Why Modern Concrete Repair Technology is Essential for Safe Sidewalks

Concrete repair technology has revolutionized how municipalities address sidewalk safety and ADA compliance. Instead of costly full replacements, advanced methods now offer precise, permanent solutions that save both time and taxpayer dollars.

Key concrete repair technologies for sidewalks:

- Precision Concrete Cutting – Removes trip hazards with clean, accurate cuts

- Polyurethane Foam Injection – Lifts sunken slabs by filling voids underneath

- Concrete Grinding – Smooths uneven surfaces (but creates dust and rough finishes)

- Patching Compounds – Fills cracks and small holes (temporary solution)

- Full Replacement – Complete slab removal and reinstallation (most expensive)

The concrete repair market is booming – valued at $15.1 billion in 2022 and projected to reach USD 25.7 billion by 2030, growing at a CAGR of 6.9% from 2023 to 2030. This growth reflects municipalities’ urgent need for cost-effective solutions to aging infrastructure.

According to the Americans with Disabilities Act, any vertical change over 1/4 inch creates a trip hazard that must be corrected. Traditional methods like grinding often fall short of creating truly compliant surfaces, while precision cutting technology delivers clean, level results that meet ADA standards.

As one city administrator noted: “The cost effectiveness and superior results of this method over other trip hazard removal techniques led us to expand our contract to include all city sidewalks.”

Modern repair technology isn’t just about fixing concrete – it’s about reducing liability, ensuring public safety, and maximizing budget efficiency. The right approach can transform dangerous walkways into compliant, durable surfaces that serve communities for decades.

Understanding Sidewalk Damage and Why It Matters

Walking down any neighborhood street, you’ve probably noticed those telltale signs of aging sidewalks – the raised edges, uneven joints, and cracked surfaces that make you watch your step a little more carefully. These aren’t just cosmetic issues that affect curb appeal; they represent genuine safety hazards that can lead to serious injuries and costly legal problems.

Concrete repair technology has evolved significantly to address these challenges, moving beyond simple patch jobs to sophisticated solutions that tackle the root causes of sidewalk damage. The most critical issue we see is vertical displacement between concrete slabs – when one section sits higher than its neighbor, creating that dangerous lip that catches toes and wheelchair wheels alike.

When sidewalk repairs are done right, they don’t just eliminate immediate trip hazards. They preserve the structural integrity of the entire walkway system, preventing small problems from becoming major headaches that require complete replacement. Think of it like fixing a small leak in your roof – address it now, or deal with much bigger problems later.

The legal stakes couldn’t be higher. Property owners and municipalities face serious legal liability when someone gets hurt on an uneven sidewalk. Under the Americans with Disabilities Act (ADA), any vertical change over 1/4 inch automatically creates a trip hazard that must be corrected. This isn’t just a suggestion – it’s the law.

That’s why professional assessment is so crucial. What looks like a simple uneven joint might actually signal deeper issues with soil settlement or root damage. Getting the diagnosis right the first time means choosing the most effective repair method based on established concrete repair techniques and avoiding costly do-overs.

Common Causes of Uneven Sidewalks

Understanding why sidewalks become uneven helps explain why some repair methods work better than others. Tree root growth tops the list of culprits – those beautiful oak trees that shade our streets have powerful root systems that can lift concrete slabs like they’re made of cardboard. It’s nature versus infrastructure, and nature usually wins round one.

Soil settlement creates another set of challenges. When the ground beneath a sidewalk shifts or compacts unevenly, the concrete above follows suit. This might happen because the soil wasn’t properly compacted during original construction, or because water has gradually washed away supporting material over the years.

In areas with changing seasons, freeze-thaw cycles wage a slow but relentless war against concrete. Water seeps into small cracks, freezes and expands, then melts and leaves behind slightly larger voids. Repeat this process hundreds of times, and you get the heaved and cracked sidewalks that plague northern climates.

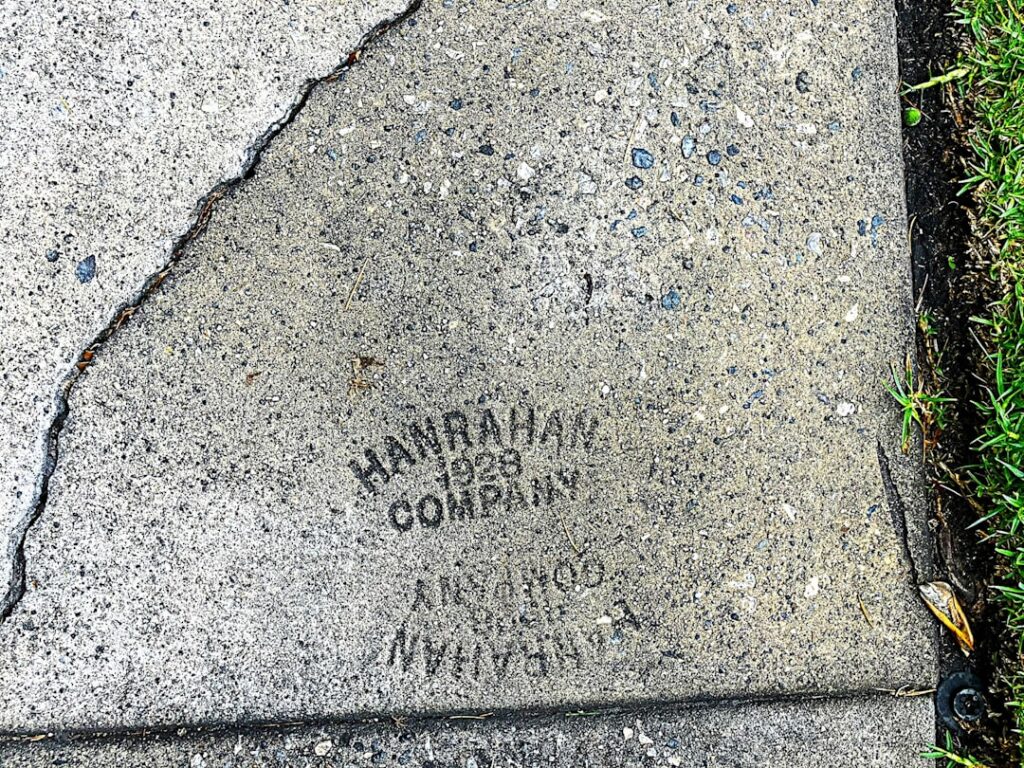

Sometimes the problem goes back to day one. Poor initial installation – whether it’s inadequate base preparation, insufficient drainage, or shortcuts in the construction process – creates weaknesses that show up years later as uneven, unstable surfaces.

Water erosion might work slowly, but it’s incredibly persistent. A downspout that dumps water in the wrong place, a leaky pipe, or even repeated heavy rains can gradually wash away the soil supporting a concrete slab, leaving it to settle into the void.

The Risks of Neglecting Repairs

Ignoring uneven sidewalks is like playing Russian roulette with public safety and your bank account. Trip-and-fall accidents are the most immediate concern – and they happen more often than you might think. What seems like a minor lip in the concrete can send someone tumbling, especially elderly pedestrians or people with mobility challenges.

The financial consequences of these accidents can be staggering. Increased liability means property owners and municipalities face expensive lawsuits, medical bills, and settlement costs that can easily reach six figures. Suddenly, that repair that seemed too expensive looks like a bargain.

From a property value standpoint, cracked and uneven sidewalks send a clear message to potential buyers: this property hasn’t been well maintained. Decreased property value affects not just individual homeowners but entire neighborhoods where poor sidewalk conditions become the norm.

Perhaps most importantly, failing to address trip hazards means failing to provide equal access to all community members. Non-compliance with ADA regulations isn’t just about avoiding fines – though those can be substantial. It’s about ensuring that everyone, regardless of their physical abilities, can safely steer our shared public spaces.

The good news? Modern concrete repair technology offers effective solutions that address these problems permanently, cost-effectively, and in compliance with all safety standards. The key is choosing the right approach for your specific situation.

An Overview of Concrete Repair Technology for Walkways

When it comes to fixing uneven sidewalks, we’ve come a long way from the “one-size-fits-all” approach of the past. The evolution of concrete repair technology has transformed how we tackle trip hazards, moving from temporary band-aid solutions to sophisticated, permanent fixes that actually work.

Think about it this way: twenty years ago, if you had a trip hazard on your sidewalk, your options were pretty limited (and not very appealing). You could grind it down, creating a dusty mess and rough surface, or you could tear everything out and start over—ouch, that’s expensive! Today’s technology has revolutionized the game entirely.

Modern concrete repair technology isn’t just about fixing what’s broken; it’s about doing it right the first time. Efficiency and effectiveness go hand in hand now, thanks to precision engineering and specialized equipment that can tackle specific problems with surgical accuracy. The role of technology has shifted from “making do” to “making perfect,” especially when it comes to meeting ADA compliance standards.

Traditional Methods: Grinding and Patching

Let’s be honest about the old-school approaches—they had their place, but they also had some pretty significant drawbacks that left both contractors and property owners scratching their heads.

Concrete grinding was the go-to method for years, and it’s exactly what it sounds like. Picture a machine essentially shaving down the higher side of an uneven joint, trying to make everything level. The problem? You end up with a rough, sandpaper-like surface that becomes slippery when wet. Plus, the dust and noise pollution made it about as popular with neighbors as a leaf blower at 6 AM on a Saturday.

Here’s the real kicker: grinding rarely achieves the smooth, precise surface needed for true ADA compliance. You might reduce the trip hazard, but you often end up with a ramped profile that can still catch someone’s toe.

Scabbling took a similar approach but with multiple steel bits chipping away at the surface. Imagine a tiny jackhammer working overtime—lots of noise, lots of mess, and still not the precision needed for a truly safe walking surface.

Patching compounds and mortars served their purpose for filling cracks and small holes, but they were never really designed for leveling significant height differences. Think of them as makeup for concrete—they can cover up minor imperfections, but they can’t fix structural issues. These patches often failed over time, especially in high-traffic areas, leading to the frustrating cycle of repair, fail, repeat.

Slab Lifting and Void Filling

When entire sections of sidewalk sink into the ground, that’s when polyurethane foam injection (also called slabjacking) and mudjacking come into play. These methods are pretty clever—they address the root cause by filling voids underneath sunken slabs.

Polyurethane foam injection works by drilling small holes into the concrete and injecting expanding foam beneath it. The foam fills the void and gently lifts the slab back to its original position. It’s quick, relatively clean, and the foam cures fast.

Mudjacking uses a similar principle but with a cement-based slurry instead of foam. It’s been around longer but requires larger holes and can add significant weight to already problematic soil.

While these methods excel at lifting entire sunken sections, they’re not really designed for the precision work needed to eliminate small trip hazards. For that typical 1/4-inch height difference that creates liability issues, these lifting methods might be overkill—or simply not precise enough to guarantee ADA compliance.

Advanced Solutions: Precision Concrete Cutting

Now we’re getting to the exciting part—where modern concrete repair technology really shines. Instead of grinding away material indiscriminately or trying to lift entire slabs, precision cutting offers a completely different approach.

This patented cutting technology works like a surgeon’s scalpel rather than a sledgehammer. It makes clean, precise cuts that remove the exact amount of concrete needed to eliminate the trip hazard—no more, no less. The result is a smooth transition that meets ADA standards without compromising the integrity of the existing concrete.

The beauty of this approach lies in its clean, uniform finish. Unlike grinding, which leaves behind a rough, dusty surface, precision cutting creates a finished edge that’s both safe and attractive. There’s minimal debris, less dust, and the walking surface feels natural underfoot.

From a financial standpoint, the cost-effectiveness compared to full replacement is remarkable. Complete sidewalk removal and replacement can cost thousands of dollars and take days to complete. Precision cutting delivers comparable safety and compliance results in a fraction of the time and at a fraction of the cost.

Perhaps most importantly, this method offers long-term durability because it creates a new, stable surface rather than relying on patches or temporary fixes. The existing concrete slab maintains its structural integrity—you’re simply removing the problematic portion with surgical precision. This means the repair lasts, and you won’t be dealing with the same issue again in a few years.

Comparing Sidewalk Repair Methods: Which is Right for You?

When your sidewalk has a dangerous trip hazard, you’re faced with several repair options. But here’s the thing – not all concrete repair technology methods are created equal. Some might seem cheaper upfront but cost you more in the long run. Others might look good temporarily but fail when you need them most.

The key is understanding what each method can actually deliver for your specific situation. We’ve worked on thousands of sidewalks, and we’ve seen how different approaches perform over time. Let’s break down your options so you can make the best decision for your property.

| Factor | Concrete Grinding | Slab Lifting (Polyurethane/Mudjacking) | Precision Concrete Cutting | Full Replacement |

|---|---|---|---|---|

| Cost | Low | Medium | Low-Medium | High |

| Durability | Short-term (can weaken) | Medium (depends on soil) | Long-term | Long-term |

| ADA Compliance | Often Fails (ramped) | Variable (good for overall lift) | Excellent | Excellent |

| Repair Time | Fast | Fast | Fast | Slow |

| Aesthetics | Poor (rough, discolored) | Good (if successful) | Excellent (clean, uniform) | Excellent (new slab) |

Grinding might seem like the obvious choice because it’s fast and cheap. But here’s what we’ve learned: it rarely creates a truly level surface. Instead, you often end up with a ramped area that still doesn’t meet ADA standards. Plus, the rough, discolored surface it leaves behind can actually be more dangerous when wet.

Slab lifting works great when you have a large sunken area – like when tree roots have pushed up an entire section. But for typical trip hazards where you just need to level a small lip or uneven joint, it’s often overkill and doesn’t give you the precision you need.

Full replacement gives you a perfect new sidewalk, but at what cost? You’re looking at days of construction, heavy equipment, disposal fees, and a price tag that can be 5-10 times higher than other methods.

Evaluating Cost vs. Long-Term Value

We get it – budget matters. But we’ve seen too many property owners choose the cheapest option only to end up paying twice (or three times) when it fails.

Think about it this way: if someone trips and gets hurt on your sidewalk, you’re not just dealing with repair costs anymore. You’re potentially facing medical bills, legal fees, and settlement costs that can reach tens of thousands of dollars. Suddenly, investing in a proper repair that actually eliminates the hazard looks like a bargain.

The hidden costs of cheap repairs add up fast. When a grinding job fails to meet ADA standards, you’ll need to fix it again. When a temporary patch cracks and creates a new trip hazard, you’re back to square one. Each time you have to redo a repair, you’re not just paying for materials and labor – you’re paying for the removal of the failed repair too.

That’s why we developed our precision cutting method. It costs more than basic grinding upfront, but it delivers a permanent solution that actually eliminates the liability risk. When you factor in the longevity and the peace of mind, it’s actually the most economical choice.

A Closer Look at Modern concrete repair technology

Here’s what makes modern concrete repair technology different: it’s designed around outcomes, not just quick fixes. Our precision cutting method focuses on three critical goals that older methods often miss.

First, true ADA compliance. The Americans with Disabilities Act doesn’t just say sidewalks should be “mostly level” – it sets a specific standard of no more than 1/4 inch vertical change. Our cutting technology can achieve this precision consistently, creating a smooth transition that meets the exact requirements.

Second, a genuinely safe walking surface. It’s not enough to just reduce a trip hazard – you need to eliminate it completely. The clean, precise cut we create doesn’t just look better than a rough ground surface; it actually provides better traction and eliminates the small lips and rough spots that can still catch someone’s toe.

Third, long-term durability. Because we’re removing the hazard with surgical precision rather than weakening the concrete through grinding, the repair maintains the structural integrity of your sidewalk. You get a solution that lasts for years, not months.

The difference between a rough, ground surface and our clean, precise cut isn’t just cosmetic – it’s functional. When it rains, ground surfaces can become slippery and treacherous. Our smooth, level cuts drain properly and provide consistent footing in all weather conditions.

This is why cities and property managers who try our method often expand their contracts to include all their sidewalks. They see the difference in quality, durability, and cost-effectiveness compared to the traditional approaches they’ve used before.

Frequently Asked Questions about Sidewalk Repair

When it comes to sidewalk safety and concrete repair technology, we hear the same concerns from property managers, city officials, and homeowners time and again. Let’s tackle the most common questions with straightforward answers that can help you make informed decisions about your sidewalk repairs.

What makes a sidewalk non-compliant with the ADA?

The Americans with Disabilities Act isn’t just legal jargon – it’s about creating safe, accessible spaces for everyone in our communities. When it comes to sidewalks, the rules are pretty clear and specific.

A change in level over 1/4 inch is typically considered a trip hazard and non-compliant with ADA standards. Picture this: if you place a quarter on the edge of one concrete slab, and the adjacent slab is higher than that quarter, you’ve got a compliance issue. It might seem like a tiny difference, but for someone using a wheelchair, walker, or even just not paying close attention while walking, that small bump can be a major obstacle or safety hazard.

But vertical changes aren’t the only concern. The slope and cross-slope of the walkway are also factors in ADA compliance. A sidewalk can’t be too steep in the direction of travel, and it can’t tilt too much to one side either. These requirements ensure that people with mobility challenges can steer safely and independently.

Our precision cutting method specifically targets these compliance issues, creating smooth transitions that meet ADA standards while eliminating trip hazards completely.

Is it cheaper to repair or replace an uneven sidewalk?

This question always makes us smile because the answer is so clear-cut. Repairing with modern technology like precision cutting is almost always significantly cheaper and faster than full removal and replacement of a concrete slab.

Think about what replacement actually involves. First, crews have to break up the old concrete with jackhammers – loud, dusty, and disruptive. Then they haul away all that heavy debris, prepare the ground underneath, set up forms, pour new concrete, and wait for it to cure. The whole area is usually blocked off for days, sometimes weeks.

Compare that to our concrete repair technology approach. We bring in our specialized equipment, make precise cuts to eliminate the trip hazard, clean up the minimal debris, and you can walk on it immediately. No waiting, no major disruption, no mountains of waste concrete heading to the landfill.

The cost difference is dramatic. We’ve seen situations where our method costs less than even basic grinding or scabbling, while delivering far superior results that actually meet ADA compliance standards.

How can I ensure a sidewalk repair is successful long-term?

Nobody wants to fix the same problem twice, and we completely understand that concern. The key to lasting sidewalk repairs lies in choosing the right approach from the start.

Choose a method that addresses the hazard permanently, like precision cutting, rather than temporary fixes that might look okay initially but fail over time. Traditional grinding, for example, can actually weaken the concrete slab by removing material, potentially creating new problems down the road.

Our cutting method creates a new, stable surface without compromising the structural integrity of the existing concrete. We’re not patching over the problem or grinding it down – we’re permanently eliminating the hazard while preserving the strength of your sidewalk.

Consider periodic inspections and sealing to prevent future water damage as part of your long-term maintenance strategy. While our repairs are built to last, a little preventive care goes a long way. Regular inspections can catch small issues before they become big problems, and quality concrete sealers help protect against moisture damage, freeze-thaw cycles, and general wear.

The bottom line? Invest in quality repair work upfront, and you’ll save money, time, and headaches for years to come. It’s really that simple.

Conclusion: Investing in the Right Technology for Safe Sidewalks

When it comes to sidewalk safety, the choice of repair method makes all the difference. We’ve seen how concrete repair technology has transformed from messy, temporary fixes to precise, permanent solutions that actually work.

The reality is simple: uneven sidewalks are dangerous. That quarter-inch lip might seem small, but it’s enough to send someone tumbling. And when that happens, everyone pays the price – the injured person, the property owner facing lawsuits, and the community dealing with unsafe walkways.

Traditional methods like grinding leave rough, uneven surfaces that often fail to meet ADA standards. Full replacement costs a fortune and disrupts entire neighborhoods for weeks. But modern concrete repair technology offers something better – a way to eliminate trip hazards completely while saving time and money.

Our precision cutting technology at Florida Sidewalk Solutions represents the best of what’s possible today. Instead of grinding away concrete and creating dust clouds, we make clean, precise cuts that eliminate the hazard entirely. The result? A smooth, level surface that meets ADA compliance standards and looks great too.

The numbers don’t lie – our method costs significantly less than full replacement while delivering superior results compared to grinding or patching. More importantly, it creates truly safe walkways that protect everyone who uses them.

Think about it this way: investing in proper sidewalk repair isn’t just about fixing concrete. It’s about reducing liability risks, enhancing community safety, and ensuring that everyone – from kids on bikes to grandparents with walkers – can steer our sidewalks with confidence.

At Florida Sidewalk Solutions, we’ve made it our mission to make sidewalks safer across Davie FL, Fort Lauderdale FL, Coral Springs FL, Boca Raton FL, West Palm Beach FL, Miami FL, and Fort Myers FL. Our patented approach proves that you don’t have to choose between quality and affordability when it comes to sidewalk safety.

The choice is clear: you can keep patching problems with outdated methods, or you can invest in technology that actually solves them. We believe every community deserves walkways that are safe, compliant, and built to last.

Ready to transform your dangerous sidewalks into safe pathways for everyone? Learn more about our professional sidewalk repair services and find how we can help you address your concrete repair needs with precision, efficiency, and lasting results.