Why Grinders Fall Short for Serious Sidewalk Trip Hazards

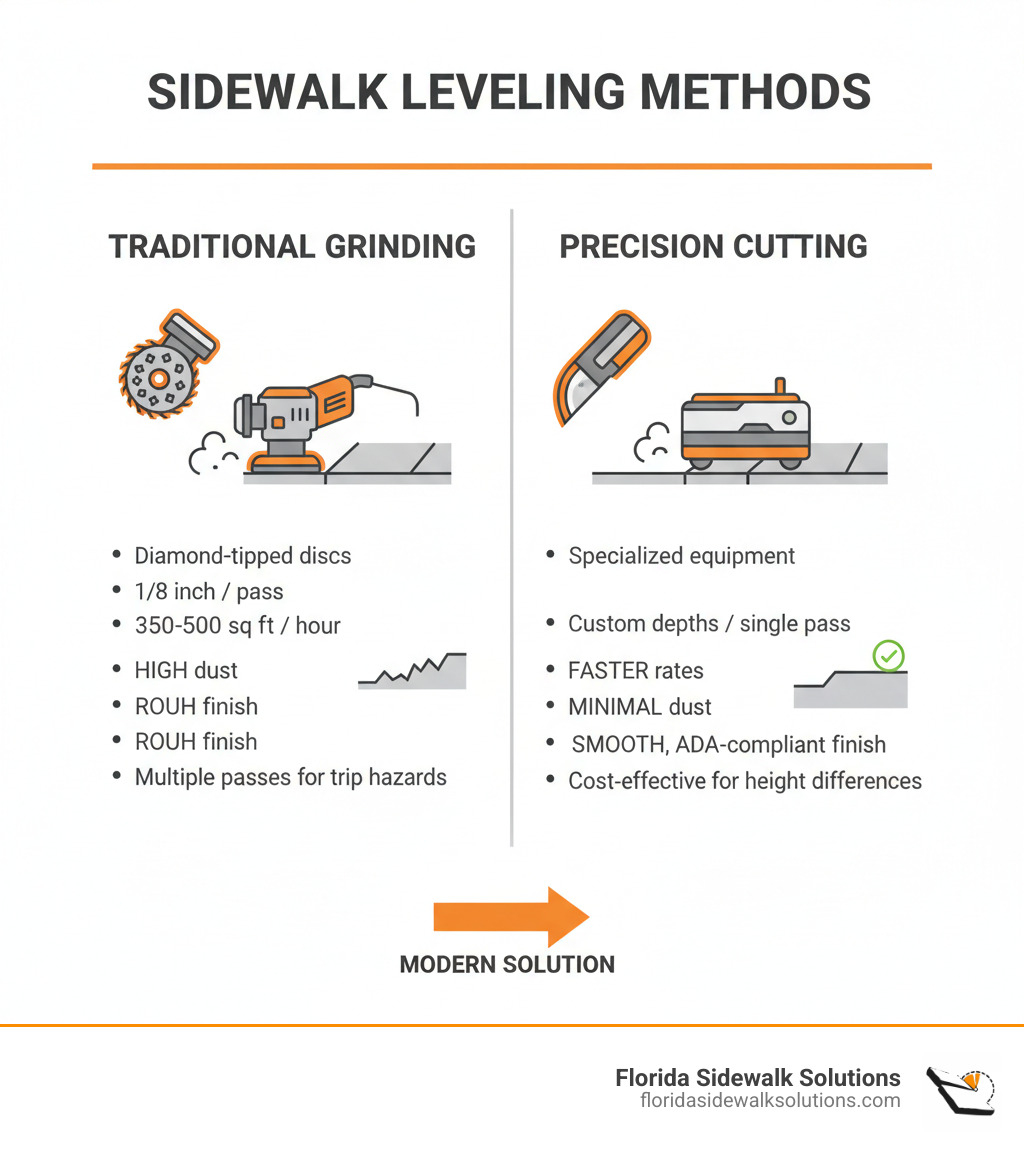

A grinder for shaving down a concrete sidewalk uses rotating diamond-tipped discs to remove shallow layers of concrete, about 1/8 inch per pass. While effective for minor surface imperfections, grinders are often too slow and labor-intensive for significant trip hazards that require ADA compliance.

Quick Answer: Grinders vs. Precision Cutting for Sidewalk Repair

| Method | Best For | Depth Per Pass | Cost-Effectiveness | ADA Compliance |

|---|---|---|---|---|

| Concrete Grinder | Minor imperfections, smoothing rough textures | Up to 1/8 inch | Slow, labor-intensive | Limited for major hazards |

| Precision Sidewalk Cutting | Trip hazard removal, ADA compliance | Custom depth | Fast, economical | Ideal solution |

As a Municipal Maintenance Manager, you need to keep sidewalks safe without exceeding your budget. Uneven concrete creates trip hazards, exposing your municipality to liability claims. You need solutions that are fast, durable, and cost-effective.

While traditional grinding can smooth surfaces, it becomes painfully slow for height differences over 1/4 inch—the ADA’s maximum for vertical displacement. Grinding at a typical rate of 350-500 square feet per hour (at 1/8 inch depth) requires multiple passes for major hazards. This means more dust, traffic disruption, and labor costs. In contrast, specialized precision sidewalk cutting achieves the same result in a fraction of the time with minimal disruption.

This guide explains how concrete grinders work, when to use them, and why precision cutting is often a better choice for serious trip hazard removal and ADA compliance.

What is a Concrete Grinder and How Is It Used for Sidewalk Repair?

A concrete grinder is like a massive sander for concrete. It uses rotating diamond-tipped discs to abrade the surface, removing thin layers to create a smoother finish. Unlike tools that chip away at concrete, grinders operate with a lighter touch.

The diamond-tipped discs gradually wear down high spots. In a single pass, a grinder typically removes up to 1/8 inch of material, which is why it’s best for minor surface issues.

For sidewalk maintenance, a grinder for shaving down a concrete sidewalk can smooth rough textures, remove old sealants, or address very slight height differences. However, for actual trip hazards that violate ADA standards, grinders show their limitations.

Let’s break down how these methods compare for trip hazard repair:

| Feature | Concrete Grinder | Precision Sidewalk Cutting |

|---|---|---|

| Removal Method | Abrasive diamond discs | Specialized cutting blade |

| Depth of Removal | Up to 1/8 inch per pass | Custom, precise depth in a single pass |

| Surface Finish | Smooth, can be polished | Smooth, uniform, ADA-compliant |

| Speed/Efficiency | Slow, multiple passes for trip hazards | Fast, single pass for most trip hazards |

| Dust Production | High, even with collection | Minimal |

| Labor Intensity | High, physically demanding | Low, machine-operated |

| Cost for Trip Hazards | Higher due to labor and time | Lower due to efficiency |

| ADA Compliance | Limited for significant hazards | Excellent, designed for compliance |

| Best For | Minor imperfections, surface prep | Significant trip hazards, large-scale leveling |

When to Use a Grinder for Sidewalks

While we specialize in more effective solutions, grinders have their place. They work well for minor imperfections like slight surface blemishes or small bumps that aren’t true trip hazards. A grinder can also smooth a rough texture, remove thin coatings like paint, or prepare surfaces for a new overlay. For very slight unevenness (1/8 inch or less), a grinder can create a gradual slope. The key word is minor.

When Precision Sidewalk Cutting Is a Better Choice

In our work across Davie, Fort Lauderdale, Coral Springs, Boca Raton, West Palm Beach, Miami, and Fort Myers, we find most trip hazards need more than a grinder can offer.

- Significant Trip Hazards: For height differences over 1/4 inch, grinding is inefficient. It requires multiple passes, increasing labor hours and sidewalk disruption. Our precision cutting technology handles these in a single pass.

- ADA Compliance: Achieving the precise, gradual slopes required by the ADA is difficult with a grinder. Our patented method is engineered to meet these requirements, ensuring public safety and reducing liability.

- Smooth, Uniform Finish: Grinding can result in an uneven, undulating surface. Precision cutting creates a clean, consistent ramp that is safer for pedestrians.

- Minimal Dust and Disruption: Grinding creates significant airborne silica dust and requires longer work periods. Our specialized equipment minimizes both issues.

- Cost-Effectiveness: When you factor in labor, equipment wear, and time, precision cutting delivers more cost-effective, long-lasting results. It’s a durable repair that reduces future maintenance and liability risks.

Key Features to Look for in a Grinder for Sidewalk Repair

If you need to use a grinder for shaving down a concrete sidewalk for minor touch-ups, understanding the key features will help you choose the right tool.

- Walk-behind vs. Handheld: Walk-behind grinders are best for larger areas, offering more power and consistency. For tight spots like corners or around utility covers, a handheld grinder is essential. Handheld models typically use 5-inch discs for maneuverability or 7-inch discs for more coverage.

- Power Source: Electric grinders are quieter, produce no fumes, and are ideal when outlets are available. Gasoline or propane models offer portability for remote locations but require ventilation and are noisier.

- Motor Power: Look at amperage (Amps) and RPM. Higher amperage (e.g., 12.5 amps) provides more muscle to prevent bogging down. Higher RPM (7,000-9,300) means faster material removal but requires more operator skill.

- Variable Speed Control: This feature allows you to adjust the grinder’s speed for delicate work or aggressive removal, offering better control over the final finish.

The Critical Role of Dust Collection

Grinding concrete generates fine crystalline silica dust, a serious health hazard. Inhaling it can lead to incurable diseases like silicosis and lung cancer. OSHA regulations require strict controls to protect workers.

Integrated dust shrouds are essential safety equipment, not optional accessories. These shrouds fit around the grinding disc and capture dust at the source. They have vacuum ports that connect to an industrial vacuum.

It is critical to use a HEPA-filtered vacuum. Standard shop vacs cannot capture the microscopic silica particles, which will pass through the filter and back into the air. A HEPA filter traps these particles, creating a “virtually dust-free operation” that keeps your crew and the public safe.

Effective dust collection also means a cleaner work environment, less disruption to nearby businesses, and faster cleanup. Understanding chemical exposure warnings related to silica is a vital part of operating safely.

The Step-by-Step Process for Grinding a Sidewalk

If you decide a grinder for shaving down a concrete sidewalk is right for a minor issue, follow these steps. For significant trip hazards, our precision cutting method is faster, more economical, and more effective.

Project Preparation

Proper preparation is key. First, identify and mark the problem areas with chalk. Next, clear the work zone of all debris, dirt, and obstacles. A clean surface is essential, so sweep and, if possible, power wash the concrete. Finally, gather your grinder, diamond cups, HEPA vacuum system, and all safety gear.

Grinding Technique

Patience is crucial. Use light, steady passes, letting the grinder’s weight do the work. Pushing too hard creates an uneven surface and wears out equipment. Overlap each pass to ensure even material removal and avoid ridges.

To create a safe transition on a raised section, use a technique called “feathering.” Gradually reduce pressure as you move away from the main grinding area to create a smooth, tapered slope. Stop frequently to vacuum the dust and check your progress with a straightedge to avoid over-grinding.

Cleanup Process

Your HEPA vacuum should run constantly to capture dangerous silica dust at the source. After grinding, thoroughly vacuum the entire work area, including cracks and edges, to capture any residual dust. Some contractors rinse the area with water, ensuring the runoff does not enter storm drains.

Safety First: Essential Precautions for Grinding Concrete

Operating a grinder creates serious hazards. Protecting yourself is mandatory.

- Personal Protective Equipment (PPE): Always wear an N95 or P100 respirator to protect against silica dust. Also essential are safety glasses/goggles, hearing protection, heavy-duty gloves, and steel-toed boots.

- Dust Control: The most critical safety measure is using a grinder with an integrated dust shroud connected to a HEPA-filtered vacuum. This minimizes airborne silica, a known carcinogen. Understanding chemical exposure warnings is part of responsible operation.

- Site Safety: If using an electric grinder, ensure the power cord is in good condition and use a GFCI. Keep cords and hoses clear to prevent tripping hazards, and keep bystanders away from the work zone.

How to Use a Grinder for Shaving Down a Concrete Sidewalk Trip Hazard

To address a trip hazard, you must create a smooth, gradual transition. However, grinders struggle to achieve ADA compliance for anything beyond minor height differences.

First, measure the height difference. The ADA allows a maximum 1/4-inch vertical lip, or up to 1/2-inch if beveled at a slope no steeper than 1:2. For anything more, a grinder is the wrong tool.

Begin grinding several inches back from the raised edge to create a gradual slope. Use the feathering technique, working toward the edge while slowly reducing the height. Check your work constantly with a 4-foot level to ensure a smooth transition.

The challenge is achieving the ADA-compliant slope, which should not exceed 1:12 (1 inch of rise for every 12 inches of run). This precision is extremely difficult and time-consuming with a handheld grinder. While a grinder can reduce a hazard, our precision cutting method is engineered to meet these exact specifications reliably, providing a compliant solution for communities like Davie, Fort Lauderdale, and Miami.

Limitations of Using a Grinder for Shaving Down a Concrete Sidewalk

While a grinder for shaving down a concrete sidewalk seems like a straightforward solution, it has serious limitations for real trip hazards, a reality we see daily in our work with Florida municipalities.

- Slow Removal Rate: A grinder removes only 1/8 inch of concrete per pass. Significant trip hazards require multiple passes, consuming time, wearing out expensive diamond discs, and causing prolonged sidewalk disruption. This slow pace is inefficient for managing miles of sidewalk in cities like Davie or Fort Lauderdale.

- Potential for Uneven Finish: Achieving a truly smooth, level finish with a grinder requires significant skill. It’s easy to create dips and waves, trading one hazard for another and failing to meet ADA standards.

- Impractical for Large Height Differences: For trip hazards of a half-inch or more, grinding is impractical. The volume of material to be removed makes the process unrealistic, exhausting crews and equipment without guaranteeing an ADA-compliant result.

- High Dust Production: Even with advanced dust collection, grinding generates substantial silica dust. This requires strict safety protocols and creates a nuisance for the public on busy sidewalks in places like Coral Springs or Boca Raton.

- Labor-Intensive Process: Operating a grinder is physically demanding due to vibration and the need for constant pressure. This leads to higher labor costs and crew fatigue, increasing safety risks.

- The Real Cost: The perceived economy of grinding is misleading. When you factor in rental fees, replacement diamond cups (starting at $240+), extensive labor hours, and dust control, the total cost becomes significant. Our precision cutting method was developed to provide a faster, cleaner, and more cost-effective solution that delivers genuine ADA compliance.

Conclusion: The Best Path to a Safe, ADA-Compliant Sidewalk

We’ve seen that a grinder for shaving down a concrete sidewalk is useful for minor cosmetic work like smoothing rough textures or removing thin coatings.

However, for real trip hazards that create liability risks, grinders fall short. The slow 1/8-inch removal rate, excessive dust, and difficulty in achieving a precise, ADA-compliant finish make them an inefficient solution for significant repairs.

Florida Sidewalk Solutions was founded to fill this gap. We saw municipal managers in Davie, Fort Lauderdale, Coral Springs, and across Florida stuck between slow grinding and costly replacement.

Our patented precision sidewalk cutting method is the answer. It removes trip hazards in a single pass, creates a perfect ADA-compliant slope every time, produces minimal dust, and is far more cost-effective than grinding or replacement.

ADA compliance is about ensuring everyone in your community can use sidewalks safely. This requires a level of precision that grinding struggles to provide for substantial trip hazards.

Your sidewalks connect your community and deserve a repair solution that is effective, economical, and reliable. If you’re ready for a better alternative to inadequate repairs and budget-breaking replacements, we can show you what precision cutting can do. Learn about a more effective sidewalk cutting solution designed for the challenges you face.