Concrete trip hazard repair is a critical task for ensuring both public safety and compliance with regulations. This is especially important for municipal maintenance managers responsible for maintaining city sidewalks that must meet ADA standards. Uneven concrete can pose significant risks, potentially leading to accidents and ensuing liabilities for those who are responsible for sidewalk maintenance.

Addressing these hazards is not just about avoiding legal headaches. It’s about taking proactive steps to protect community members, especially vulnerable groups like seniors and children, from the dangers hidden in plain sight as they walk down the street.

- Safety: Reducing risks of trips and injuries.

- Liability: Avoiding potential lawsuits from accidents.

- Compliance: Meeting ADA and local regulatory standards.

Addressing these hazards efficiently and economically is a priority. Innovations in concrete cutting techniques—such as the methods employed by Florida Sidewalk Solutions—allow for precision repairs that are less invasive and more cost-effective than traditional methods.

Understanding Concrete Trip Hazards

Concrete trip hazards can sneak up on you. They often appear as unexpected changes in elevation on sidewalks or pathways. These slight bumps or dips might not seem like a big deal, but they can be dangerous.

Safety Concerns

Imagine walking down a familiar street and suddenly tripping over a small bump in the sidewalk. That’s the risk of a concrete trip hazard. These uneven surfaces can cause falls and injuries, especially for seniors and children.

The consequences can be severe. A simple trip can lead to broken bones, sprains, or worse. That’s why it’s crucial to address these hazards promptly.

ADA Compliance

The Americans with Disabilities Act (ADA) sets standards to ensure public spaces are accessible to everyone. This includes maintaining level sidewalks. When sidewalks are uneven, they can become barriers for people with disabilities, such as those using wheelchairs or walkers.

Ensuring ADA compliance isn’t just a legal requirement—it’s a commitment to making public spaces safe and accessible for all. Repairing trip hazards is a key part of this commitment.

Unexpected Elevation Changes

Concrete sidewalks can shift over time. Soil movement, tree roots, or even weather changes can cause slabs to heave or settle. These shifts create unexpected elevation changes, leading to those pesky trip hazards.

Florida Sidewalk Solutions specializes in addressing these problems effectively. Their cutting-edge methods offer a precise fix, making sidewalks safe again without the need for costly replacements.

Understanding and addressing concrete trip hazards is essential for public safety and compliance. By focusing on these issues, we can create safer, more accessible communities for everyone.

Methods for Concrete Trip Hazard Repair

Addressing concrete trip hazards effectively requires understanding the best methods for repair. Let’s explore three main techniques: grinding, using a scarifier, and leveling.

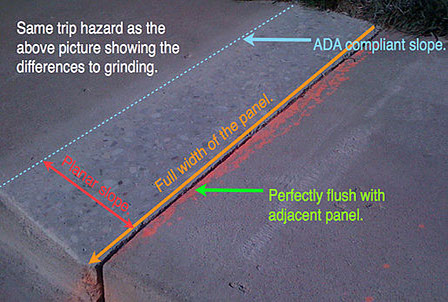

Grinding

Grinding is a common method for smoothing out minor trip hazards. It involves using a concrete grinder to gradually wear down the high spots on an uneven surface. This technique is effective for small elevation changes and creates a smooth transition between slabs.

Pros:

- Cost-effective for minor repairs

- Quick process for small areas

- Creates a non-slip surface

Cons:

- Produces a lot of dust, requiring proper dust control measures

- Not suitable for large or severely uneven areas

Using a Scarifier

For more severe trip hazards, a scarifier might be the tool of choice. A scarifier, or surface planer, uses heavy cutting wheels to chip away at the surface. This method is excellent for addressing larger height differences and can quickly remove layers of concrete.

Pros:

- Fast and effective for significant height differences

- Can handle larger areas than grinding

Cons:

- Requires professional handling due to its aggressive nature

- May leave a rougher surface that needs further smoothing

Leveling

Leveling involves adjusting the height of concrete slabs to eliminate trip hazards. This can be done using methods like mud-jacking or foam injection, where material is pumped under the slab to raise it to the desired level.

Pros:

- Provides a long-term solution

- Restores the original level of the sidewalk

Cons:

- More expensive than grinding or using a scarifier

- Requires professional expertise

Florida Sidewalk Solutions offers a unique approach to these methods, utilizing precision cutting technology to address trip hazards efficiently. This approach not only saves time and money but also ensures compliance with ADA standards, making sidewalks safe and accessible for everyone.

By choosing the right method for each situation, you can effectively eliminate trip hazards and improve the safety of your sidewalks.

DIY vs. Professional Repair

When it comes to concrete trip hazard repair, deciding between a DIY approach and hiring professionals can make a significant difference in cost, safety, and effectiveness. Let’s break down the considerations:

Cost-Effective Choices

DIY repairs can be tempting due to the lower initial costs. For minor trip hazards, using a concrete grinder yourself might seem like a budget-friendly option. However, it’s crucial to consider the hidden costs of purchasing or renting tools, safety gear, and materials. Additionally, mistakes in DIY repairs can lead to more significant issues down the line, potentially increasing overall expenses.

On the other hand, hiring professional repair services like Florida Sidewalk Solutions might have a higher upfront cost, but it often proves more cost-effective in the long run. Professionals have the expertise to ensure durable, ADA-compliant repairs, reducing the risk of future liabilities or repeated fixes.

Tools and Equipment

For those considering a DIY approach, the right tools are essential. You’ll need:

- A concrete grinder for small trip hazards

- Safety gear, including masks, gloves, and goggles

- Dust control equipment to manage silica dust

However, more severe trip hazards require advanced tools like scarifiers or leveling equipment. These are typically available only through professional services, which also have the expertise to use them effectively.

Safety Precautions

Safety is paramount in any repair work. Concrete grinding and scarifying can produce hazardous dust containing silica, which is carcinogenic. Proper dust control measures are necessary to protect your health. Always wear appropriate protective gear, such as respirators, gloves, and eye protection.

Professionals are trained in these safety measures and follow strict protocols to ensure a safe working environment. This not only protects the workers but also ensures the safety of residents and pedestrians in the area.

Making the Right Choice

While DIY repairs might seem appealing for minor issues, the complexity and potential risks involved in concrete trip hazard repair often make professional services a wiser choice. Florida Sidewalk Solutions offers proven expertise and cutting-edge technology to address trip hazards efficiently, ensuring safety and compliance with ADA standards.

Choosing a professional service ensures that your sidewalks are not only safe but also long-lasting, ultimately saving you time, money, and potential legal issues.

Concrete Trip Hazard Repair: Best Practices

When tackling concrete trip hazard repair, following best practices is essential for ensuring safety, compliance, and durability. Let’s explore some key areas: dust control, protective gear, and material selection.

Dust Control

Concrete grinding and cutting can generate a significant amount of dust, particularly silica dust, which is harmful if inhaled. Effective dust control is vital to protect both workers and nearby residents.

-

Wet Cutting: One of the best practices is wet cutting, which involves using water to suppress dust at the source. This method not only reduces airborne dust but also prolongs the life of the cutting equipment.

-

Vacuum Systems: Using industrial vacuum systems attached to grinders or scarifiers can capture dust directly from the source, minimizing exposure.

-

Regular Cleaning: Keep the work area clean by regularly sweeping or vacuuming to prevent dust accumulation.

Protective Gear

Ensuring safety during repair work requires the right protective gear. This is non-negotiable when dealing with concrete dust and heavy machinery.

-

Respirators: Use N95 respirators or higher-grade masks to protect against inhaling silica dust.

-

Eye Protection: Safety goggles or face shields are essential to protect against flying debris.

-

Hearing Protection: Grinding and cutting can be loud, so earplugs or earmuffs are recommended to prevent hearing damage.

-

Gloves and Protective Clothing: Wear gloves and durable clothing to protect against cuts and abrasions.

Material Selection

Choosing the right materials is crucial for the longevity and effectiveness of the repair.

-

Quality Fillers: Use high-quality concrete fillers that are specifically designed for outdoor use and can withstand weather variations.

-

Adhesives and Primers: Many repair kits include adhesives or primers to improve the bond between the new material and existing concrete. Following manufacturer instructions ensures a strong, durable repair.

-

Compatible Materials: Ensure that any new materials are compatible with existing concrete to prevent future cracking or deterioration.

By adhering to these best practices, you can ensure that your concrete trip hazard repair is not only effective but also safe and compliant with standards. This approach minimizes risks and maximizes the lifespan of your sidewalks, providing peace of mind and safety for all.

Frequently Asked Questions about Concrete Trip Hazard Repair

When it comes to concrete trip hazard repair, there are many questions that homeowners and property managers often have. Let’s address some of the most common questions.

How to remove concrete trip hazard?

Removing a concrete trip hazard effectively requires the right tools and techniques. One popular method is using a scarifier. This tool rapidly removes layers of concrete to level out the surface. Unlike traditional grinders, a scarifier creates a textured surface that is non-slip, which is an added safety benefit.

For more severe hazards, precision cutting techniques can be employed. This method involves cutting the concrete to make it level without the need for complete removal or replacement. It’s a cost-effective solution that saves time and reduces disruption.

What is considered a trip hazard on concrete?

A trip hazard on concrete is typically defined by an elevation change of a quarter-inch or more. These uneven surfaces can cause people to trip and fall, posing a safety risk. According to ADA standards, sidewalks and walkways should be smooth and level to accommodate all users, including those with disabilities.

Ensuring your property meets these standards not only prevents accidents but also helps avoid potential legal liabilities.

Is it better to patch concrete or repair concrete?

Deciding whether to patch or fully repair concrete depends on the extent of the damage and the desired outcome. Patching is a quick fix for minor issues but may not provide a long-term solution. Over time, patched areas can deteriorate, leading to recurring problems.

In contrast, repairing the concrete by leveling and smoothing the surface is a more durable and cost-effective approach. This method addresses the root of the problem, providing a solution that lasts longer and requires less maintenance.

By understanding these key aspects of concrete trip hazard repair, you can make informed decisions that improve safety and compliance on your property.

Conclusion

At Florida Sidewalk Solutions, we specialize in changing hazardous walkways into safe, accessible pathways. Our mission is to ensure that every sidewalk and concrete surface we repair meets ADA compliance standards, making them safe for everyone, including those with disabilities.

Our patented technology sets us apart, providing a more effective and less expensive solution than traditional methods like scabblers or concrete grinders. By cutting the concrete sidewalks to level them, we offer a precise and efficient approach to concrete trip hazard repair. This method not only ensures safety but also maintains the aesthetic appeal of your property.

Choosing Florida Sidewalk Solutions means choosing effective solutions that prioritize safety, compliance, and cost-effectiveness. We believe in creating a harmonious environment where everyone can walk with confidence, free from the worry of tripping hazards.

Let us help you make your sidewalks safer and more accessible. Together, we can turn hazards into harmony.