Why Sidewalk Trip Hazards Are a Critical Safety and Legal Issue

Concrete walkway repairs are essential for safe pedestrian access and avoiding costly liability. As a municipal maintenance manager, you must fix uneven sidewalks that create trip hazards, all while staying on budget and ensuring ADA compliance.

Quick Solutions for Concrete Walkway Trip Hazards:

- Immediate Action Needed: Any vertical displacement over 1/4 inch requires repair per ADA standards.

- Precision Cutting Method: Removes trip hazards without full sidewalk replacement.

- Cost Savings: Up to 75% less expensive than removal and replacement.

- Fast Results: Repairs are completed in hours, not days.

- ADA Compliant: Meets all accessibility requirements immediately.

- Minimal Disruption: No need to close sidewalks or remove existing concrete.

Uneven sidewalks are a major liability. The Americans with Disabilities Act (ADA) defines a ‘trip hazard’ as any vertical change over 1/4 inch, making prompt repair a legal requirement. Concrete leveling can save municipalities up to 75% compared to replacement.

Traditional repair methods like grinding or full replacement are expensive and disruptive. Our patented precision cutting technology offers a cleaner, faster alternative that addresses trip hazards and maintains ADA compliance—without the mess and cost of tearing out concrete. Understanding your repair options for issues caused by tree roots, soil movement, or weather cycles can save money and prevent accidents.

Terms related to Concrete walkway repairs:

Understanding Sidewalk Trip Hazards: Why Repair Matters

An uneven sidewalk slab can catch your toe and send you stumbling. These seemingly minor bumps are “trip hazards”—a serious danger and a significant liability for property owners and municipalities. They aren’t just cosmetic issues; they are safety concerns that require professional concrete walkway repairs to ensure compliance with federal standards.

The stakes are high. According to the Americans with Disabilities Act (ADA), any vertical displacement over 1/4 inch at a joint or crack creates a legal liability. This is federal law, and ignoring these hazards can lead to lawsuits and fines.

Identifying Common Sidewalk Trip Hazards

Knowing what to look for makes trip hazards easier to spot. The main concern is vertical displacement that could cause a fall.

- Uneven slabs are the most common issue, where one section rises or sinks, creating a dangerous lip.

- Heaving occurs when something, usually tree roots, pushes a sidewalk section upward.

- Sinking slabs happen when the soil beneath the concrete erodes or settles, creating depressions.

- Raised joints develop when expansion joints between sections become compromised and their edges lift.

- Cracks with displacement are risky when one side of a crack is vertically higher than the other. Any crack with a height difference needs immediate attention.

What Is a Sidewalk Trip Hazard?

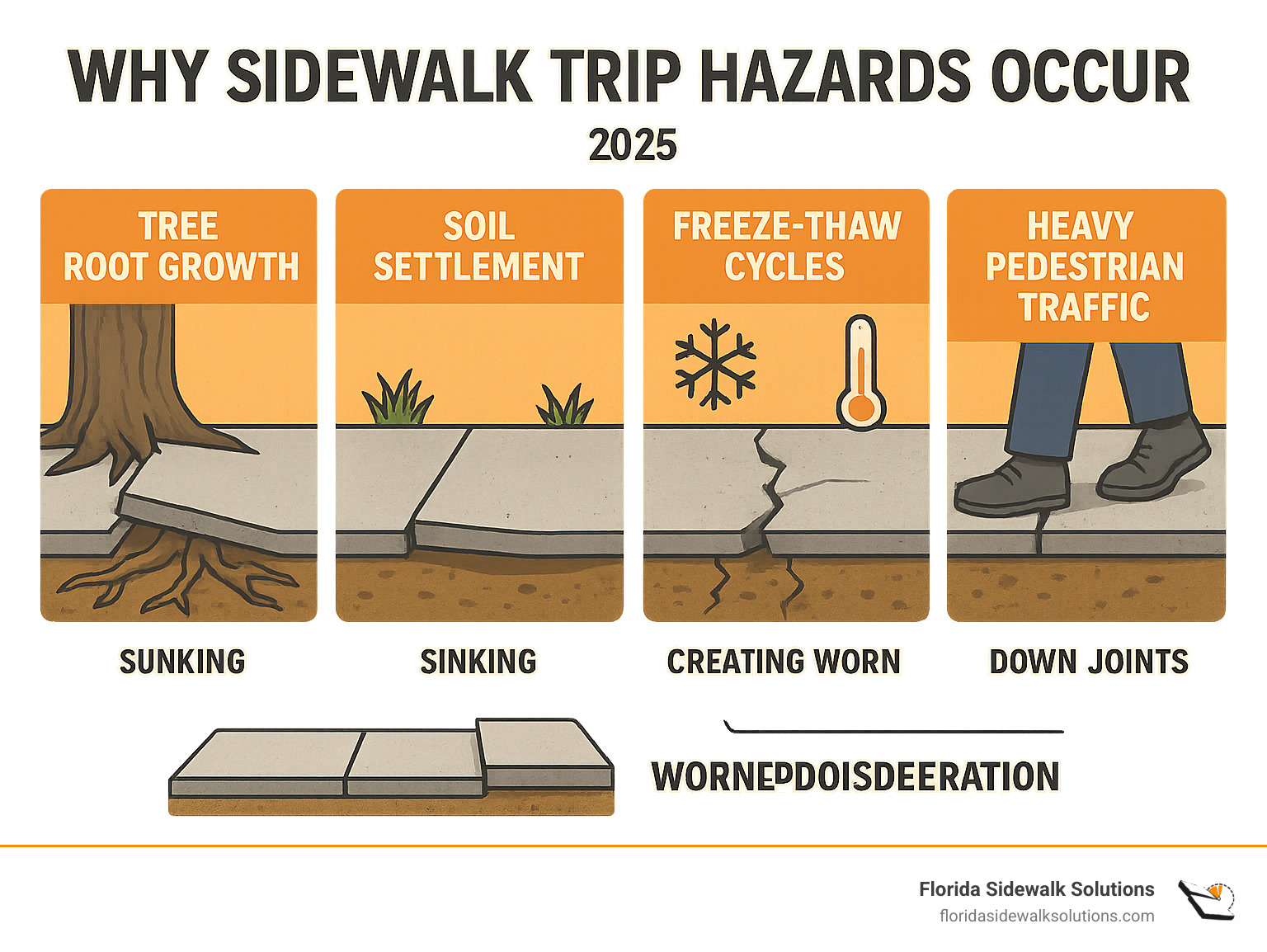

What Causes Sidewalk Trip Hazards?

Understanding the cause helps in making informed repair decisions.

- Soil movement: In Florida’s climate, soil expands and contracts, causing slabs to shift and settle. Poor initial soil compaction creates voids that lead to sinking.

- Tree root growth: Expanding roots exert immense pressure, causing slabs to heave and crack.

- Freeze-thaw cycles: While less common in Florida, water freezing and expanding under concrete can shift slabs over time.

- Heavy foot traffic: Constant use on older sidewalks can worsen existing weaknesses, leading to chipping and unevenness.

- Aging infrastructure: Over decades, exposure and wear degrade concrete, making older systems more prone to displacement issues that require professional concrete walkway repairs.

The good news is that understanding these causes allows for targeted solutions that ensure lasting repairs, keeping pedestrians safe and property owners protected.

A Homeowner’s Guide to Sidewalk Trip Hazard Repairs

When facing an uneven sidewalk, you have options beyond tearing everything out. For trip hazards—any vertical displacement over the ADA’s 1/4-inch limit—you have two main paths: traditional full replacement or our precision cutting method. Full replacement involves demolition and pouring new concrete, while our method repairs your existing sidewalk without the mess and expense.

Here’s how the two approaches compare:

| Feature | Our Precision Cutting Method (Florida Sidewalk Solutions) | Traditional Full Replacement |

|---|---|---|

| Cost-Effectiveness | Significantly more affordable, often saving homeowners and municipalities up to 50-75% compared to replacement. We cut the existing concrete, eliminating demolition and disposal costs. | Most expensive option, involving demolition, removal of old concrete, new material costs, and labor for pouring and finishing. |

| Durability | Provides a long-lasting, permanent repair by precisely leveling the existing concrete. Since the original slab remains, its inherent strength is maintained. A properly done repair can last decades. | A new slab can be very durable, but its longevity depends heavily on the quality of the new concrete, proper base preparation, and curing. |

| Safety Improvement | Immediately eliminates trip hazards by creating a smooth, ADA-compliant transition between uneven slabs. The process is clean and fast, restoring safety within minutes to hours. | Eliminates trip hazards by providing a new, level surface. However, the area is typically cordoned off for at least a day (for curing) and often longer, meaning the trip hazard is present until the new concrete is ready for use. |

| Aesthetics | Maintains the aesthetic consistency of the existing sidewalk, as the original concrete remains. Our cuts are clean and precise, blending seamlessly. | Results in a brand new section of concrete, which may not perfectly match the color or texture of the surrounding older concrete, potentially creating a noticeable patch-work appearance. |

| ADA Compliance | Ensures immediate ADA compliance by leveling changes in elevation to within the 1/4 inch standard or less. This is our core service. | A new pour, if done correctly, will be ADA compliant upon completion. However, the disruption and curing time mean compliance is not immediate. |

| Disruption | Minimal disruption. No heavy machinery, no large-scale demolition, no need to close entire sections of sidewalk for extended periods. Pedestrians can use the sidewalk almost immediately. | Highly disruptive. Involves loud demolition, heavy equipment, significant debris, and often requires closing off the area for days while the new concrete cures. Can impact landscaping. |

| Environmental Impact | Eco-friendly. We don’t generate concrete waste that needs to be hauled to landfills. We reuse the existing material. | Generates significant concrete waste, which must be disposed of, contributing to landfill burden. Requires new concrete production, which has a carbon footprint. |

| Speed | Extremely fast. Repairs can be completed in as little as 15 minutes per section, with almost no waiting time for curing. | Time-consuming. Requires demolition, site preparation, pouring, and then a minimum of a day for initial curing before it can be walked on (and weeks for full cure). |

Our precision cutting approach is faster, cleaner, and easier on your wallet.

Florida Sidewalk Solutions Trip Hazard Repair Process

The Precision Cutting Solution for Trip Hazards

Our approach works smarter, not harder. We solve the problem with the right technology instead of removing the concrete.

Our precision cutting method targets the exact source of the trip hazard. We make a clean, precise cut on the higher slab to create a smooth transition, eliminating the dangerous lip. The dust-controlled process uses specialized equipment to capture dust at the source, keeping your property clean.

Because we don’t remove any of your existing sidewalk, there’s no heavy machinery, no debris hauling, and no waiting for concrete to cure. The minimal disruption is a key benefit; repairs are often done in hours, and the sidewalk is usable almost immediately.

Our fast and clean results provide long-term safety benefits. We eliminate trip hazards permanently, preventing potential injuries and protecting you from liability. This patented technology allows us to offer concrete walkway repairs that are more effective and less expensive than conventional methods.

Step-by-Step: How Florida Sidewalk Solutions Repairs Sidewalk Trip Hazards

Our patented process transforms dangerous, uneven sidewalks into safe, smooth pathways. It’s a precise, safety-focused approach to concrete walkway repairs that delivers lasting results and ensures ADA compliance.

Tools and Technology Used

Our success lies in specialized, cutting-edge equipment that most companies don’t have. We invest in the best technology because your safety deserves it.

- Our precision cutting saws are engineered for accurate, smooth cuts that remove just enough material to create a level transition while maintaining the sidewalk’s structural integrity.

- Our advanced dust control systems capture dust at the source, keeping your property clean and our work environment safe.

- Our trained technicians use comprehensive protective gear and precise measurement tools to ensure every repair meets strict ADA standards.

The Repair Process for Lasting, Compliant Sidewalks

Our streamlined process is designed for minimal disruption.

- Inspection: We start with a thorough inspection, systematically measuring every area of vertical displacement. Any change over 1/4 inch is marked for repair to ensure full ADA compliance.

- Setup: We position our specialized equipment to minimize impact on foot traffic, engaging our dust control systems from the start for a clean work environment.

- Precision Cutting: This is where the magic happens. We make calculated, angled cuts into the higher slab to create a perfectly level transition with the adjacent section, effectively removing the hazard.

- Finishing: We smooth and finish the newly leveled surface to blend seamlessly with your existing concrete, restoring the walkway’s aesthetic appeal.

- Verification and Cleanup: We verify that every repaired section meets or exceeds ADA accessibility guidelines. After a thorough cleanup, the job is complete, leaving a professional-looking result.

This systematic approach delivers concrete walkway repairs that are safe, compliant, and built to last—all while saving you time and money compared to traditional replacement.

Frequently Asked Questions about Sidewalk Trip Hazard Repair

Property owners often have thoughtful questions about concrete walkway repairs. Protecting your investment, ensuring safety, and making smart financial decisions are key. Here are answers to common concerns.

How can I prevent future trip hazards on my sidewalk?

With smart preventive measures, you can reduce the chance of new trip hazards forming.

- Proper drainage: Ensure gutters and downspouts direct water away from sidewalks. Pooled water can erode the soil base, leading to settling.

- Tree root management: Monitor trees near walkways. Consider professional root barriers or strategic pruning if you see signs of lifting. When planting, choose trees with less invasive roots or plant them a safe distance away.

- Regular inspections: Walk your property every few months, especially after heavy rain, to look for small cracks or shifts.

- Prompt repair of new hazards: Addressing minor displacements early is faster and more affordable. Our precision cutting method is ideal for these early-stage issues.

How much do sidewalk trip hazard repairs typically cost?

The cost of concrete walkway repairs varies by method, but traditional approaches are often unnecessarily expensive.

Our precision cutting method offers significant savings—typically 50-75% less than full concrete replacement. We eliminate costly steps like demolition, hauling, and pouring new concrete.

The final price depends on the size and severity of the hazard, the number of problem areas, and accessibility. We provide free, no-obligation estimates so you know the exact cost upfront. Our goal is to provide an effective, economical, and ADA-compliant solution.

When should I hire a professional for sidewalk trip hazard repair?

While the DIY spirit is admirable, sidewalk trip hazards require professional expertise for safety and legal compliance.

- Any vertical displacement over 1/4 inch: This is the ADA’s legal standard for a trip hazard. DIY patches often fail to meet compliance standards.

- Multiple trip hazards: This may signal underlying issues like widespread soil problems. A professional can provide a comprehensive solution.

- ADA compliance requirements: For public or commercial properties, professional repair is non-negotiable. Our method is engineered to meet these standards, protecting you from liability.

- Liability concerns: If someone is injured on your property, you could face legal and financial consequences. Professional repair reduces your risk.

- Need for fast, clean, lasting results: Our service restores safety in hours, not days, with a durable repair designed to last for decades.

Legitimate trip hazards require the precision and specialized equipment that only professional concrete walkway repairs can provide. Our team in South Florida is ready to deliver the effective, economical, and ADA-compliant results you need.

Conclusion

Dealing with uneven sidewalks is a hassle, but as we’ve covered, it’s a critical issue of safety and liability, not just aesthetics. Concrete walkway repairs are about protecting people, preventing accidents, and ensuring your sidewalks are safe and accessible for everyone, in line with the ADA’s 1/4-inch standard.

Florida Sidewalk Solutions understands that traditional replacement is often unnecessary. Our patented precision cutting technology targets the problem directly, creating a smooth, safe transition without the cost, mess, and disruption of replacement.

The benefits are clear: save up to 75% compared to full replacement and have your sidewalk ready for use the same day. You get an ADA-compliant, safe, and attractive walkway without the headaches of a major construction project.

For municipal, commercial, or residential walkways, our precision cutting method delivers lasting safety improvements. We’ve made concrete walkway repairs simple, fast, and affordable.

Ready to transform your uneven sidewalks into safe, compliant walkways? Our team is ready to show you how our patented process can solve your trip hazard problems. Everyone deserves to walk safely.