Is Sidewalk Grinding Worth It vs. Replacement? The Truth About Concrete Repair Options

When faced with uneven, hazardous sidewalks, property managers and facility directors often rush to evaluate two common repair methods: grinding and full replacement. However, this comparison misses a critical third option that delivers superior results at a fraction of the cost. Understanding the real limitations of sidewalk grinding—and why it falls short compared to advanced cutting technology—can save your organization tens of thousands of dollars while providing better, longer-lasting outcomes.

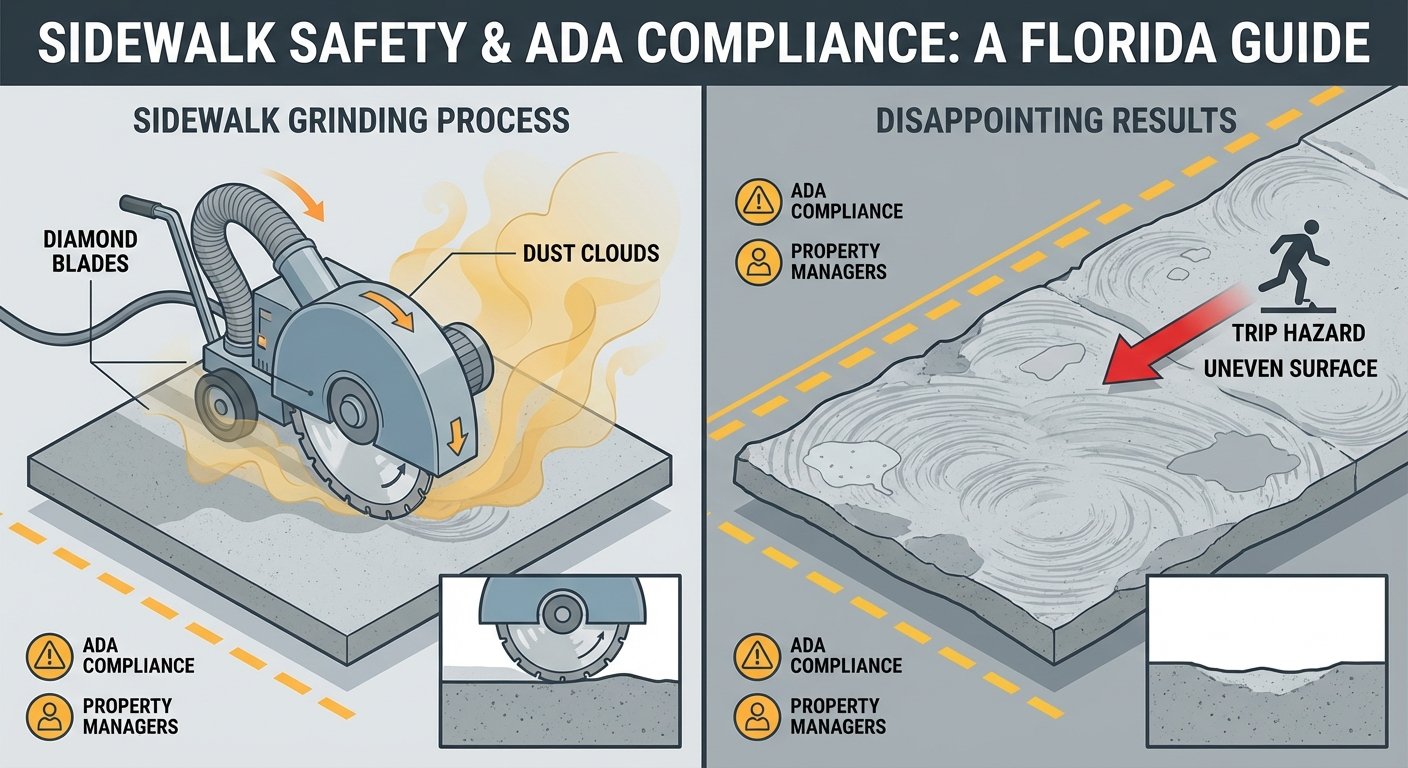

The Reality of Traditional Sidewalk Grinding

Sidewalk grinding involves using abrasive equipment to reduce the height of raised concrete sections, theoretically creating a smoother transition. While this approach sounds practical and cost-effective on the surface, the results often disappoint property managers who expect a professional, permanent solution.

The grinding process leaves behind a rough, textured surface that contrasts sharply with the smooth finish of surrounding concrete. This aesthetic inconsistency becomes particularly problematic for commercial properties, upscale residential communities, and municipalities focused on maintaining professional appearances. The abraded surface also creates ongoing maintenance challenges, collecting dirt and debris more readily than smooth concrete.

ADA Compliance Issues with Grinding

More concerning than aesthetics, grinding frequently fails to achieve true ADA compliance. The Americans with Disabilities Act requires vertical height differences in walkways not to exceed 1/4 inch for accessibility. While grinding can reduce height differentials, it often leaves irregular surfaces that may technically measure within compliance but create difficult conditions for wheelchair users and individuals with mobility challenges.

The rough texture left by grinding equipment can catch wheelchair wheels and create resistance that makes navigation difficult. For property managers responsible for facilities that serve the public, this limitation exposes organizations to ongoing liability concerns even after investing in what they believed was a corrective repair.

The High Cost of Sidewalk Replacement

When grinding proves inadequate, many decision-makers consider complete sidewalk replacement as the only remaining option. This approach certainly eliminates trip hazards and creates uniform surfaces, but the financial and operational costs often shock budget-conscious organizations.

Sidewalk replacement cost in Florida typically ranges from $8 to $15 per square foot, depending on location, accessibility, and project scope. For a commercial property with just 1,000 square feet of problematic walkways, replacement costs can easily exceed $12,000. Municipal projects involving miles of sidewalks face six-figure price tags that strain already tight public works budgets.

Hidden Expenses of Replacement

The per-square-foot price represents only part of the total expense. Replacement projects generate substantial additional costs:

- Demolition and hauling: Removing existing concrete and transporting debris to disposal facilities adds 20-30% to project costs

- Extended downtime: Replacement requires several days for demolition, forming, pouring, and curing—often 5-7 days before walkways become accessible again

- Landscaping damage: Heavy equipment and demolition work frequently damages adjacent landscaping, sprinkler systems, and edging

- Business interruption: Restricted access to storefronts, building entrances, or amenities impacts revenue and resident satisfaction

For HOA board members answering to budget-conscious homeowners, or facilities managers working within fixed annual allocations, these expenses make replacement financially impractical for all but the most severely damaged concrete.

Why Most Sidewalks Don’t Actually Need Replacement

Here’s the critical insight that changes the entire repair equation: the vast majority of trip hazard situations involve structurally sound concrete that has simply shifted due to soil settling, root growth, or erosion. The concrete itself remains in excellent condition—it’s just no longer level.

Replacing perfectly good concrete simply because it has become uneven makes as little economic sense as demolishing a house because the front steps need repair. Yet this wasteful approach continues because property managers often don’t know about superior alternatives that address the leveling issue directly.

Precision Cutting: The Superior Sidewalk Grinding Alternative

Advanced concrete cutting technology transforms the trip hazard repair equation by addressing the fundamental problem—height differential—with surgical precision. Unlike grinding, which removes material through abrasion, precision cutting uses specialized diamond-blade equipment to create clean, beveled transitions that meet or exceed ADA standards.

This patented approach has revolutionized sidewalk leveling in Florida and across the country, providing results that grinding cannot match and replacement cannot justify economically.

How Precision Cutting Works

The process involves deploying specialized cutting equipment that creates precise beveled transitions at the exact angles required for ADA compliance. Technicians measure height differentials and calculate the optimal bevel distance to create a smooth, safe transition that eliminates the trip hazard completely.

The cutting process produces a clean, professional finish that matches the appearance of the surrounding concrete. There’s no rough texture, no visible scarring, and no aesthetic compromise. The result looks intentional rather than remedial—an important consideration for properties where appearance matters.

Cost Comparison: The Numbers That Matter

For decision-makers evaluating options for concrete sidewalk repair, the financial advantages of precision cutting become immediately apparent:

Typical 1,000 Square Foot Project:

- Complete replacement: $8,000-$15,000

- Precision cutting repair: $1,200-$2,400

- Savings: 70-90% compared to replacement

These dramatic cost savings free up budget for other critical maintenance priorities while fully addressing the safety and compliance issues that triggered the repair need in the first place.

Speed and Minimal Disruption

Beyond direct cost savings, precision cutting delivers operational advantages that grinding and replacement cannot match. Most projects are completed in hours rather than days, with walkways immediately accessible after work concludes. There’s no curing time, no barricades blocking access for days on end, and no frustrated residents or customers navigating extensive detours.

For commercial property owners, this minimal disruption means maintaining normal business operations throughout the repair process. For HOAs and municipalities, it means fewer complaint calls and service requests from residents dealing with access limitations.

Environmental Responsibility and Sustainability

Modern property management increasingly considers environmental impact alongside financial factors. Precision cutting aligns with sustainability goals by preserving existing materials rather than contributing to landfill waste.

The environmental advantages include:

- Zero concrete waste sent to landfills

- No production of new concrete (which generates significant CO2 emissions)

- Minimal energy consumption compared to demolition and replacement

- No damage to surrounding landscaping or ecosystems

Organizations working toward sustainability certifications or environmental stewardship goals find that precision cutting supports these objectives while simultaneously reducing costs—a rare win-win scenario.

Legal Liability and Risk Management

Trip and fall incidents represent one of the most common sources of premises liability claims. Property owners face significant legal exposure when known trip hazards remain unaddressed, with settlement costs and legal fees often exceeding six figures for serious injuries.

Florida premises liability law establishes that property owners have a duty to maintain reasonably safe conditions and warn visitors of known hazards. When organizations delay trip hazard repair due to the perceived expense of replacement, they accumulate documented evidence of negligence that strengthens plaintiff cases in the event of injury.

The Cost-Benefit Analysis of Prevention

Investing $2,000 to eliminate documented trip hazards through precision cutting represents prudent risk management compared to the potential costs of litigation. Even a single settlement can exceed the cost of addressing every trip hazard on a property. For municipal decision-makers managing public walkways, this liability protection extends to the entire community they serve.

Florida-Specific Considerations for Sidewalk Repair

Florida’s unique environmental conditions influence concrete performance and repair decisions. The state’s high water table, sandy soil composition, and frequent heavy rainfall create conditions that promote concrete settling and shifting. Tree root growth from Florida’s lush vegetation contributes to additional heaving and displacement.

These factors mean that even relatively new concrete installations can develop trip hazards within just a few years. Understanding that this settling represents a normal consequence of Florida’s geography—rather than poor initial installation—helps property managers make informed decisions about addressing the issue cost-effectively.

With over two decades of experience addressing these Florida-specific challenges, specialized repair providers understand the local conditions that create trip hazards and how to address them permanently using precision cutting technology proven effective across thousands of projects.

Making the Right Decision for Your Property

When evaluating sidewalk grinding, replacement, or precision cutting, consider these key decision factors:

Choose precision cutting when:

- The concrete is structurally sound but uneven

- Budget constraints make replacement impractical

- Minimal disruption to operations is essential

- Professional appearance matters

- ADA compliance is required

- Environmental sustainability is a priority

Consider replacement only when:

- Concrete is severely cracked or crumbling

- Major structural issues exist beyond leveling

- Complete redesign of walkway layout is needed

For the overwhelming majority of trip hazard situations, precision cutting provides the optimal balance of cost-effectiveness, quality results, and minimal disruption.

Take Action to Protect Your Property and Budget

Delaying trip hazard repairs exposes your organization to unnecessary liability while potentially wasting thousands on replacement when cost-effective alternatives exist. Florida Sidewalk Solutions brings proven precision cutting technology and over 20 years of Florida-specific experience to address your concrete sidewalk repair needs efficiently and affordably.

Contact Florida Sidewalk Solutions today for a free assessment of your property’s trip hazards and a detailed cost comparison showing exactly how much precision cutting can save compared to grinding or replacement. Discover why hundreds of property managers, HOAs, and municipal clients have chosen this superior sidewalk grinding alternative to protect their properties, their budgets, and the people they serve.