like a minor bump to most people can be a major obstacle for someone with mobility challenges. The ADA didn’t pick this measurement arbitrarily – it’s based on real safety data and accessibility needs. Even that slight deviation can cause serious falls, especially for elderly pedestrians or anyone not expecting the change in elevation.

Is surface abrasion the same as saw-cutting?

Not at all – and understanding the difference could save you thousands of dollars and a lot of headaches. Surface abrasion methods like grinding often leave a rough texture and may not reach the edges, while our saw-cutting method makes a precise, clean cut from edge to edge.

Here’s what typically happens with grinding: the machine grinds down the raised concrete, but it often can’t get right to the edges where sidewalks meet walls or gutters. This means the trip hazard often remains at the most critical spots. Plus, grinding leaves behind a rough, pitted surface that not only looks unprofessional but can actually create new slip hazards when wet.

Our patented saw-cutting approach is completely different. We make a precise horizontal cut that creates a smooth, uniform slope from edge to edge. The result is a clean transition that meets ADA compliance requirements and looks great too. No rough patches, no remaining lips at the edges, and no compromise on safety or aesthetics.

Is it cheaper to repair a trip hazard or replace the whole sidewalk panel?

This is where our clients really see the value of modern trip hazard removal technology. Repairing with Florida Sidewalk Solutions’ saw-cutting method is often 70-90% cheaper than full panel replacement. We’re talking about massive savings here.

Consider this: removing and replacing a single concrete panel involves demolition, hauling away debris, preparing the base, pouring new concrete, and waiting for it to cure. That’s days of work, heavy equipment, and significant material costs. Our repair method takes just minutes per hazard and allows immediate pedestrian access.

The numbers speak for themselves – our method is more than 10 times less expensive than traditional removal and replacement. This means you can address ten times more hazards with the same budget, making your entire property safer instead of just fixing one or two panels. For municipalities managing miles of sidewalks, this cost difference is absolutely game-changing.

Plus, you’re not creating tons of concrete waste or dealing with the environmental impact of full replacement. It’s better for your budget and better for the planet.

Conclusion: Invest in Safety, Compliance, and Peace of Mind

When you walk past an uneven sidewalk, you’re looking at more than just a cosmetic problem. Those seemingly small cracks and raised sections represent real dangers that can lead to serious injuries, expensive lawsuits, and costly ADA violations. Every day these hazards remain unaddressed, they put pedestrians at risk and expose you to growing liability.

The good news? You don’t have to live with these risks or break your budget trying to fix them.

Modern trip hazard removal methods have completely changed the game. Our precision saw-cutting technology at Florida Sidewalk Solutions proves that you can achieve superior results while spending a fraction of what traditional methods cost. We’re not just patching problems – we’re providing lasting solutions that protect both your community and your bottom line.

When you choose our approach, you’re making a smart investment that delivers long-term value in multiple ways. You’re dramatically reducing liability by eliminating the trip hazards that cause accidents and lawsuits. You’re preserving your existing concrete assets instead of wastefully tearing them out. Most importantly, you’re ensuring that every person who walks on your sidewalks – whether they use a wheelchair, walker, or simply want to stroll safely – can do so without fear.

The environmental benefits matter too. While traditional replacement methods send tons of concrete to landfills, our precision cutting approach produces minimal waste. It’s the responsible choice for communities that care about their environmental footprint.

From busy municipal sidewalks to private commercial properties, we’ve seen how proper trip hazard removal transforms spaces. Pedestrians feel safer, property owners sleep better knowing they’re compliant with ADA standards, and communities can allocate their maintenance budgets more effectively.

Don’t let trip hazards become a stumbling block for your organization’s success. The solution is proven, affordable, and available right here in Florida.

Learn more about our concrete sidewalk surface repair services and find how Florida Sidewalk Solutions can help you create safer, compliant sidewalks that serve your community for years to come.