Why Uneven Sidewalks Demand Immediate Attention

Concrete repair method selection can make or break your sidewalk maintenance budget and safety record. For municipal managers, the right approach means fewer liability claims, lower costs, and smoother pedestrian traffic flow.

Quick Answer: Top Sidewalk Repair Methods

| Method | Best For | Cost | ADA Compliance |

|---|---|---|---|

| Precision Cutting | Trip hazards, uneven joints | Low | Yes |

| Grinding/Scabbling | Surface leveling | Medium | Limited |

| Full Replacement | Severe structural damage | High | Yes |

| Mudjacking | Sunken slabs | Medium | Sometimes |

Uneven sidewalks create more problems than most property managers realize. According to the ADA, any vertical change greater than 1/4 inch qualifies as a trip hazard and opens you up to liability.

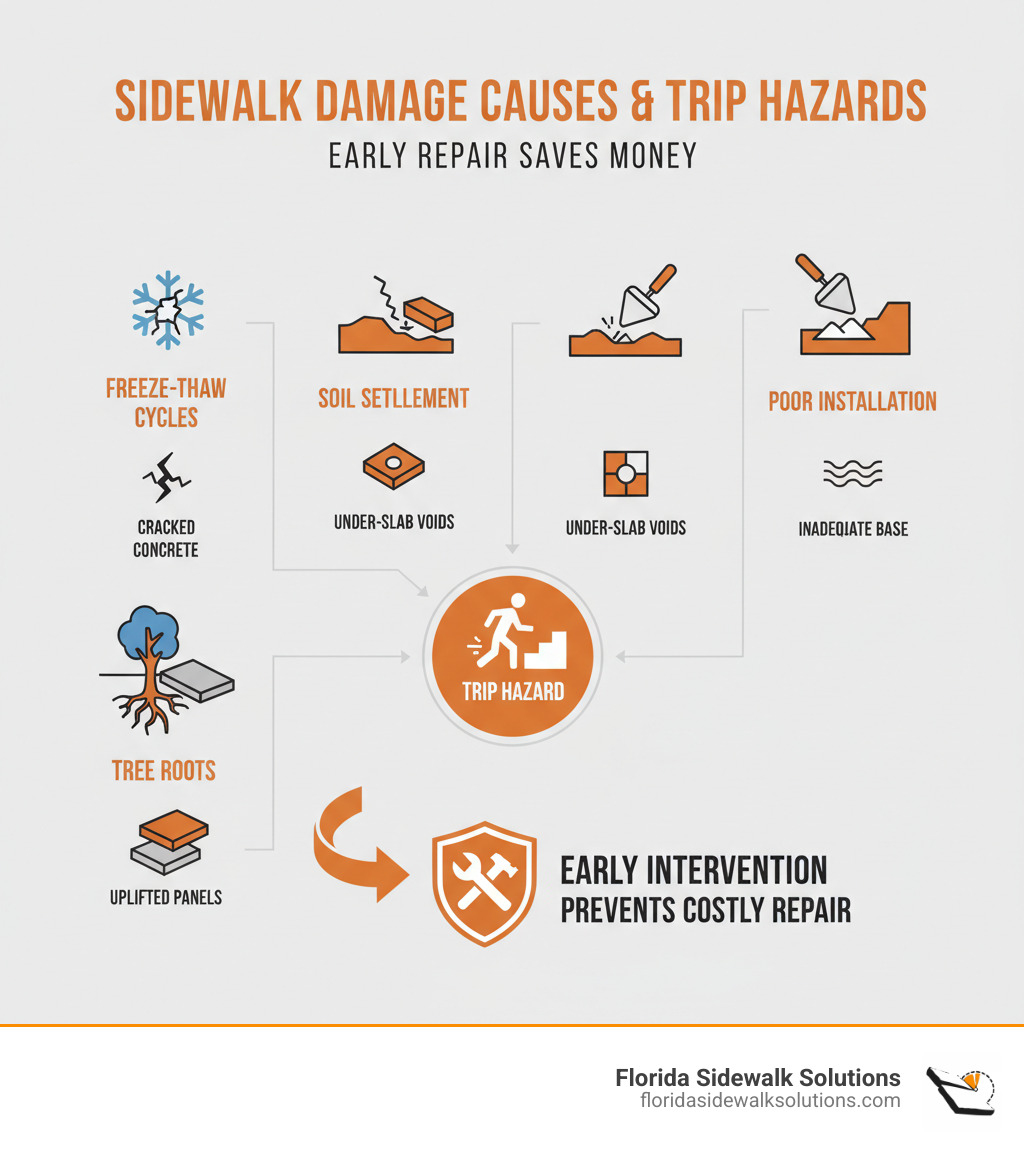

The causes are familiar to anyone managing public walkways:

- Freeze-thaw cycles that crack and lift concrete panels

- Soil settlement beneath slabs creating dangerous drops

- Tree root uplift pushing sections skyward

- Poor installation that shows up years later

Here’s the critical insight most maintenance managers miss: you can’t simply pour new concrete over existing cracks or uneven sections. As one concrete repair guide notes, “any overlay will eventually reflect those cracks due to movement.” The underlying problem remains, and you’ve just wasted money on a temporary fix.

Early repair saves money. Period. A small trip hazard fixed today costs far less than a lawsuit tomorrow, or the expensive full replacement you’ll need after years of neglect. For sidewalks specifically, repair almost always beats replacement in terms of cost, time, and disruption to foot traffic.

The good news? Modern precision cutting methods can level most trip hazards in minutes, not days, at a fraction of replacement costs while maintaining full ADA compliance.

Identifying Common Sidewalk Damage and Its Causes

Walk any sidewalk long enough, and you’ll notice something: concrete doesn’t age gracefully without a little help. Here in Florida, where we spend our days evaluating sidewalks across dozens of municipalities, we see the full spectrum of concrete damage. The good news? Most sidewalk issues can be fixed quickly and affordably when you catch them early. The key is knowing what you’re looking at.

When we evaluate sidewalk conditions, we’re doing more than just spotting cracks. We’re conducting a thorough assessment to identify trip hazards and understand what’s really causing the problem beneath the surface. Think of it as detective work—except instead of solving mysteries, we’re preventing lawsuits and keeping pedestrians safe.

Uneven joints and slabs top our list of concerns, and for good reason. When one concrete panel settles or lifts compared to its neighbor, you’ve got a vertical displacement. ADA guideline we mentioned? Any change in level over 1/4 inch qualifies as a trip hazard. These uneven sections usually happen because of soil settlement (the ground beneath literally sinks), tree root intrusion (those roots are stronger than you’d think), or poor compaction when the sidewalk was first installed.

We also encounter hairline cracks—those thin lines usually less than 1/8 inch wide. They’re often just cosmetic, caused by the concrete drying or normal thermal expansion and contraction. While they won’t trip anyone today, they’re like leaving your door open uped: they invite trouble. Water seeps through these cracks, and that’s when minor problems become major headaches.

Structural cracks are a different beast entirely. These wider, deeper fractures extend through the entire slab and signal serious issues like significant ground movement or structural stress. When these cracks create an uneven surface, you’re looking at both a structural problem and a trip hazard.

Then there’s spalling and surface deterioration—when the concrete surface flakes, pits, or breaks apart. While freeze-thaw cycles cause this in northern climates, we see it in Florida too, usually from poor-quality concrete or improper finishing. Even if spalling doesn’t immediately create a trip hazard, it weakens the concrete and paves the way for bigger problems.

Water infiltration damage deserves special attention. Any crack or joint becomes a doorway for water to sneak beneath your concrete. That water erodes the sub-base, leading to settlement and uneven slabs. Even without freezing temperatures, water erosion quietly undermines your sidewalks.

Finally, root uplift is practically a Florida specialty. Our beautiful trees have aggressive root systems that seek moisture and nutrients, and they don’t mind lifting concrete slabs out of their way. The result? Some of the most dramatic and dangerous trip hazards we encounter.

The pattern is clear: ignore these issues, and you’re looking at expensive repairs or liability lawsuits. Address them early, and you’re looking at quick, affordable fixes.

Assessing the Severity: When to Repair

Not every crack demands immediate action, and not every uneven slab requires the same concrete repair method. The trick is knowing when to repair and when more extensive work might be needed.

Our structural integrity assessment starts with the obvious signs of deterioration. We’re looking at whether the concrete is actively falling apart, whether there’s sound material underneath the damage, and how extensive the problem really is. Here’s what matters most for sidewalk trip hazards:

Cracking patterns tell us a lot. Hairline cracks? Usually manageable. But widespread, deep, or interconnected cracks signal something more serious happening beneath the surface. We pay attention to these patterns because they reveal whether you’re dealing with a surface issue or a deeper structural problem.

Sunken slabs are another key indicator. When a large section of sidewalk has settled significantly, it points to a sub-base issue. Our precision cutting method excels at eliminating the resulting trip hazards, but we’ll also help you understand whether the underlying settlement needs attention for long-term stability.

Spalling and delamination across large areas means the concrete is losing its integrity. Surface material separating or flaking off indicates the slab’s protective layer is failing.

Here’s the reality for sidewalk trip hazards: the cost-benefit analysis almost always favors repair. Full concrete replacement costs more, takes longer, and disrupts pedestrian traffic for days. Our precision cutting method addresses trip hazards in minutes, maintains ADA compliance, and extends the life of your existing concrete—all at a fraction of replacement costs.

We always recommend consulting with a professional if you’re unsure. That’s why we offer free consultations across Florida, from Davie to Fort Lauderdale, Coral Springs to Boca Raton, West Palm Beach to Miami and Fort Myers. We’d rather help you make an informed decision than see you waste money on the wrong solution.

Understanding Cracks and Why You Can’t Just Pour Over Them

“Can’t we just pour new concrete over the cracks?” We hear this question at least once a week, and we get it. A quick overlay sounds perfect—fast, simple, seemingly cost-effective.

Unfortunately, concrete has other plans.

Here’s the thing: concrete moves. It expands when temperatures rise and contracts when they fall. This thermal expansion and contraction happens constantly, even in Florida’s relatively stable climate. Add in the slight shifting of ground beneath the slab, and you’ve got cracks that are actually dynamic. They open and close, subtly but persistently.

When you pour new concrete over these moving cracks, you’re creating a ticking clock. The movement of the underlying slab transfers directly to your new layer. The stress builds. Eventually, the new material cracks directly above the old cracks—a phenomenon called reflective cracking. It’s like putting a fresh bandage over a wound without treating the infection underneath.

The Guide to Concrete Repair confirms what we see in the field: “any overlay will eventually reflect those cracks due to movement.” The new layer won’t adhere properly across a moving crack. The result? Your “repair” fails, often within months.

For cracks that need to move freely, you need flexible solutions. This might mean flexible sealants for non-structural cracks or more advanced techniques for structural issues. But for sidewalk trip hazards—the uneven joints and lifted slabs that create actual dangers—overlays aren’t just ineffective. They’re a waste of your budget.

Sealing versus structural repair addresses different problems. Sealing prevents water infiltration through hairline cracks. Structural repair—like our precision cutting method—addresses the actual trip hazards created by uneven surfaces. Understanding this difference is crucial for selecting the right concrete repair method.

We believe in solutions that last. That means understanding how concrete actually behaves and choosing repair methods that work with that behavior, not against it. For sidewalk trip hazards specifically, precision cutting eliminates the hazard without fighting concrete’s natural movement—which is exactly why it works so well.

The Florida Sidewalk Solutions Precision Cutting Method

We’ve spent years watching property managers struggle with uneven sidewalks, trying method after method only to see the same trip hazards return. That’s why we developed something different at Florida Sidewalk Solutions. Our concrete repair method isn’t borrowed from anyone else—it’s our own patented technology, built specifically to solve the sidewalk trip hazard problem once and for all.

Here’s what makes us different: we don’t grind your sidewalks into submission, leaving rough surfaces and inconsistent results. We don’t use scabblers that scar up your concrete assets. And we certainly don’t recommend tearing out and replacing perfectly good concrete just because one edge is higher than another. Instead, we cut with surgical precision, creating smooth transitions that eliminate trip hazards while keeping your existing sidewalk intact.

Our method was designed with property managers in mind—people in Davie, Fort Lauderdale, Coral Springs, Boca Raton, West Palm Beach, Miami, and Fort Myers who need their sidewalks safe, compliant, and budget-friendly. We understand that liability claims and repair costs keep you up at night. Our precision cutting addresses both concerns head-on.

How Precision Cutting Works

Think of our method as a highly specialized form of concrete surgery. Instead of removing an entire section of sidewalk—which creates waste, costs money, and disrupts foot traffic for days—we carefully cut a precisely measured ramp directly into the higher concrete panel. This creates a smooth, safe transition down to the lower section, effectively erasing the vertical displacement that creates trip hazards.

The magic happens through horizontal cutting. Our specialized equipment makes a controlled cut that creates an ADA-compliant slope, feathering the edge down to zero. It’s not unlike planing wood, except we’re working with concrete and achieving accuracy measured in fractions of an inch.

What makes our equipment special? It reaches places traditional grinders simply cannot access. Those tricky spots near gutters, tight corners against walls, edges adjacent to building foundations—our machine handles them all. We can adjust the cut depth and angle on the fly, ensuring every repair meets exact ADA requirements for slopes. The result is a smooth, level transition that looks like it was always meant to be there.

The benefits speak for themselves. Our repairs are ADA-compliant every single time because we’re cutting to precise specifications, not eyeballing it with a grinder. We’re cost-effective because we’re not hauling away good concrete and pouring new material. There’s no waiting for concrete to cure, no multi-day closures, no extensive demolition. Just quick, clean cuts that solve the problem.

The minimal disruption is something our clients love. We can often complete a repair in minutes, and pedestrians can walk on the surface almost immediately. Compare that to replacement projects that close sidewalks for days while concrete cures. For busy walkways in downtown Fort Lauderdale or Miami, that difference matters.

From an environmental standpoint, we’re drastically reducing concrete waste. Every sidewalk we repair instead of replace keeps hundreds of pounds of concrete out of landfills. It’s a greener approach that still delivers superior results.

Here’s the truth many organizations find the hard way: conventional methods often mean doing the job twice. Grinders leave inconsistent surfaces that don’t fully eliminate hazards. They create rough patches that don’t meet ADA slope requirements. They damage the surrounding concrete. Then, a year or two later, you’re back to square one, spending money again to fix what should have been done right the first time.

Our precision cutting method solves it right the first time. It’s why we confidently say our approach is superior for sidewalk trip hazard removal. We’re not just making your sidewalks flatter—we’re making them safer, compliant, and built to last.

A Step-by-Step Guide to Sidewalk Trip Hazard Removal

When you partner with Florida Sidewalk Solutions, you’re choosing a proven, efficient process that transforms dangerous sidewalks into safe, compliant walkways. Our concrete repair method isn’t just about cutting concrete—it’s about delivering precision, safety, and lasting results. Here’s exactly how we make it happen.

Step 1: Site Preparation and Safety

Before we even power up our equipment, we take the time to prepare your site properly. Safety isn’t just a checkbox for us—it’s the foundation of every job we complete.

Our team arrives ready to work, assessing the immediate environment and noting any potential challenges. We start by marking the hazard clearly, measuring the vertical displacement to confirm it exceeds ADA thresholds and needs repair. This focused approach ensures we address every problem area without wasting time or resources.

Debris containment comes next. While our precision cutting generates far less mess than traditional grinding or demolition, we still take steps to keep your property clean. We contain the work area to prevent any concrete dust from spreading to adjacent properties or walkways.

Our technicians wear full Personal Protective Equipment (PPE)—eye protection, hearing protection, and safety footwear are non-negotiable. We follow strict safety protocols because a hazard-free work environment protects everyone: our team, your pedestrians, and your property.

When needed, we establish clear traffic and pedestrian control measures. Simple signage and temporary barriers guide foot traffic safely around our work area, minimizing disruption while keeping everyone safe. For those interested in the broader context of concrete repair safety standards, the 546R-96 Concrete Repair Guide offers comprehensive best practices.

Step 2: The Cutting Process

This is where our patented technology truly transforms a dangerous sidewalk into a safe, smooth walkway. It’s precision engineering at its finest.

Our specialized sidewalk cutting machine gets carefully positioned over the identified trip hazard. This isn’t your typical concrete equipment—it’s designed specifically for stability and pinpoint accuracy. Setting up the equipment properly is crucial because even a slight miscalculation could compromise the repair.

Next, our trained technicians adjust the cut depth and angle to exact specifications. We’re creating an ADA-compliant ramp that eliminates the vertical differential entirely, and that requires precise programming. The machine needs to know exactly how deep to cut and at what angle to create that gentle, safe slope.

The horizontal cut itself is remarkably smooth. Unlike rough grinding that scars up your sidewalk, our method delivers a clean, controlled cut that shaves down the lifted section. It’s efficient, relatively quiet, and far less disruptive than traditional methods. Property managers across Florida—from Davie to Fort Lauderdale to Miami—appreciate how quickly we work.

As the machine moves, it creates a smooth, uniform slope with no residual bumps or unevenness. We’re not just removing the hazard; we’re creating a seamless transition between concrete panels. The final touch is feathering the edge to zero at the lower panel, meaning our new ramp meets the existing surface so smoothly you’d hardly know there was ever a problem.

This meticulous attention to detail is what separates our concrete repair method from conventional approaches. We’re not just fixing sidewalks—we’re restoring them to better-than-original condition.

Step 3: Cleanup and Final Inspection

The cutting might be done, but we’re not finished until your sidewalk is clean, safe, and fully documented.

Debris removal and disposal happens immediately. We collect all concrete dust and small particles generated during cutting and dispose of them responsibly according to local environmental regulations. Because our method produces significantly less waste than demolition or grinding, cleanup is faster and more eco-friendly. Your property looks pristine when we leave.

Our technicians then carefully evaluate the repair, running their hands over the transition, visually inspecting the slope, and using levels or measuring tools to confirm accuracy. We’re checking for any imperfections that might have been missed during the cutting process.

Verifying ADA compliance is non-negotiable. We ensure the repaired section meets all requirements for changes in level and slope. This verification protects you from liability and gives you the peace of mind that comes with knowing your sidewalks are legally compliant. For property managers responsible for public walkways, this documentation is invaluable.

We walk over the repaired area ourselves, testing for a smooth, trip-free surface. If we wouldn’t confidently walk our own family members across it, it’s not ready. The ultimate measure of success is a sidewalk that’s not just compliant but genuinely safe.

Finally, we provide documentation of the repair for our clients across Florida—whether you’re in Coral Springs, Boca Raton, West Palm Beach, or Fort Myers. This includes before-and-after photos that prove the repair was completed properly. These records are essential for your maintenance files and can be critical if liability questions ever arise.

When we drive away, you’re left with a sidewalk that’s safer, compliant, and ready for years of reliable service. That’s the Florida Sidewalk Solutions difference.

Frequently Asked Questions about Sidewalk Repair

Property managers and community associations throughout Florida often reach out to us with questions about keeping their sidewalks safe and compliant. After years of repairing trip hazards from Davie to Fort Myers, we’ve learned what concerns you most. Let’s tackle the big questions.

How can I tell if my sidewalk is ADA compliant?

Here’s the truth: if you can feel a lip when you run your hand across a sidewalk joint, there’s a good chance it’s not compliant. And that means liability risk.

The Americans with Disabilities Act isn’t vague about this. Any vertical change greater than 1/4 inch (about the thickness of two stacked pennies) qualifies as a trip hazard and violates ADA guidelines. That’s not much at all, which is why so many sidewalks across Florida have compliance issues.

Between 1/4 inch and 1/2 inch, you need a beveled slope no steeper than 1:2. Think of it this way: for every inch of height difference, you need two inches of gradual ramp. Anything over 1/2 inch requires an even gentler 1:12 slope, which means you need a full foot of ramp for every inch of rise.

The importance of a smooth transition goes beyond just meeting legal requirements. It’s about keeping people safe, whether they’re using a wheelchair, pushing a stroller, or simply walking and texting (we’ve all done it). Our precision cutting concrete repair method creates these exact compliant slopes, protecting both pedestrians and your organization from trip hazard liability.

What is the most cost-effective sidewalk trip hazard repair method?

Let’s be honest about costs, because we know your budget matters.

Full replacement is the expensive option everyone dreads. You’re paying for demolition crews, hauling away tons of concrete, preparing the base, pouring new material, and then waiting days for it to cure. For a simple trip hazard? That’s like buying a new car because you have a flat tire. The costs add up fast, especially when you’re dealing with multiple locations across your property.

Traditional grinding and scabbling methods fall somewhere in the middle price-wise, but here’s what many property managers find too late: they often don’t fully solve the problem. These methods can leave inconsistent surfaces, create unsightly scars on your sidewalk, and frequently fail to create truly ADA-compliant slopes, especially at the edges and corners. You might save money upfront, only to face liability issues or need rework later.

Our precision cutting method is the budget-friendly alternative that actually works. We’re not just saying this because it’s our service—the numbers speak for themselves. By targeting only the specific hazard with a precise, horizontal cut, we eliminate the waste, excessive labor, and extended downtime that drive up costs with other methods. You’re paying for exactly what you need: a safe, compliant surface that eliminates liability and extends the life of your existing concrete.

The long-term value is even better. A properly executed precision cut lasts, meaning you’re not calling us back next year to fix the same spot. That’s real cost-effectiveness.

How long does a sidewalk repair take?

Time is money, and pedestrian access matters. Let’s break down what you’re looking at with different repair approaches.

Full replacement projects stretch across multiple days or even weeks. There’s the demolition day, the hauling day, the base preparation, the concrete pour, and then the real killer: the curing period. You’re typically looking at seven days minimum before allowing full foot traffic, and longer for any heavy use. That’s a week of barricades, detours, and frustrated pedestrians.

Traditional grinding or scabbling methods move faster than replacement but still require several hours per section when you factor in setup, the actual work, and cleanup. For a property with multiple trip hazards, you could be looking at a full day or more of disruption.

Here’s where our concrete repair method changes the game: most individual trip hazards are repaired in minutes, not hours or days. Our specialized equipment allows for rapid setup and precise execution. The pedestrian access is restored almost immediately—no waiting for concrete to cure, no extended closures.

For municipalities and property managers across Florida managing dozens or even hundreds of trip hazards, this efficiency is transformative. We can address multiple hazards across a large property in a single day, with minimal disruption to your residents, customers, or foot traffic. That’s the kind of speed that keeps your operations running smoothly while keeping people safe.

Conclusion: Choosing the Right Solution for Safe, Lasting Repairs

We’ve covered a lot of ground today—from identifying what makes a sidewalk unsafe to understanding why you can’t just slap a quick fix over existing problems. The truth is, when it comes to sidewalk trip hazards, choosing the right concrete repair method makes all the difference between a temporary patch and a solution that actually lasts.

Here’s what we know for certain: uneven sidewalks aren’t just unsightly. They’re liability waiting to happen. But the good news? You don’t need to break the bank with expensive demolition and replacement to fix them. You just need the right approach.

Our precision cutting method addresses trip hazards exactly where they occur, creating smooth, ADA-compliant transitions that keep pedestrians safe and your property protected. Unlike methods that leave inconsistent results or fail to meet compliance standards, our patented technology delivers durability and longevity you can count on. We’re talking about repairs that stand the test of time, not temporary fixes that need redoing next year.

The ADA compliance benefits alone make precision cutting worthwhile. When every repair meets the exact standards required by law, you’re not just fixing a problem—you’re eliminating liability. For property managers across Florida, from the sidewalks of Davie to the walkways of Miami, that peace of mind is invaluable.

We started Florida Sidewalk Solutions because we saw too many properties spending money twice—once on a method that didn’t work, and again to fix it properly. Our goal has always been simple: do it right the first time, save you money, and keep people safe.

If you’re managing sidewalks anywhere from Fort Lauderdale to Fort Myers, and you’re tired of dealing with trip hazards that keep coming back, we’d love to show you what precision cutting can do. Learn more about our Florida sidewalk cutting company and find how we’re making walkways safer, one smooth cut at a time.